Method for leveling tungsten plate with high straightness

A flatness and leveling technology, which is applied in the leveling field of high-flatness tungsten plates, can solve the problems that cannot meet the thermal leveling requirements of tungsten plates, and achieve the effect of preventing oxidation and ensuring the leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

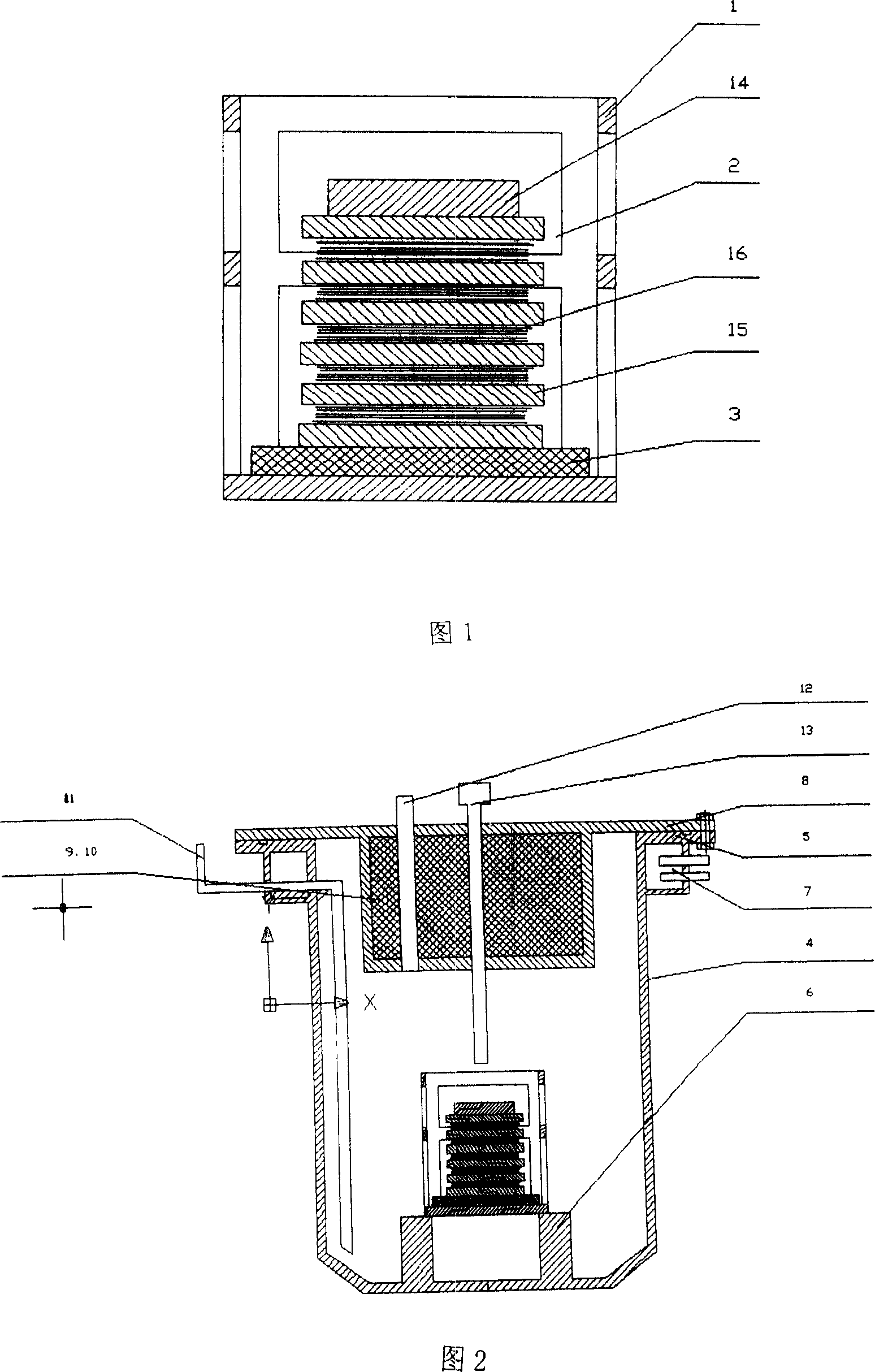

[0021] Take a tungsten sheet with a thickness of 0.2mm, a counterweight tungsten block 14, a flatness of ≤±0.02mm, and a high-temperature molybdenum alloy 15 as a leveling pressing block, and the leveling tungsten plates (sheets) 16 are neatly placed on the pressing blocks In the middle, a tungsten block is placed on top of the top layer as a counterweight. The leveling pressing block, tungsten sheet, and counterweight are placed on the silicon carbide heat-resistant plate of the material basket as a whole; then the material basket is placed on the support platform of the leveling isolation protection tank; and then the leveling isolation protection tank is hoisted into the vertical resistance In the furnace, hydrogen gas is introduced, under the heating condition of 850℃×1h+1100℃×2h, the heating and leveling is carried out, and the leveling is completed after cooling to room temperature.

Embodiment 2

[0023] Take a tungsten plate with a thickness of 1.0mm, and other conditions are the same as in Example 1. Use TZM alloy as a leveling block with a flatness of ≤±0.02mm, and heat it at 950°C×1h+1200°C×2h. Heating and leveling, cooling to room temperature, complete leveling, tungsten sheet flatness ≤ ± 0.02mm, not oxidized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com