Leveling Natural Stone Paint External Insulation Decorative Panel Spray Painting Production Line

A natural stone and external thermal insulation technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problem of difficulty in ensuring the plane accuracy of the surface layer, poor surface flatness of the decorative board, and easy accumulation of dust on the surface of the decorative board. and other problems, to achieve the effect of ecological and environmental protection production, easy to recycle paint, easy to control flow and pressure respectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

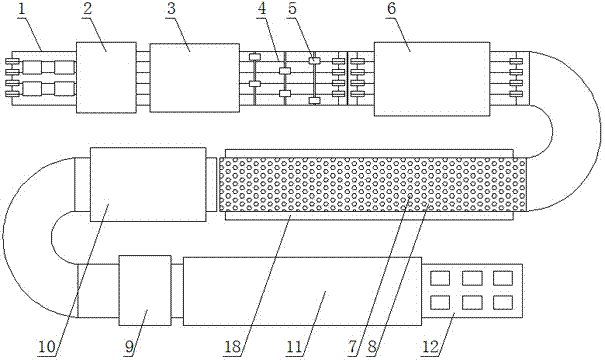

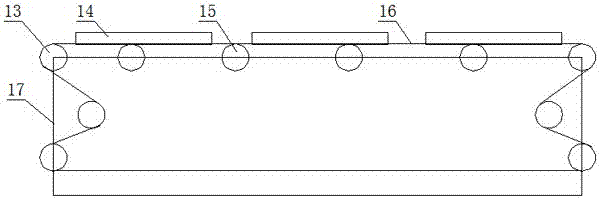

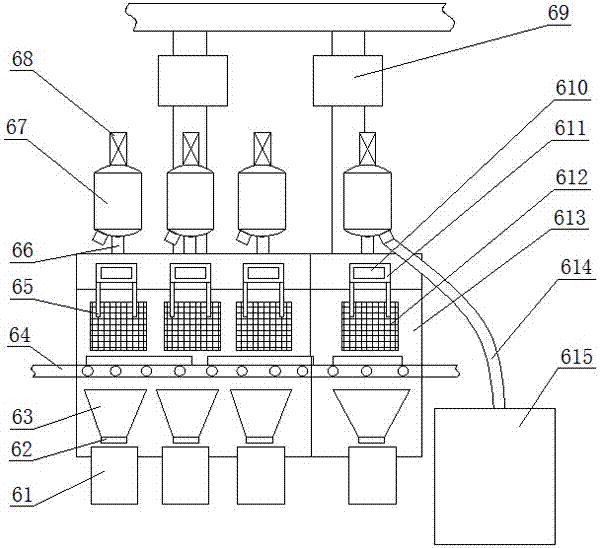

[0022] Such as figure 1 Shown: the spraying production line of leveling natural stone paint external thermal insulation decorative board of the present invention comprises substrate conveyor belt 1, primer spraying machine 2, conveyor belt 4 after primer spraying, multi-color natural stone paint spraying machine 6, stone paint Conveyor belt 8 after spraying, stone paint layer drying chamber 10, finish paint spraying machine 9, conveyer belt 12 after spraying finish paint, conveyer belt 4 after described primer is sprayed is provided with primer drying chamber 3 and some cooling blowers 5, After the primer is sprayed, the conveyor belt 4 passes through the primer drying chamber 3, and a cooling fan 5 is arranged above the conveyor belt 4 after the primer is sprayed by the frame body. The conveyor belt 8 after spraying the stone paint is a flexible broadband conveyor belt with air holes 7, and a gas vibrator 18 is arranged under the conveyor belt, and a topcoat drying chamber 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com