Automatic chicken manure organic fertilizer production equipment and process method thereof

An automatic production and organic fertilizer technology, applied in the directions of organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems that the eggs of pests cannot be killed, cannot release effective fertilizer, and the growth of crops is unfavorable, and achieves convenient equipment purchase and installation. Easy operation and smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

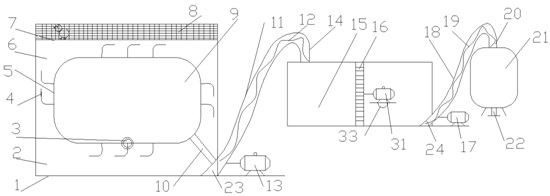

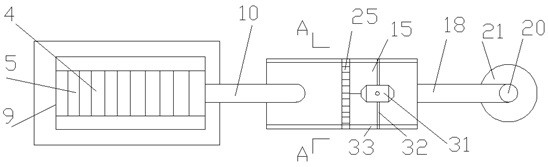

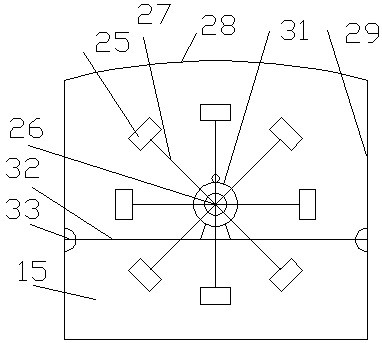

[0031] Embodiment 1, with reference to accompanying drawing, on the top of the chicken manure tank of the equipment of the present invention is a chicken coop, in the chicken coop, there are live chickens raised, and the live chickens defecate and fall to the belt, and the belt is equipped with a scraper, which is rotated and scraped by the belt. The board unloads the chicken feces to the first lifting screw shaft 12 to the rake mixing bin 15, and the rake mixing bin 15 is sprayed with microbial EM complex bacteria on the surface of the chicken feces. The ratio of microbial EM complex bacteria to water is 1:1000 times. Pulling back and forth by the rake stirring wheel 16, the rake stirring wheel 16 continuously stirs the chicken urine evenly, and the top cover 28 is arranged on the top of the rake stirring bin 15, so that the turning rake stirring bin 15 is sealed, fermented, sterilized, and homogenized. Two lifting screw shafts 19 deliver the chicken droppings in the rake mix...

Embodiment 2

[0033] Embodiment 2, with reference to embodiment 1, with reference to accompanying drawing, support 9 is installed in the septic tank 2, supports 9 support belts 5 operation, turns over and rakes mixing chamber 15 and installs blower fan to dry chicken excrement. The second hoistway 18 transports the chicken excrement in the rake mixing chamber 15 to the anaerobic drying tank 21, and adds hot air to the anaerobic drying tank 21 to dry the chicken excrement, and the finished fertilizer chicken excrement is discharged from the discharge port 22 to obtain lumps The finished fertilizer of organic fertilizer. A channel is installed at the discharge port 22 to lead to the pulverizer for crushing, and then sieve and granulate to form round and / or oblong pellets. The top cover 28 is equipped with a chimney, and the chimney is equipped with a dust collector, and the flue gas is recovered to the rake stirring bin 15 for circulation after passing through the dust collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com