Automotive central defrosting air pipe and mounting structure for same and instrument board

A technology for instrument panels and air ducts, applied in the field of central defrosting duct structures, can solve problems such as poor sealing effect, misalignment of air outlets and central defrosting grilles on the instrument panel, etc., to ensure manufacturability and strengthen strength , to reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by implementing examples, in conjunction with accompanying drawing, technical scheme of the present invention is described further:

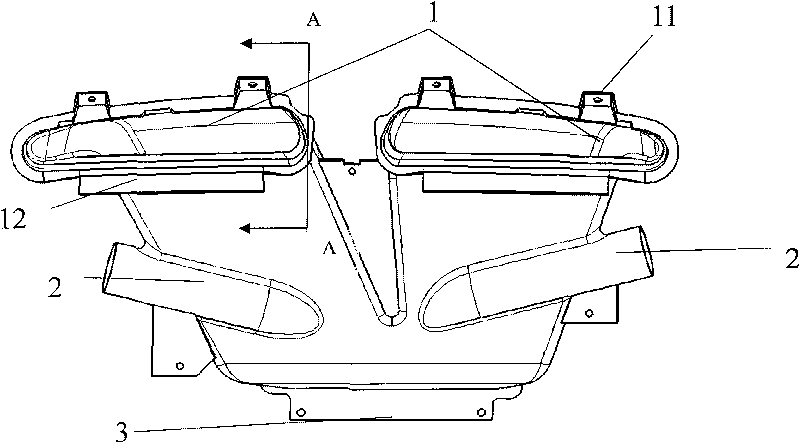

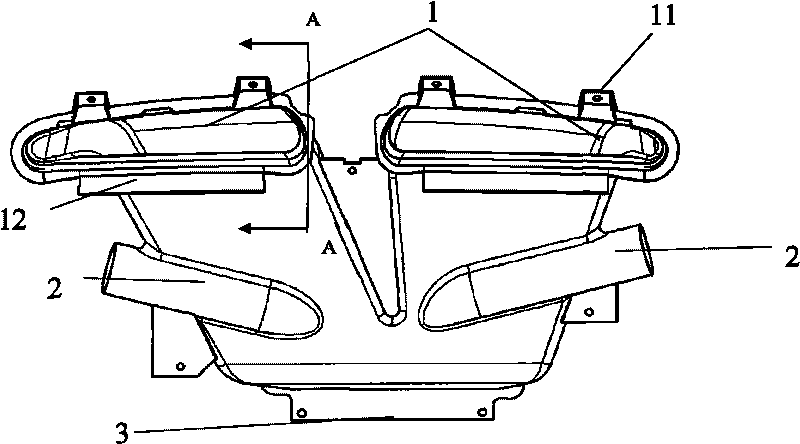

[0015] see figure 1 The air duct body 6 of the central defrosting air duct is a blow-molded integral pipe, and the lower end of the air duct body 6 is an air inlet 3, which is connected to the blowing surface air duct and then connected to the air outlet of the HVAC. The upper end is separated to the left and right to form two symmetrical air outlets 1 with oblong cross-sections, and there are two circular side defrosting branch air ducts 2 on both sides of the middle part of the air duct body.

[0016] Four connection blocks 11 with mounting holes are formed on the outside of the upper edge of the air outlet 1, and a dislocation-preventing flange 12 is formed on the lower edge of the air outlet 1, and the dislocation-preventing flange 12 has a shape relative to the air outlet. The flared shape protrudes outward.

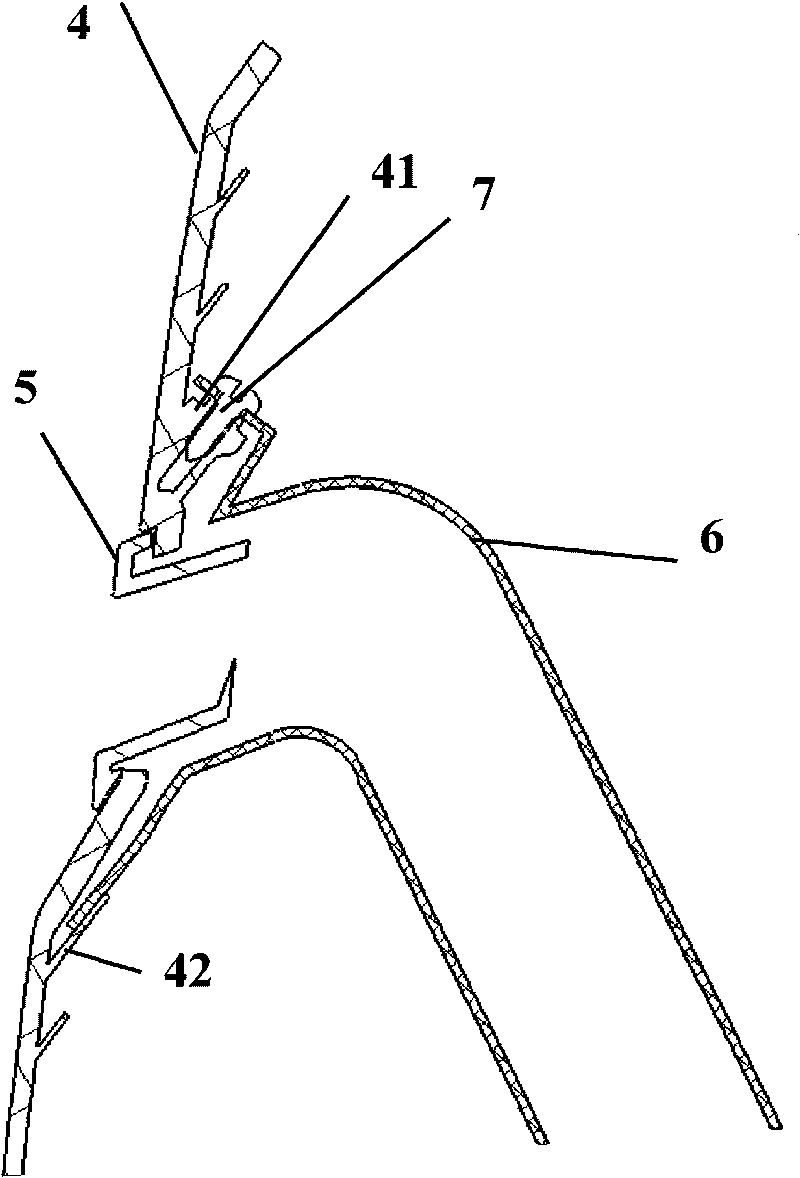

[0017] see fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com