Preparation process of palladium electrode ion polymer and metal composite

A technology of metal composite materials and ionic polymers, applied in metal material coating technology, liquid chemical plating, coating, etc., can solve the problems of limited deformation capacity, long preparation cycle, low efficiency, etc., and achieve excellent actuation performance , reduced time, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

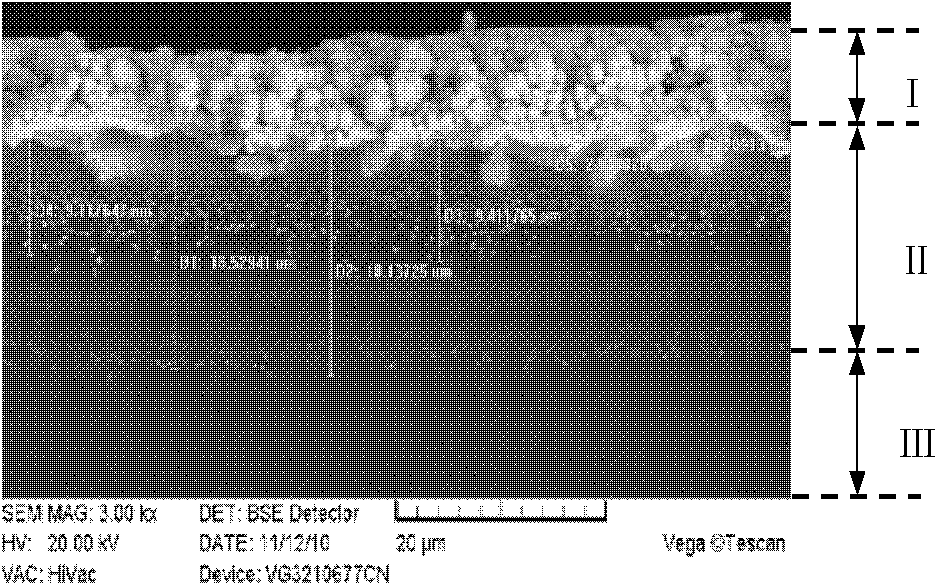

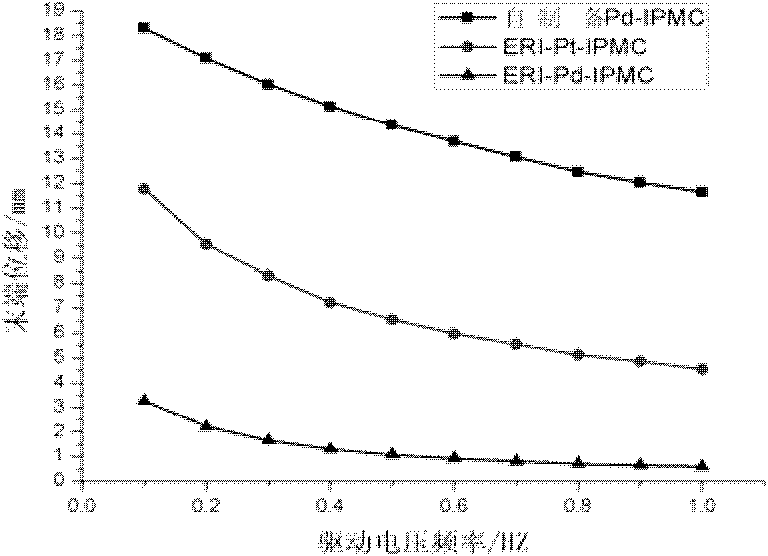

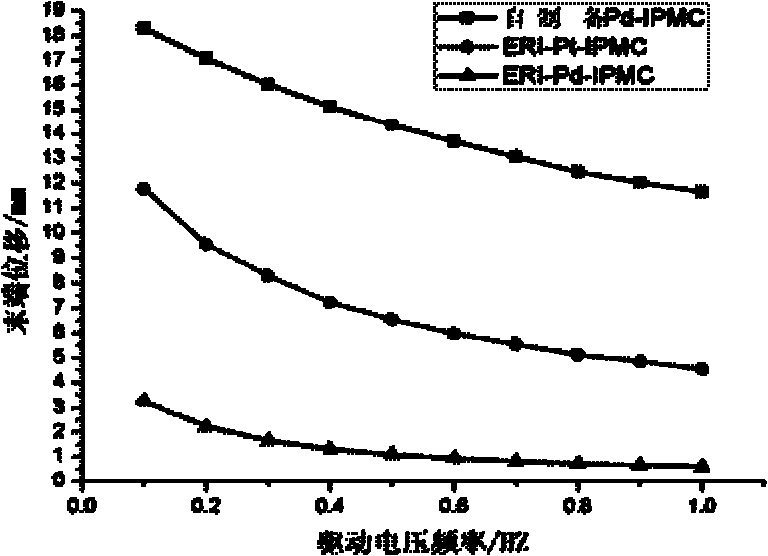

Image

Examples

Embodiment 1

[0027] (1) Base membrane pretreatment:

[0028] Cut out a Nafion-117 ion exchange membrane with a size of 6cm×6cm as the base material; use 1200# sandpaper to polish and roughen it, one side for 10 minutes, observe the surface under the light to become rough and have no obvious bright spots, and you can end the polishing; ultrasonic cleaning The instrument is set at 60°C and the power is 250W. After cleaning the matrix film for 30 minutes, put it into 200ml, 2mol / L HCl, boil it in a water bath at 90°C for 30 minutes, and then put it in a water bath of 200ml deionized water at 90°C for 30 minutes to make it fully swelling. Finally, the pretreated Nafion membrane was stored in deionized water.

[0029] (2) Immersion reduction plating: Immersion reduction plating is to deposit a metal catalytic layer on the two surfaces of the base film, which is the chemical reaction basis of the next electroless plating. Soak the pretreated base film in [Pd(NH 3 ) 4 ] Cl 2 In salt solution...

Embodiment 2

[0041] (1) Base membrane pretreatment:

[0042] A Nafion-117 ion exchange membrane with a size of 6cm×6cm was used as the base material. The difference from Example 1 was that the base membrane was polished with 600# sandpaper for 5 minutes on one side.

[0043] (2) Immersion reduction plating:

[0044] 1. ion exchange: different from Example 1: the palladium salt solution concentration is 0.008mol / L, in this palladium salt solution, by every gram of Pd (NH 3 ) 4 Cl 2 Add 60ml of ammonia water with a mass concentration of 25%, that is, use 0.34g [Pd(NH 3 ) 4 ]Cl 2 , 170ml of deionized water, 20ml of ammonia water (25%) is configured as a palladium salt solution; the soaking time at room temperature is 1.5h.

[0045] ②Ion reduction: The difference from Example 1 is that the ultrasonic cleaner is set at 40°C; a beaker containing 160ml of deionized water is put into the ultrasonic cleaner, and 0.5ml of ammonia water (25%) is added; In the beaker, add 4ml of 3% NaBH 4 solu...

Embodiment 3

[0052] (1) Base membrane pretreatment:

[0053] A Nafion-117 ion exchange membrane with a size of 6cm×6cm was used as the base material. The difference from Example 1 was that the base membrane was polished with 600# sandpaper for 5 minutes on one side.

[0054] (2) Immersion reduction plating:

[0055] 1. ion exchange: different from Example 1: in this palladium salt solution, by every gram of Pd (NH 3 ) 4 Cl 2 Add 45ml of ammonia water with a mass concentration of 25%, that is, use 0.34g [Pd(NH 3 ) 4 ]Cl 2 , 140ml deionized water, 15ml ammonia water (25%) is configured into palladium salt solution;

[0056] 2. Ion reduction: Different from Example 1, put the beaker filled with 160ml deionized water into the ultrasonic cleaner, add 0.7ml ammonia water (25%); put the base film into the beaker, add 2ml 7% NaBH 4 solution; then add 2ml of 3% NaBH every 30min 4 After 1.5 hours, the ion reduction is completed, and the ion membrane is rinsed with deionized water.

[0057]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com