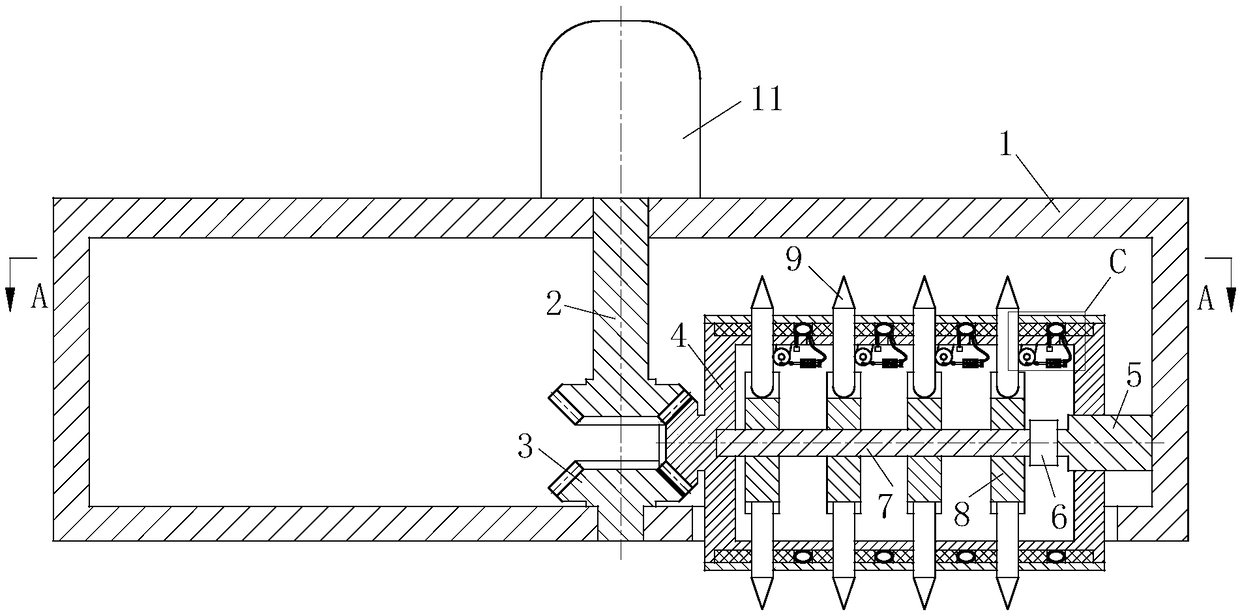

Expressway pavement repair device

A technology for road surface repair and expressway, applied in the direction of road repair, roads, roads, etc., can solve the problems of low work efficiency, troublesome rut repair on asphalt pavement, high repair cost, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

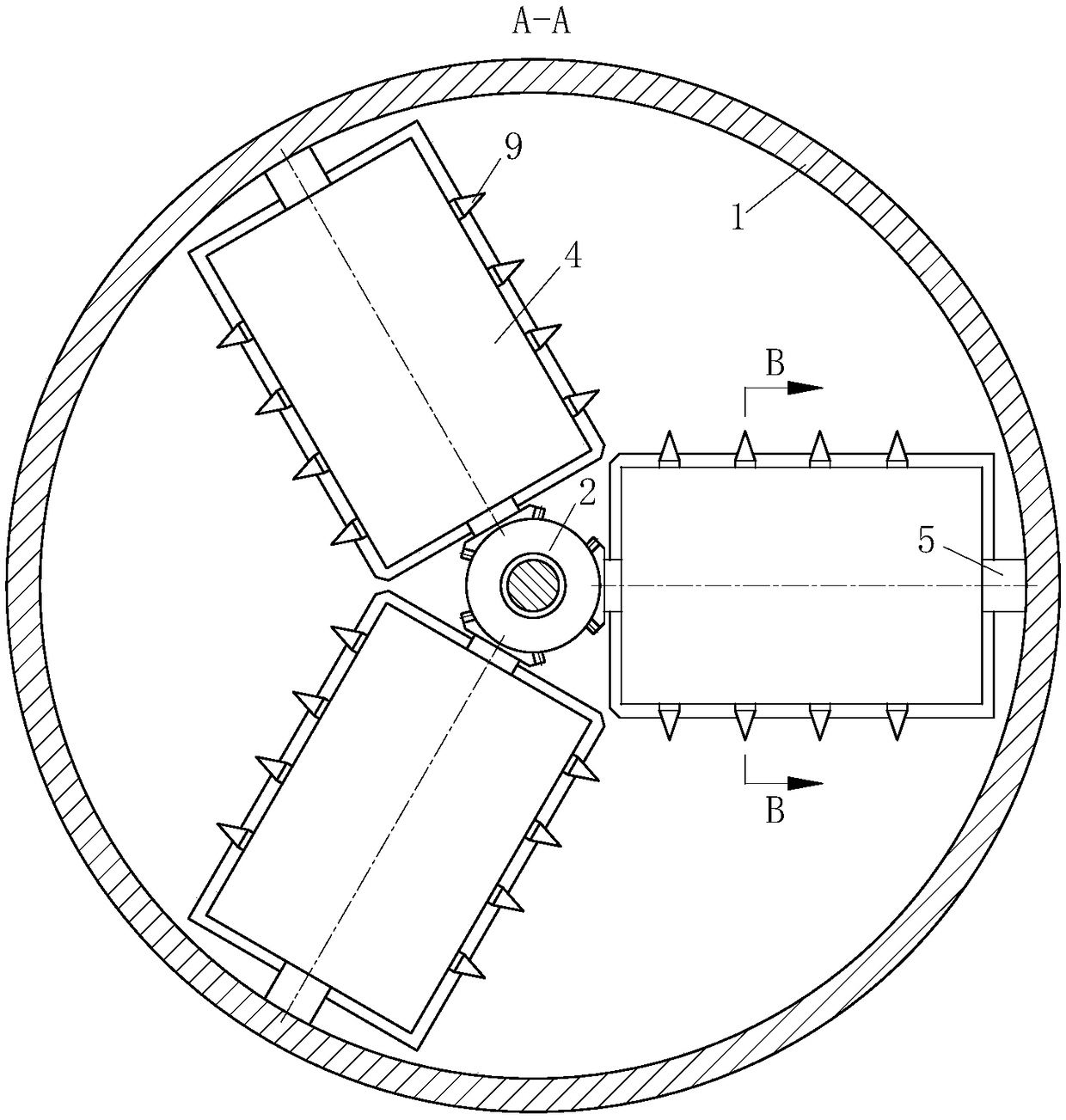

Method used

Image

Examples

Embodiment approach

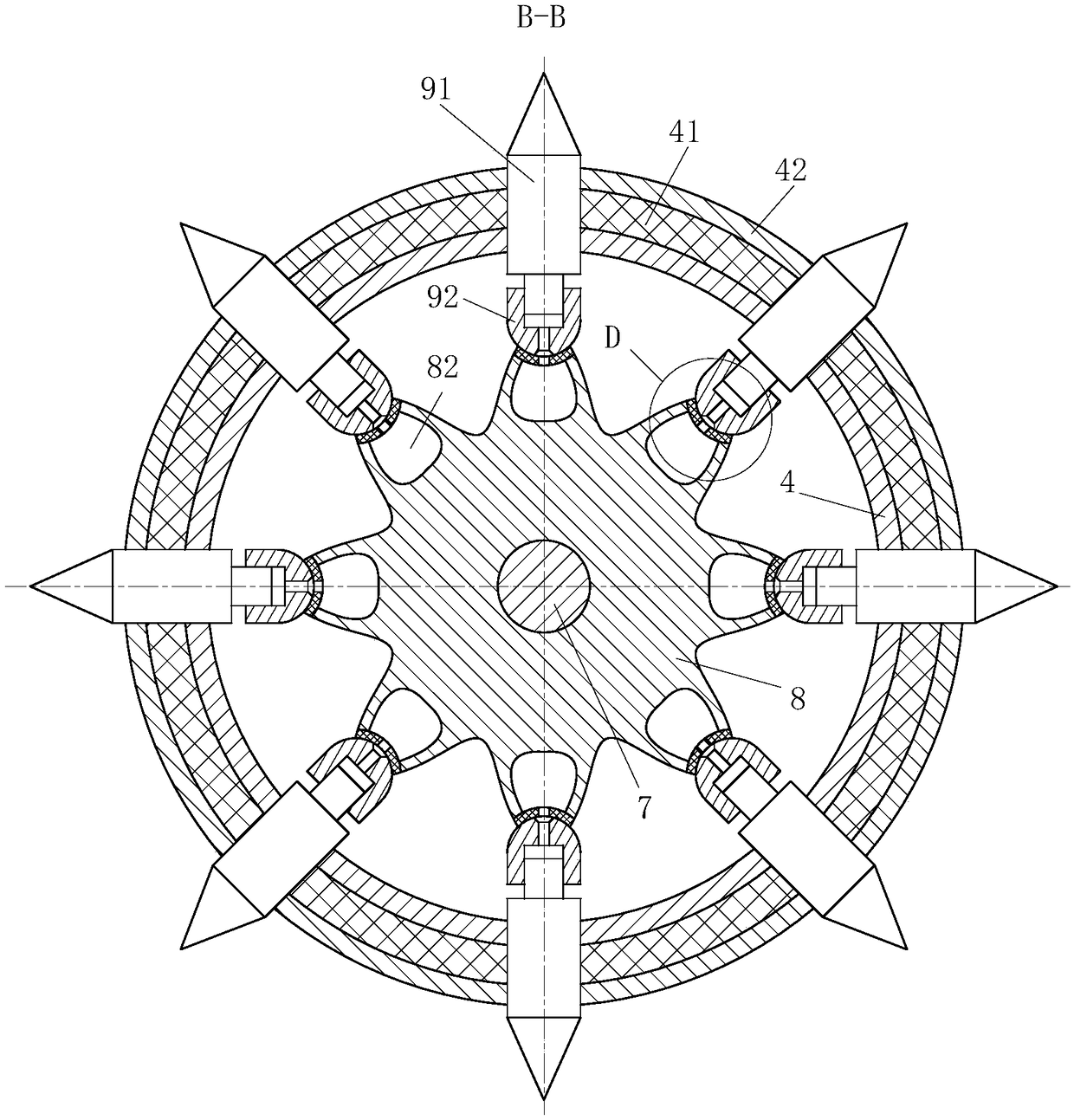

[0026] As an embodiment of the present invention, the protrusion of the flower-shaped cam 8 is provided with an arc-shaped shrapnel 81; the arc-shaped shrapnel 81 is made of high-temperature-resistant rubber; When pressing the arc-shaped shrapnel 81, the arc-shaped shrapnel 81 is depressed after being squeezed, and then fits with the round end surface of the perforated steel needle 9, so that the round end surface of the perforated steel needle 9 will not Sliding relative to the surface of the flower-shaped cam 8, the impact force can be transmitted to the transmission shaft 7, preventing the perforating steel needle 9 from bending due to the inclined force, thereby improving the service life of the perforating steel needle 9.

[0027] As an embodiment of the present invention, a No. 1 through hole 811 is set in the middle of the arc-shaped shrapnel 81; a No. 1 cavity 82 is set on the protrusion of the flower-shaped cam 8; during operation, the round head of the punching steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com