Device for automatically cleaning and transporting faeces in sheep house

A technology of automatic cleaning and transportation device, applied in animal houses, applications, animal husbandry, etc., can solve problems such as labor and time-consuming, achieve good manure cleaning effect, simple and reasonable equipment structure, and solve the effect of poor working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

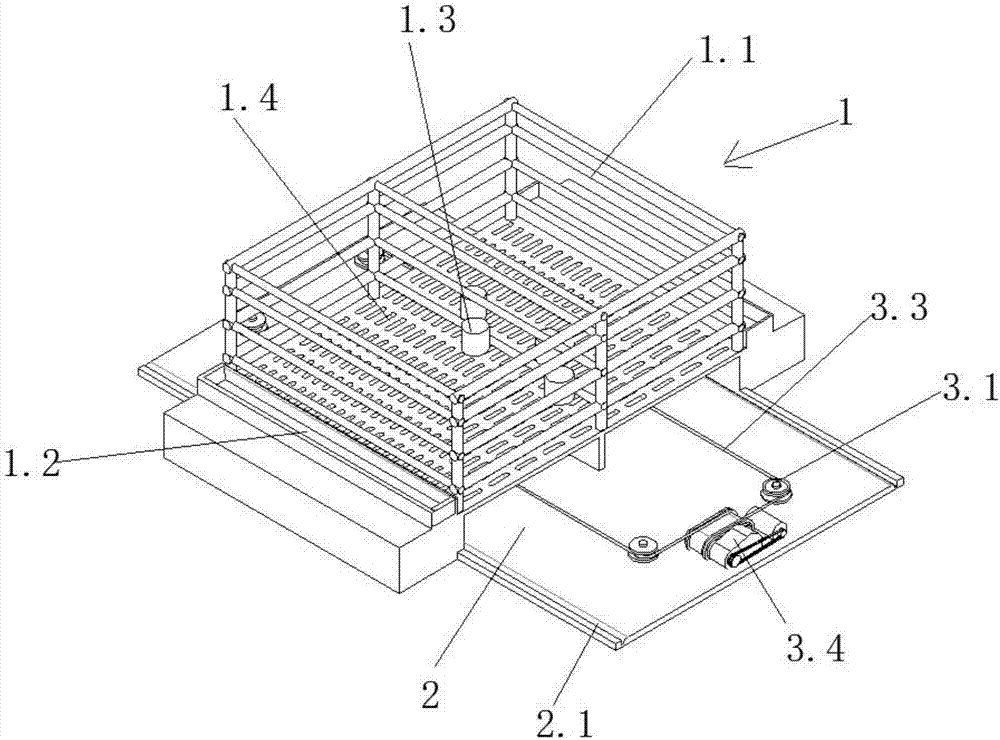

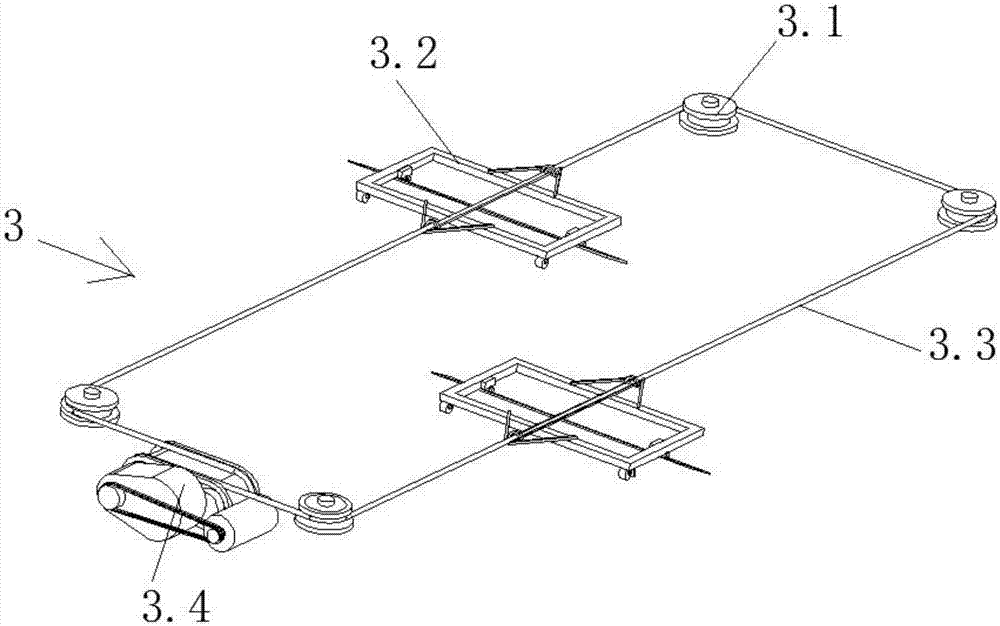

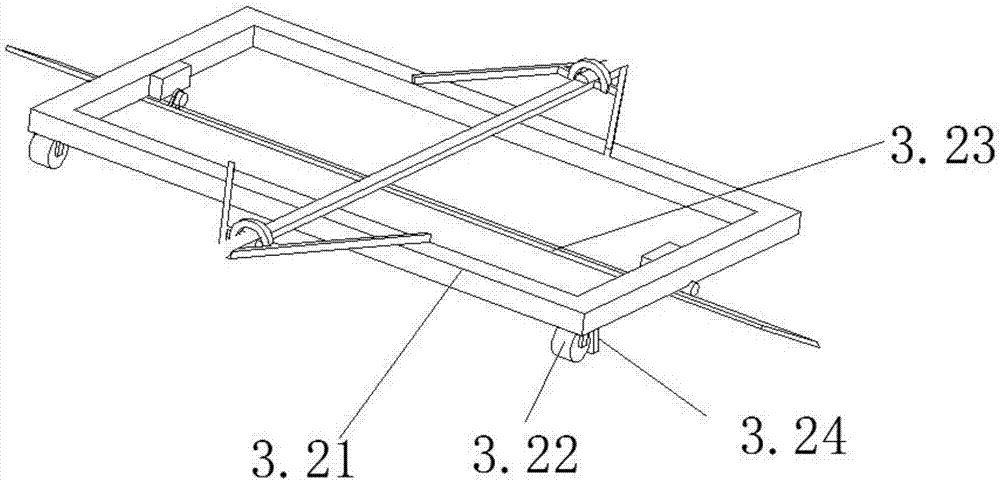

[0027] Such as figure 1 and 2 As shown, a sheep house feces automatic cleaning and transportation device includes a sheep house 1, a septic collection tank 2 provided at the bottom of the sheep house, and a gathering device 3 provided at the bottom of the septic tank 2, wherein the sheep house 1 includes a fence 1.1, a fence 1.1 Feed trough 1.2 set outside, fence 1.1 Drinking trough 1.3 set inside, slatted floor 1.4, sheep are raised inside the fence 1.1, the sheep eat and drink through the feed trough 1.2 and drinking trough 1.3, and the feces during growth pass through the slit The floor 1.4 falls into the septic tank 2, and the gathering device 3 is used to collect and clean up the feces accumulated in the septic tank 2, wherein, such as figure 2As shown, the gathering device 3 includes four fixed pulleys 3.1 arranged in the shape of a "mouth" alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com