Heavy duty plate feeder capable of realizing smooth transmission

A plate feeder, heavy-duty technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy shock and vibration, heavy maintenance and repair workload, and unstable transmission, so as to eliminate shock and The effects of vibration, reliable operation, and simple structure of the chain belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

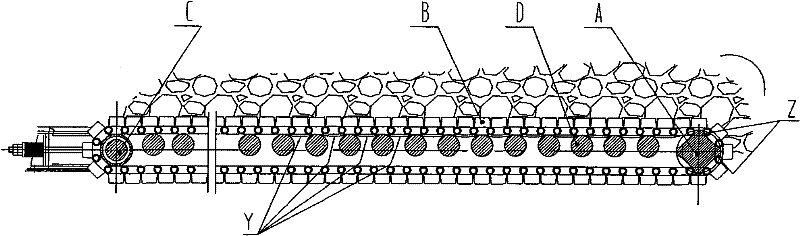

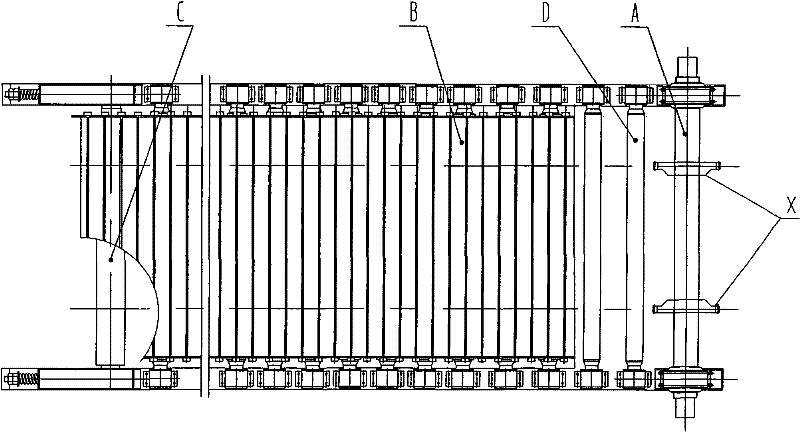

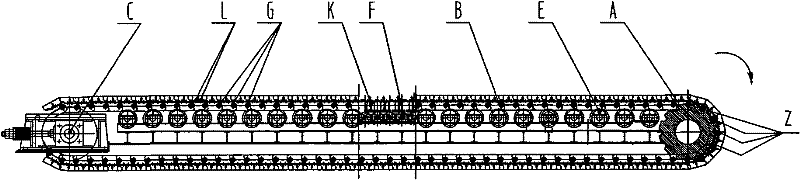

[0022] Such as image 3 , 4 , 5, a heavy-duty apron feeder that can achieve smooth transmission, mainly includes: drive shaft A and tension shaft C, a closed chain belt B wound on drive shaft A and tension shaft C, and a support The driving chain belt idler E and the load-bearing chain belt idler F of the chain belt.

[0023] The main function of the drive shaft A is to support the head of the chain belt and transmit power. Its structure is in the form of a sprocket, that is, the sprocket X meshing with the chain belt B is installed on the shaft. The sprocket moves the chain belt and ensures that the chain belt is on the shaft. Axial slippage and displacement will not occur.

[0024] The main function of the tensioning shaft C is to support and tension the tail of the chain belt to prevent the chain plate from sagging. Its characteristic is that the guide wheels W engaged with the chain belt B are set at both ends of the tensioning shaft C, and correspond to the sprocket X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com