Leveler with safety device and cleaning device

A technology of cleaning device and safety device, which is applied to safety equipment, cleaning methods and utensils, and cleaning method using tools, etc., can solve the problems of no safety protection device, work accident, difficult to clean up dirt and oil stains, etc., and saves money The effect of downtime, prevention of industrial accidents, and guarantee of leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

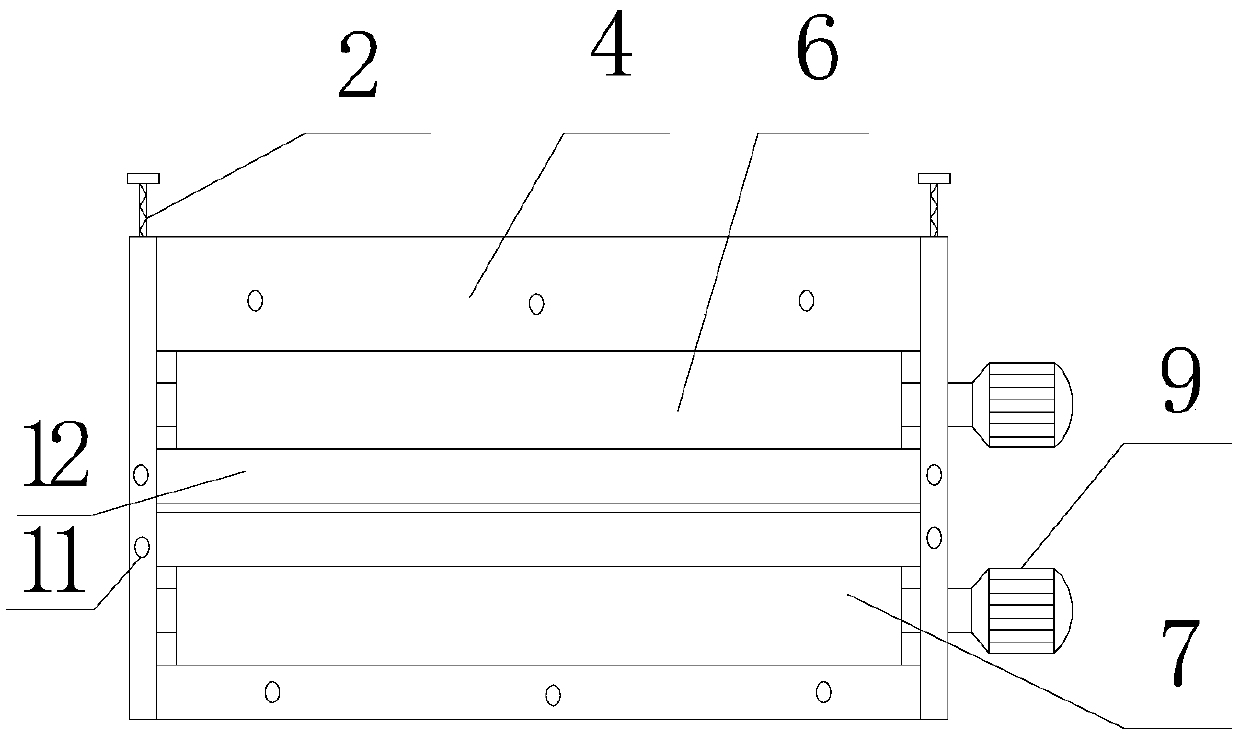

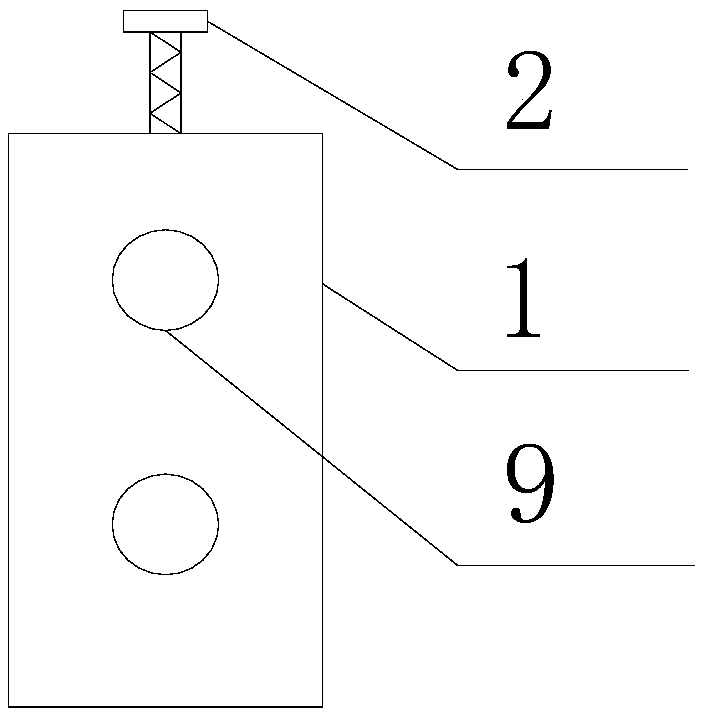

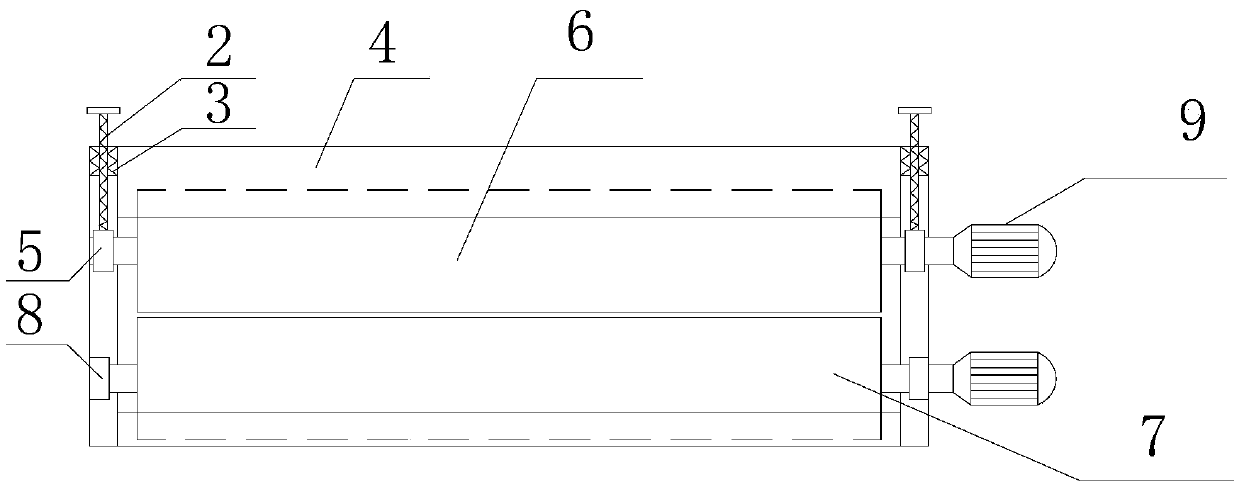

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention is a leveler with a safety device and a cleaning device, including a leveler body 1, an adjustment screw 2, an adjustment screw nut track 3, a friction grinding wheel layer 4, a fixed ring 5, an adjustable roller 6, a roller Shaft 7, fixing slot 8, motor 9, fixing screw 10, rivet 11 and safety protection plate 12, said adjusting screw rod 2 is directly connected with fixing ring 5, and is interspersed and engaged with adjusting screw nut track 3 through thread, said adjusting The screw nut track 3 is directly welded and fixed on the inner surface of the leveler body 1, the friction grinding wheel layer 4 is fixedly installed on the inner surface of the leveler body 1 by fixing screws 10, and the fixing ring 5 is directly fixed on the adjustment The lower end of the screw 2, the adjustable roller 6 is fixedly installed inside the leveler body 1 through the fixing ring 5, the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com