Armored sludge pipe design method and sludge pipe thereof

A design method and armored pipe technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problem of shutdown, will be torn soon, once broken cannot be used, service life, product transportation cost gap and other issues, to achieve the effect of reliable technical scheme, novel design concept and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

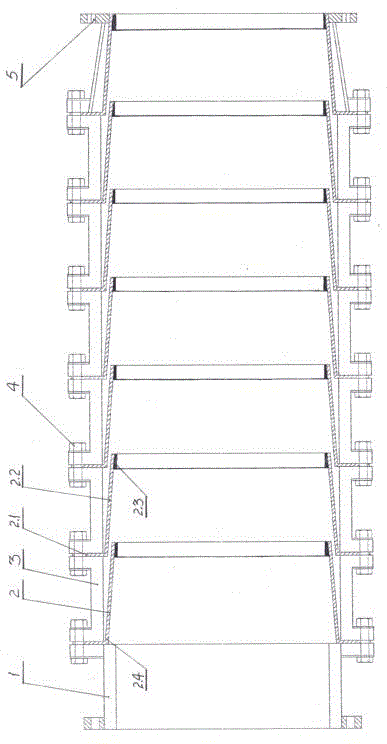

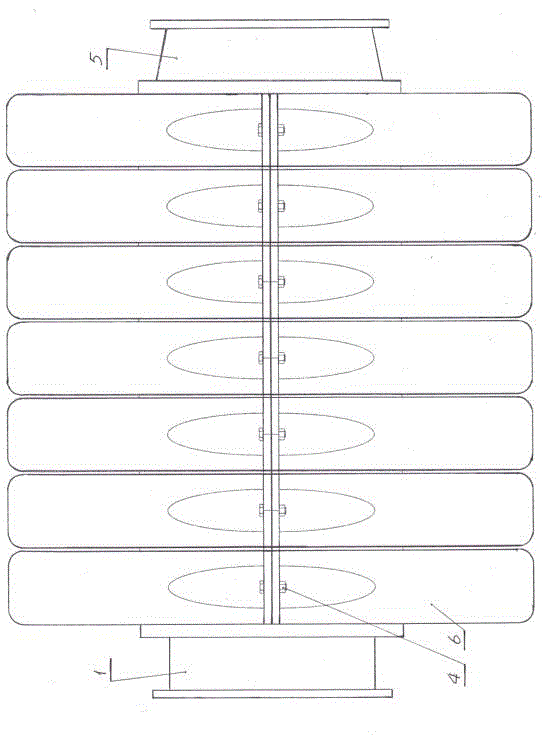

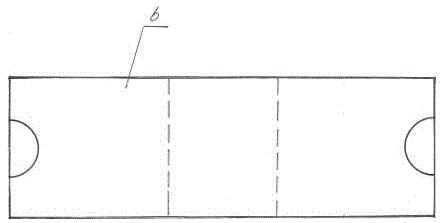

[0032] The design method of a kind of armored mud discharge pipe of embodiment 1 of the present invention, comprises the overall design to the armored pipe body and the flange plate at the two ends of pipe body and the specific design of each component, the armored pipe body described in it The design method is to meet the technical requirements of the armored mud discharge pipe with a curvature ≥ 35°, and the armored pipe unit is composed of multiple armored pipe tapered inner pipes and armored pipe outer pipes connected by bolts. , with flanges at both ends to form the design of the armored mud discharge pipe; the tapered inner pipe of the armored pipe body includes a circular disk, which extends to one side from the end of the inner diameter of the circular disk to the required discharge pipe. The tapered inner pipe of the mud pipe diameter has a working surface inside the outlet end of the tapered inner pipe, the working surface is parallel to the center line of the armored...

Embodiment 2

[0042] The design method of a kind of armored mud discharge pipe of the embodiment 2 of the present invention comprises the overall design and the specific design of each parts to the armored pipe body and the flange plate at both ends of the pipe body, the armored pipe body described in it The design method is to meet the technical requirements of the armored mud discharge pipe with a curvature ≥ 35°, and the armored pipe unit is composed of multiple armored pipe tapered inner pipes and armored pipe outer pipes connected by bolts. , with flanges at both ends to form the design of the armored mud discharge pipe; the tapered inner pipe of the armored pipe body includes a circular disk, which extends to one side from the end of the inner diameter of the circular disk to the required discharge pipe. The tapered inner pipe of the mud pipe diameter has a working surface inside the outlet end of the tapered inner pipe, the working surface is parallel to the center line of the armored...

Embodiment 3

[0054] The design method of a kind of armored mud discharge pipe of the embodiment 3 of the present invention comprises the overall design and the specific design of each component to the overall design of the armored pipe body and the flanges at the two ends of the pipe body, the armored pipe body described in it The design method is to meet the technical requirements of the armored mud discharge pipe with a curvature ≥ 35°, and the armored pipe unit is composed of multiple armored pipe tapered inner pipes and armored pipe outer pipes connected by bolts. , with flanges at both ends to form the design of the armored mud discharge pipe; the tapered inner pipe of the armored pipe body includes a circular disk, which extends to one side from the end of the inner diameter of the circular disk to the required discharge pipe. The tapered inner pipe of the mud pipe diameter has a working surface inside the outlet end of the tapered inner pipe, the working surface is parallel to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com