Spinning creel with rotating and height adjusting functions based on spinning processing

A height-adjusting and functional technology, applied in the field of textile creels, can solve the problems of inability to automatically stop winding, complicated intermediate conversion links, and oversized bobbins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

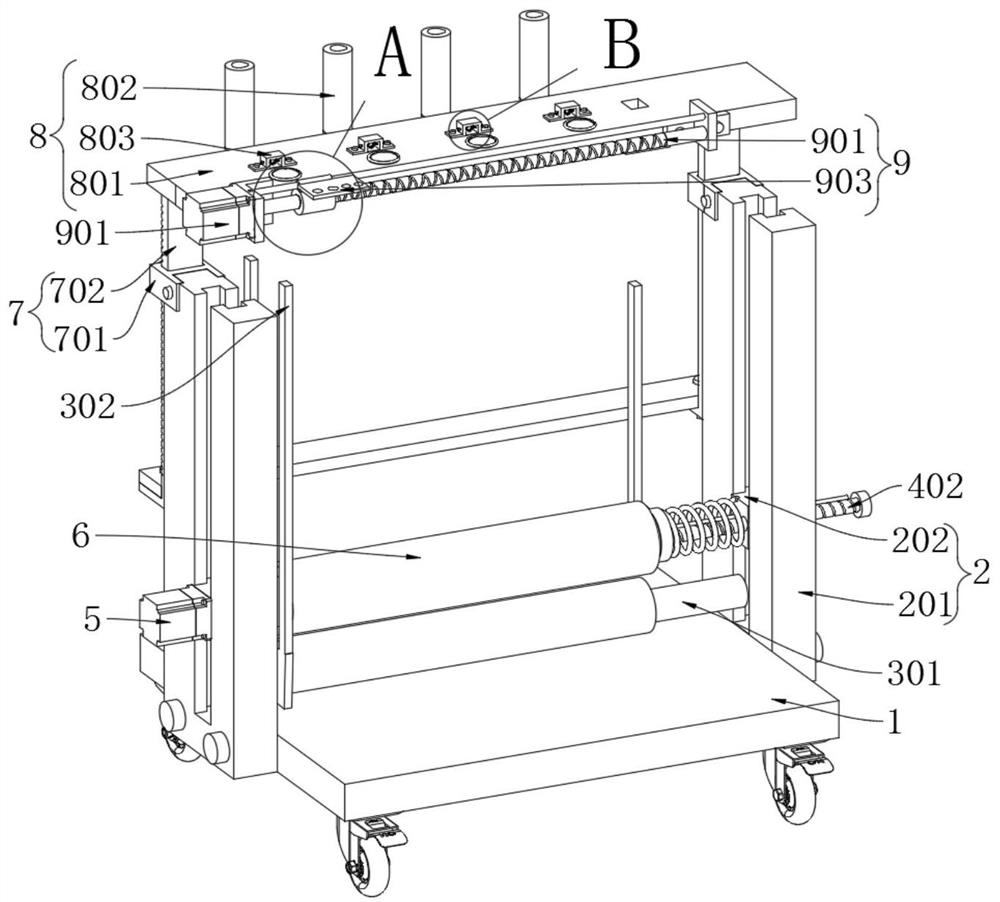

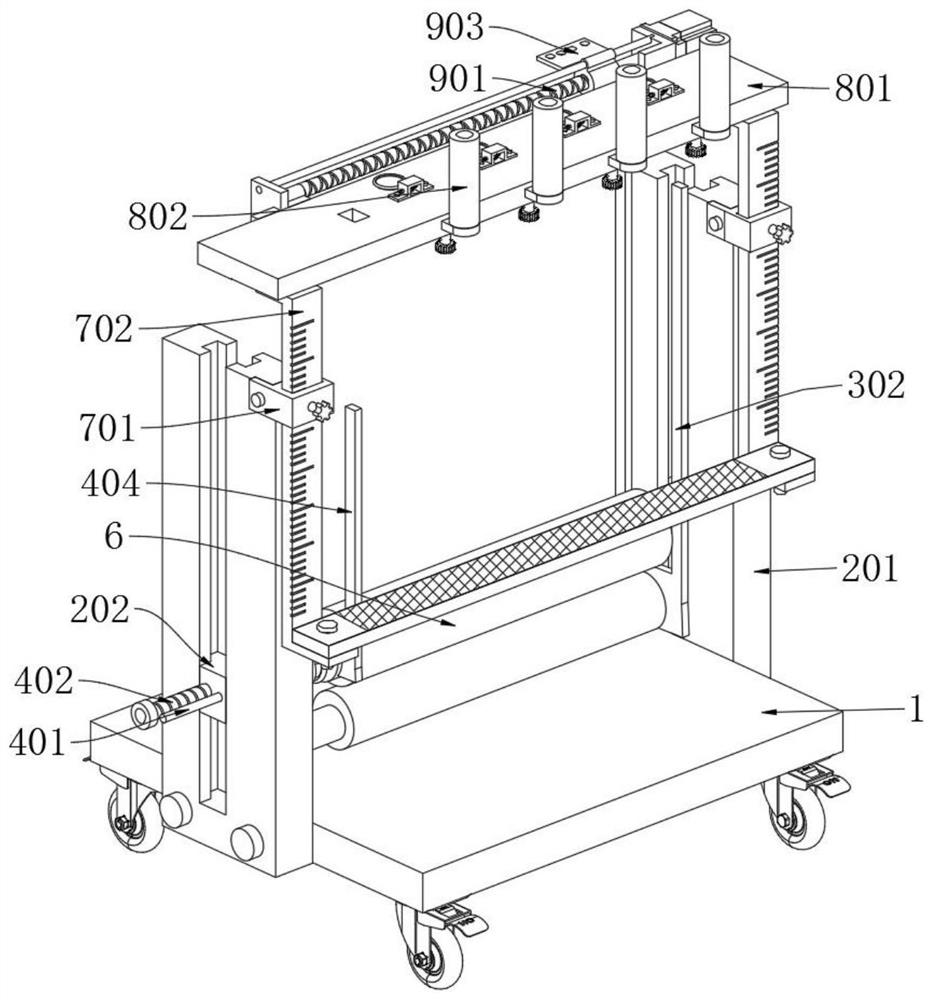

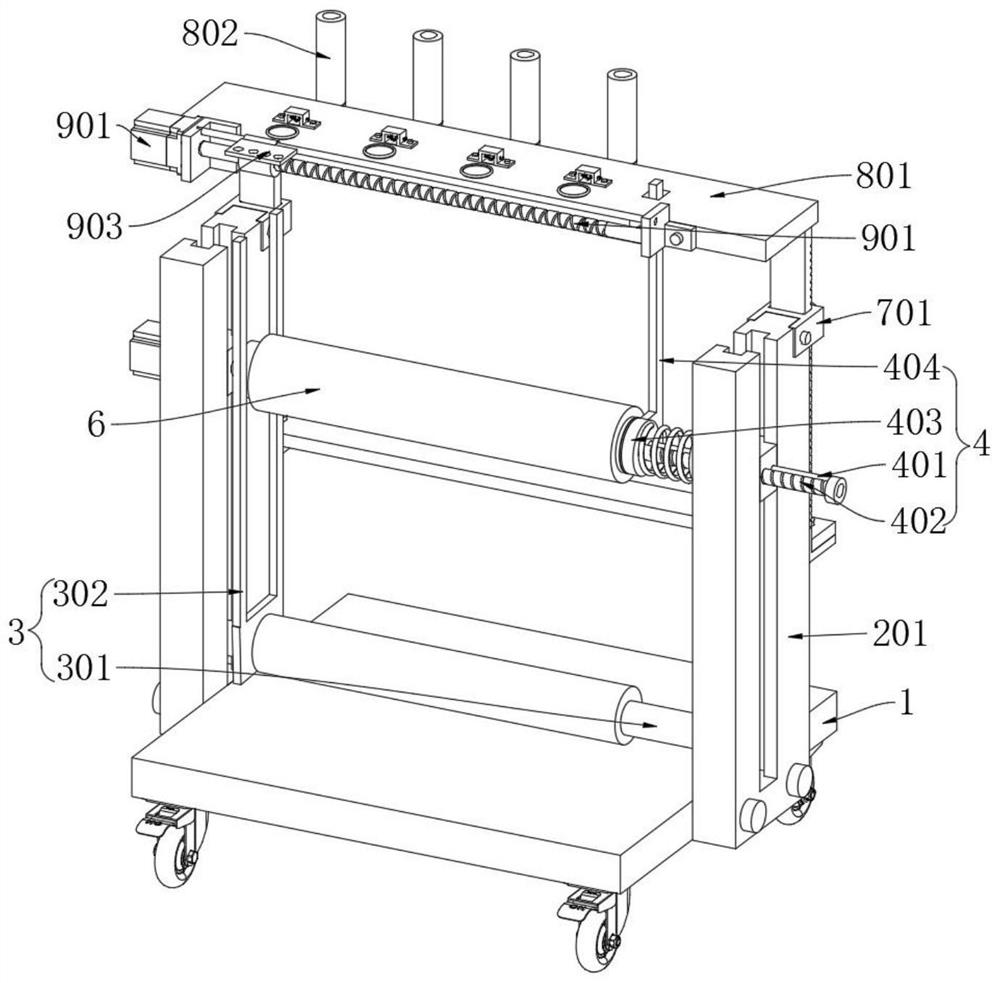

[0044] as attached figure 1 to attach Figure 13 Shown:

[0045] The invention provides a textile creel with rotation and height adjustment functions based on textile processing, which includes a base 1; four universal wheels are installed on the bottom of the base 1, and two supporting mechanisms 2 are symmetrically installed on the base 1. A limit mechanism 3 is installed between the two support mechanisms 2; the support mechanism 2 includes a support rod 201 and a sliding block 202, and a vertical cross-shaped groove is provided on the two rectangular support rods 201, and a vertical cross-shaped groove is installed on the groove. There is a cross-shaped sliding block 202 that is slidably connected. The sliding block 202 runs through the rotating shaft of the sliding rod 401 and the servo motor A5. When in use, the sliding block 202 will drive the roller 6 to slide up and down during the process of sliding up and down, thereby realizing the roller 6. According to the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com