Foam elimination device for vacuum oil purification

A foam and vacuum technology, applied in the direction of foam dispersion/prevention, can solve problems such as safety accidents, threats to staff safety, fire threats to equipment personal safety, etc., to achieve the effect of eliminating foam and advanced and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

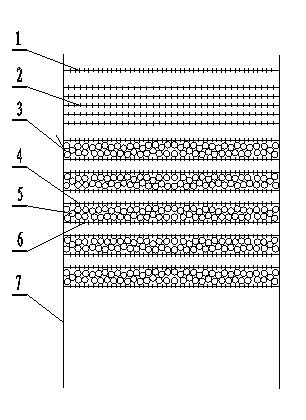

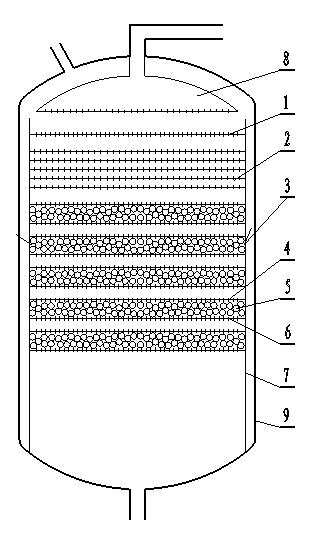

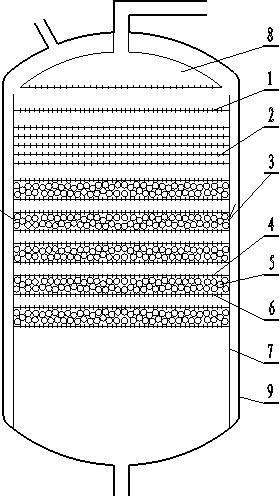

[0013] see figure 1 , figure 2 , Vacuum clean oil foam elimination device. It is composed of a deflector, a stainless steel screen, a chromatography device, and a bracket 7, and the bracket 7 is connected with a deflector 1, five layers of stainless steel screens 2, and five sets of chromatography devices 3 sequentially from top to bottom. The deflector 2 is made of a stainless steel plate with a thickness of 1.5mm, and a plurality of holes with a diameter of 3mm are processed on the plate. The diameter of the hole on the stainless steel screen 3 is 1 mm, and the distance between the five layers of stainless steel screen 3 is 10 mm. The chromatography device 3 is composed of an upper deflector 4, a high-elastic fiber ball 5, and a lower deflector 6 connected in sequence, and the distance between the upper deflector 4 and the lower deflector 6 is 30mm, and the middle is placed There are high-elastic fiber balls 5 with a diameter of 10 mm, and the distance between five sets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com