Dry wet-type drill box of anchor rod drill carriage

A bolter drilling rig, dry and wet technology, applied in the installation of bolts, drilling equipment, earthwork drilling and production, etc., can solve the problems of large drilling rig vibration, potential safety hazards, poor drilling quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

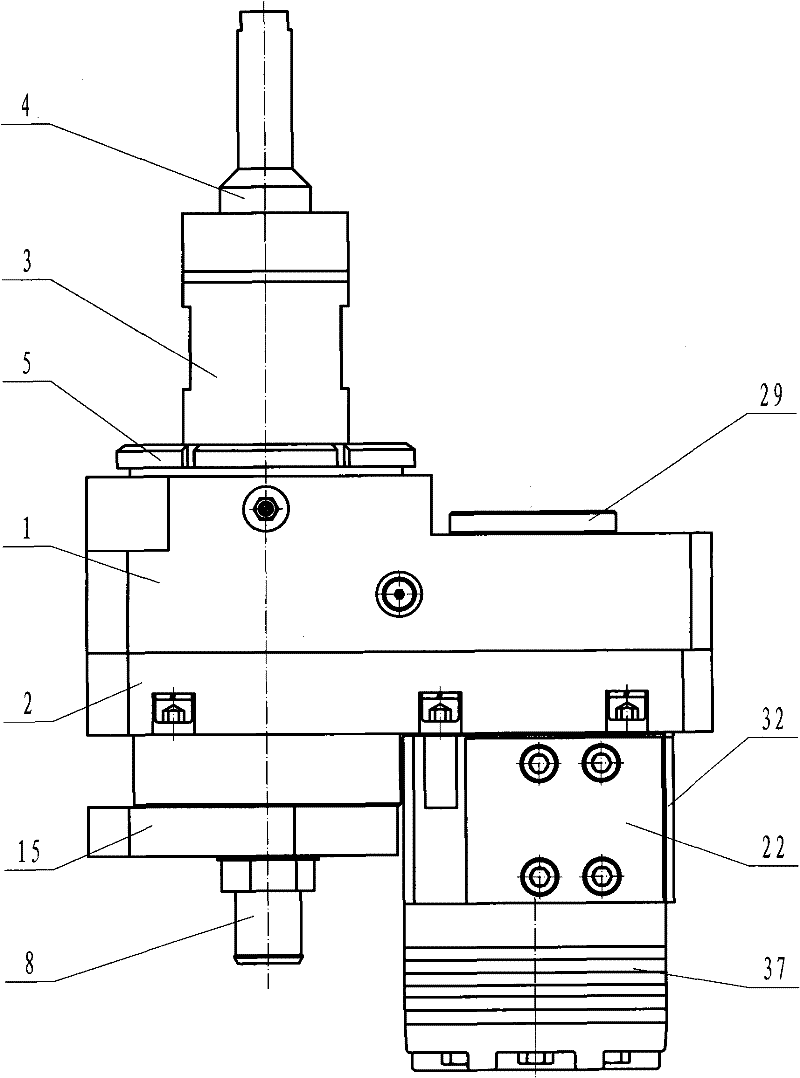

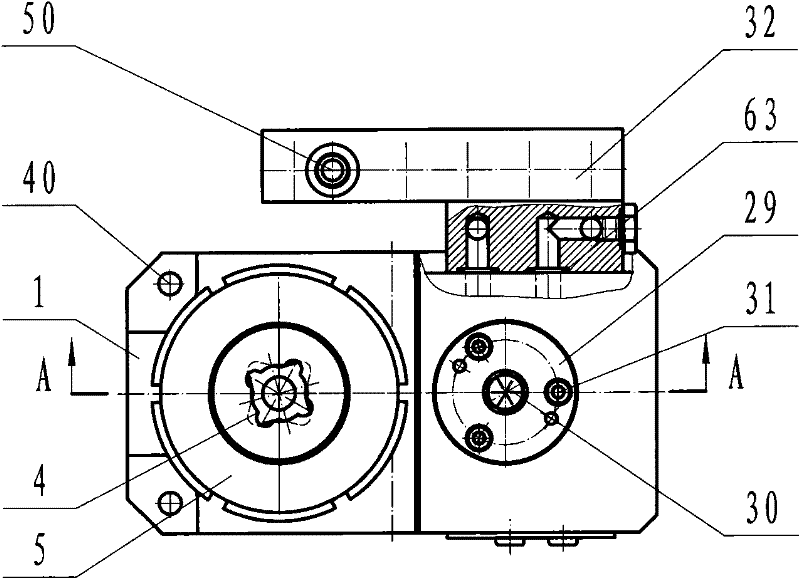

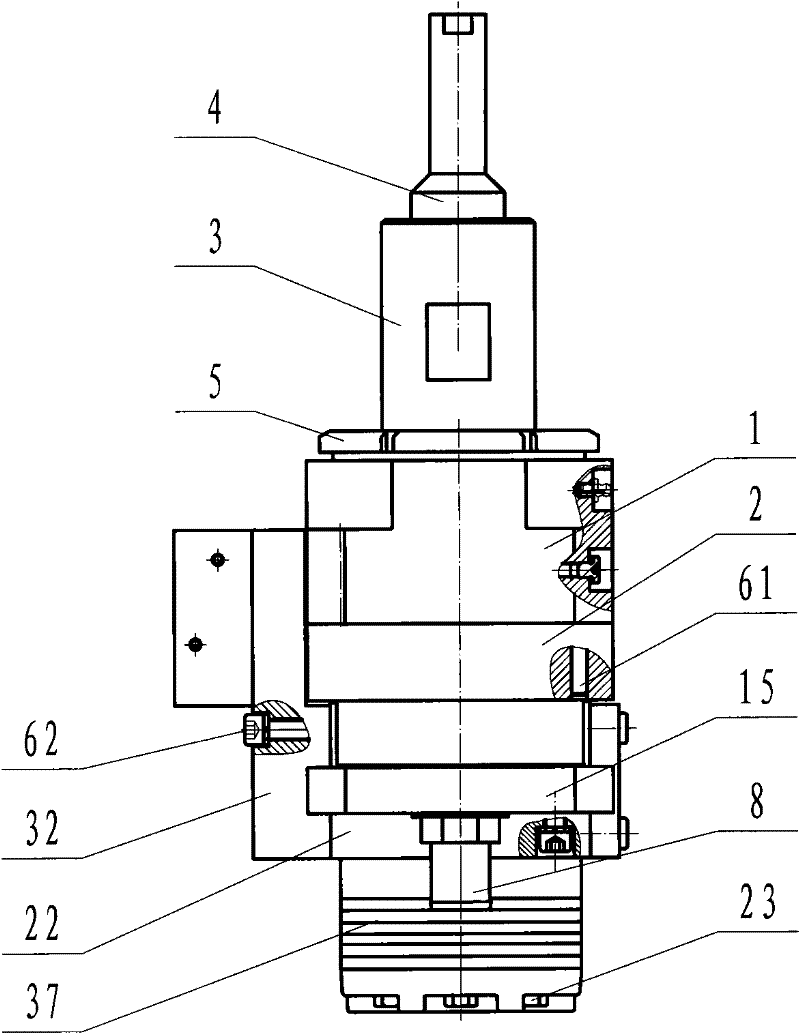

[0022] figure 1 , 2 , 3, and 4 show the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0023] The upper and lower boxes, lower end cover, hydraulic motor connection block, liquid distribution plate, hydraulic motor, and upper end cover must be strictly sealed to prevent oil leakage.

[0024] The upper part is the drill pipe, the lower part is the water and air pipe joint, and the right part is driven by the hydraulic motor, forming a fully sealed structure, which can prevent dust and water mist, and can be drilled under dry dust removal and sprayed. Wet drilling.

[0025] The gear of the hydraulic motor shaft and the gear of the transmission shaft are in a 1:1 transmission connection.

[0026] Figure 5 , 6 As shown, it is the structural diagram of the liquid distribution plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com