Self guiding type mechanical powder product finishing machine

A self-guided, powder technology, applied in the field of mechanical self-guided powder product finishing machine, can solve the problems of low finishing precision and complex structure of products, and achieve the effects of low manufacturing cost, advanced and reasonable structure, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

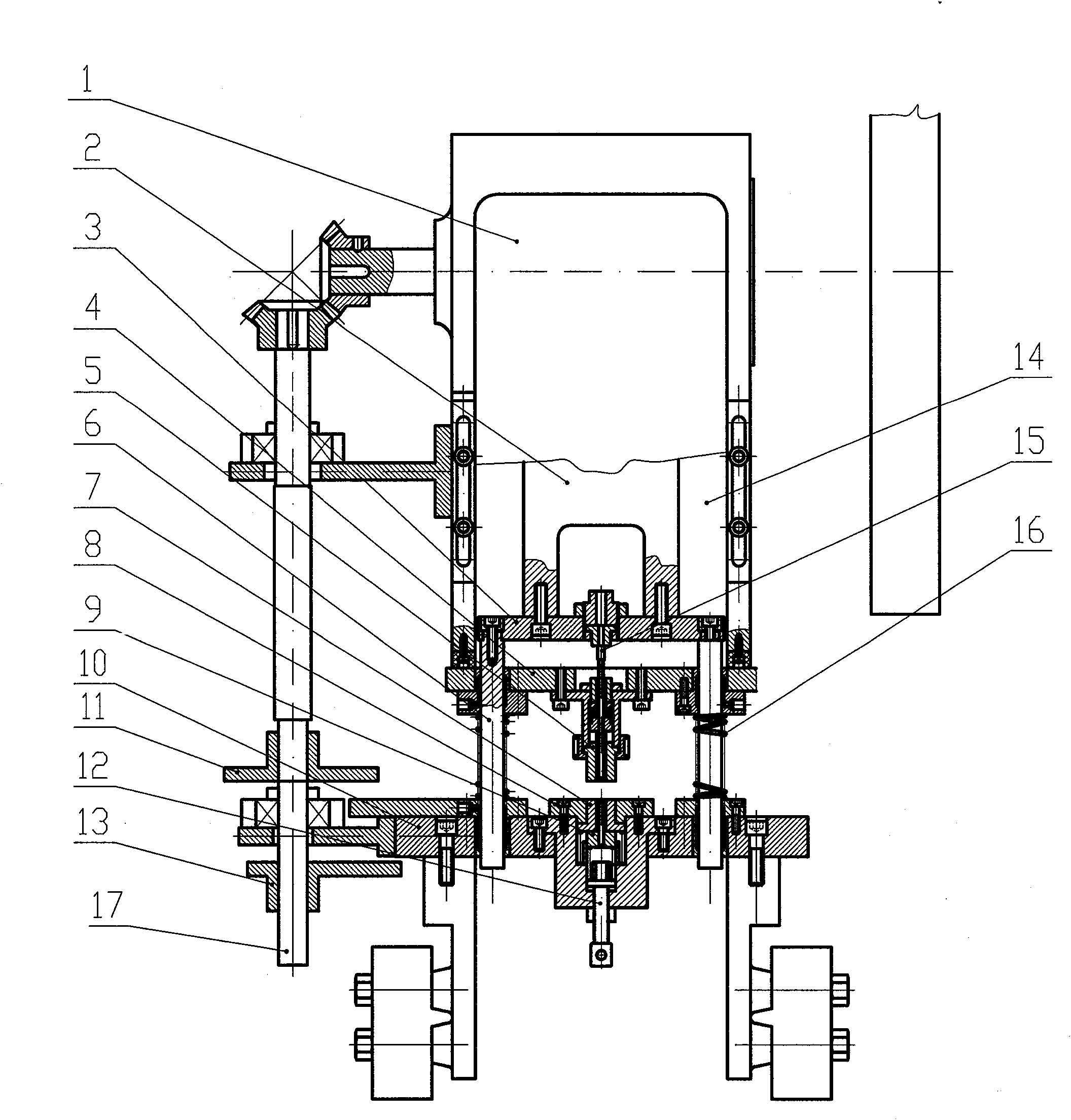

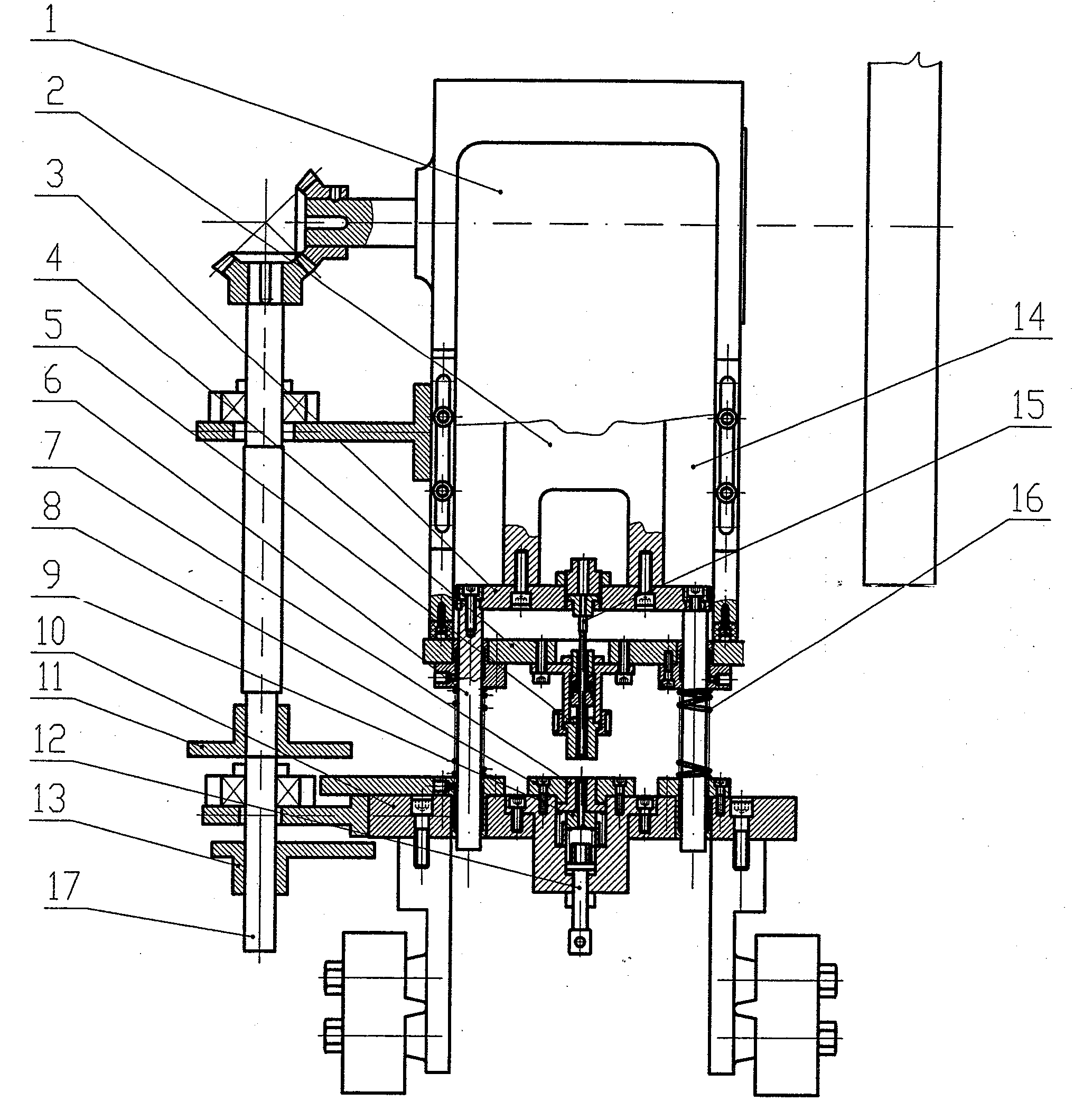

[0009] In conjunction with the accompanying drawings, a mechanical self-guiding powder product finishing machine of the present invention includes a frame 1, a motor, a flywheel, a crankshaft, an upper slider 2, an upper connecting plate 3, an upper punching fixing plate 4, a middle mold 10, Guide column 6, pressure regulating screw 12, transmission shaft, feeding mechanism, upper punch 5, pushing mechanism, female mold 7, female mold cover 8, lower punch 9, pushing cam 11, feeding cam 13, guide rail 14, mandrel 15. The return spring 16 of the upper punch fixed plate; the upper slider 2 reciprocates up and down through the guide rail 14 arranged on the frame 1 and driven by the crankshaft, and the upper connecting plate 3 is arranged at the bottom of the upper slider 2, and the upper punch The fixed plate 4 is arranged under the upper connecting plate 3, the middle mold 10 is arranged under the upper punch fixed plate 4, and is connected with the working table of the frame, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com