Movable tool for battery pack assembling

A technology for movable tooling and battery packs, which is used in battery assembly, secondary battery manufacturing, auxiliary devices, etc., and can solve the problems of misalignment of battery and battery tabs, poor quality, and positive battery pack codes, so as to ensure quality and guarantee The effect of levelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

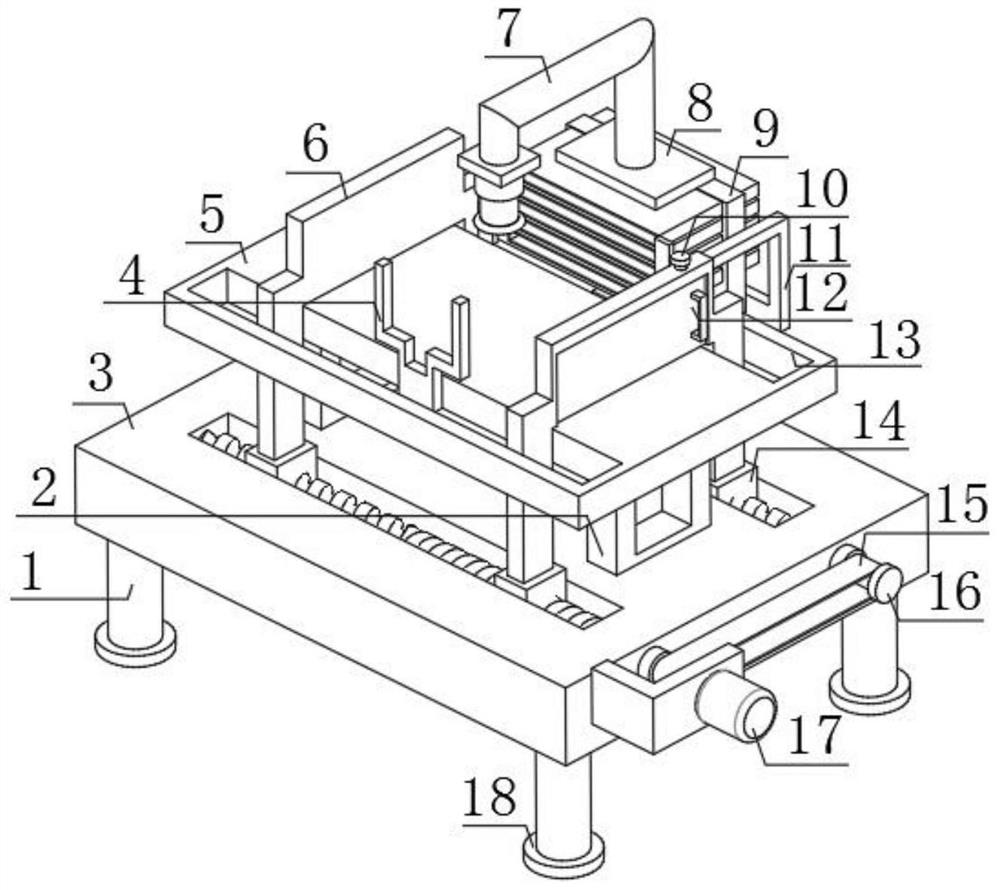

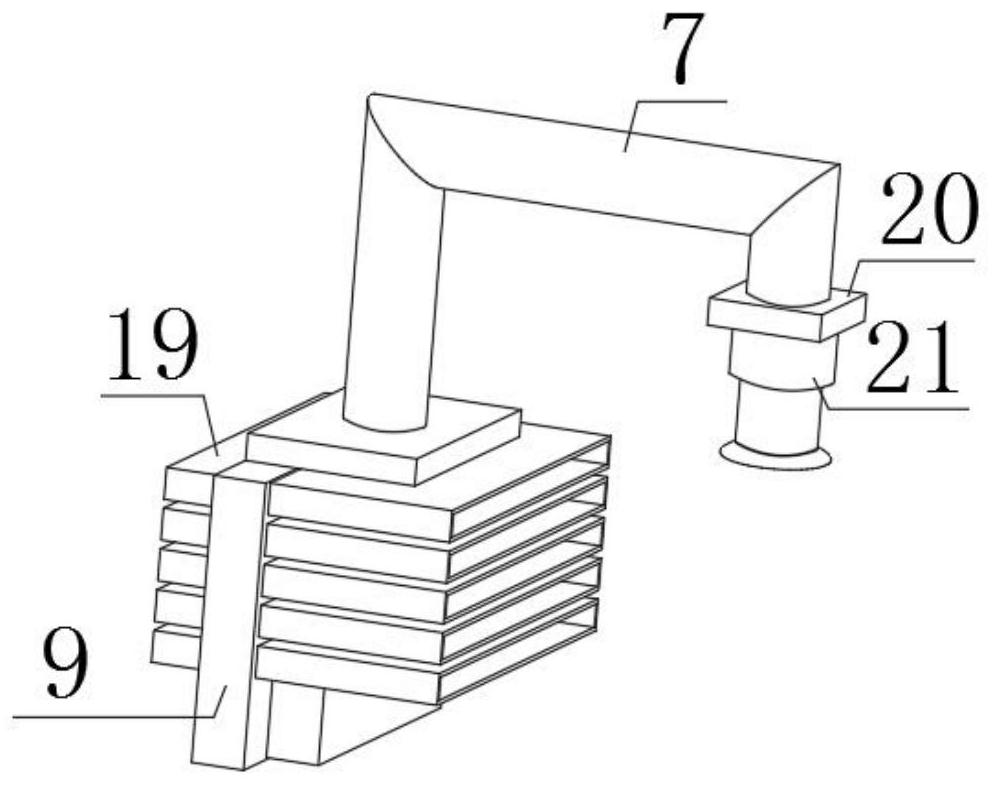

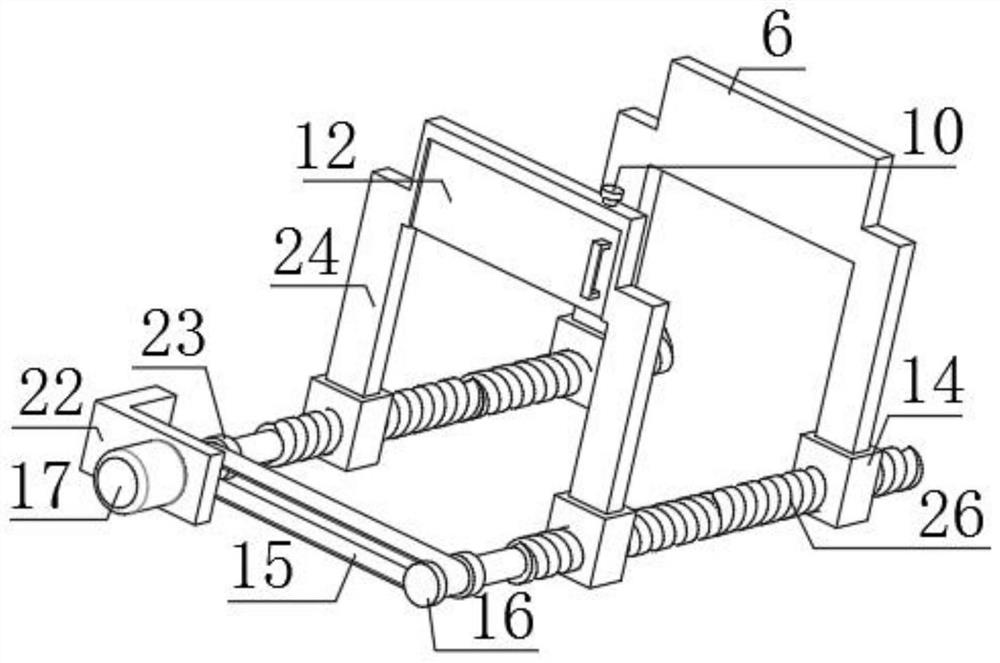

[0028] refer to Figure 1-4 , a movable tooling for battery pack assembly, comprising a bottom plate 3, support plates 2 are fixedly connected to both sides of the top outer wall of the bottom plate 3, and the same horizontal plate 5 is fixedly connected to the top outer walls of the two support plates 2, and the horizontal plate 5 One side of the top outer wall is fixedly connected with a fixed frame 9, and the inner wall of the fixed frame 9 is fixedly connected with equidistantly distributed lead-in boxes 19, and the top outer wall of the lead-in box 19 is fixedly connected with a mounting plate 8. Fixedly connected with a mounting rod 7, one end of the mounting rod 7 is fixedly connected with a connecting plate 20, the bottom outer wall of the connecting plate 20 is provided to connect the first electric telescopic rod 21, and one end of the electric telescopic rod extension rod is fixedly connected with a backing plate, and the top of the bottom plate 3 Both sides of the ...

Embodiment 2

[0039] refer to Figure 5 , a movable tooling for battery pack assembly, comprising a bottom plate 3, support plates 2 are fixedly connected to both sides of the top outer wall of the bottom plate 3, and the same horizontal plate 5 is fixedly connected to the top outer walls of the two support plates 2, and the horizontal plate 5 One side of the top outer wall is fixedly connected with a fixed frame 9, and the inner wall of the fixed frame 9 is fixedly connected with equidistantly distributed lead-in boxes 19, and the top outer wall of the lead-in box 19 is fixedly connected with a mounting plate 8. Fixedly connected with a mounting rod 7, one end of the mounting rod 7 is fixedly connected with a connecting plate 20, the bottom outer wall of the connecting plate 20 is provided to connect the first electric telescopic rod 21, and one end of the electric telescopic rod extension rod is fixedly connected with a backing plate, and the top of the bottom plate 3 Both sides of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com