Fuel rod cladding, fuel rod and fuel assembly

A technology for fuel elements and fuel assemblies, applied in the field of nuclear energy, can solve problems such as cladding formation defects, and achieve the effects of reducing the risk of failure, avoiding corrosion damage, and reducing hydraulic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

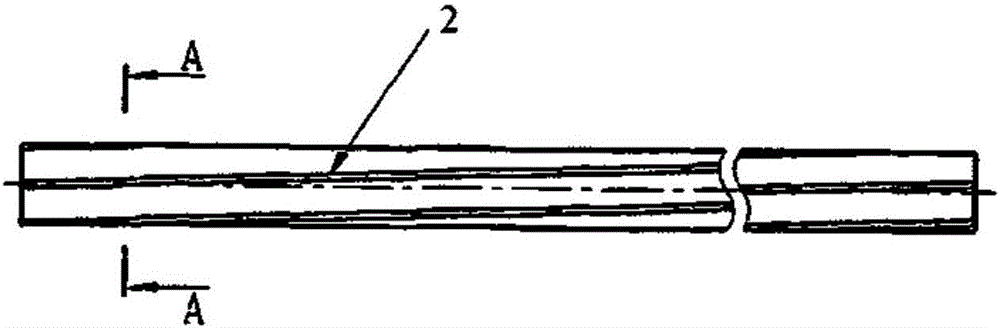

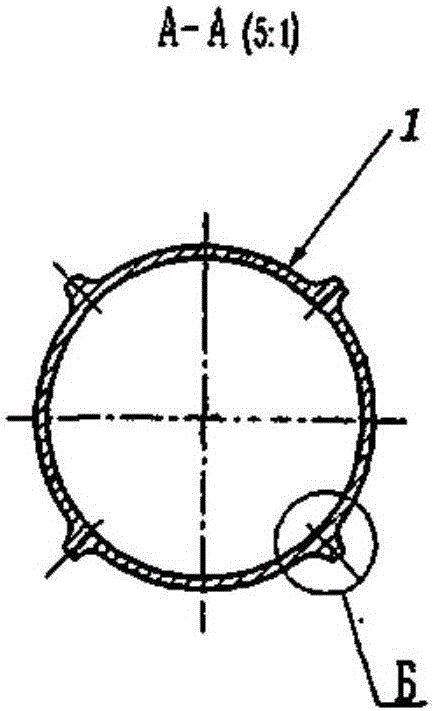

[0051] Tubes with 4 helical fins for the manufacture of fuel element claddings were made by cold rolling ЭП823-Ш billet tubes.

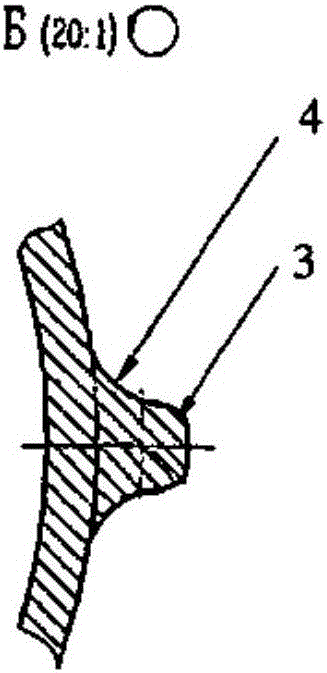

[0052] The diameter of the cladding along the fins is 13.5 mm, the wall thickness of the cladding is 0.4 mm, and the inner diameter of the cladding is 11.2 mm. The height of the fins is 0.75 mm, the width at half the height of the fins is 0.75 mm, and the ratio of fin height to wall thickness is 1.85. The cross section of the fin is trapezoidal with an inner rounded corner, the radius of the inner circle is 0.2 mm, and the radius of the rounded portion of the trapezoid is 0.7 mm. The opening angle of the fins is 30°. The fins were wound in a helix (clockwise winding) with a spacing of 750mm between the fins.

[0053] The finished cladding is filled with uranium dioxide-based nuclear fuel and sealed with upper and lower ends (plugs) to make fuel elements.

[0054] In order to make fuel assemblies, the assembled fuel elements are installed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com