Guild rail type free float drain valve

A guide rail type, floating ball technology, applied in the direction of steam traps, mechanical equipment, etc., can solve the problems of poor stability and other problems, and achieve the effects of good sealing performance, obvious switching action, and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

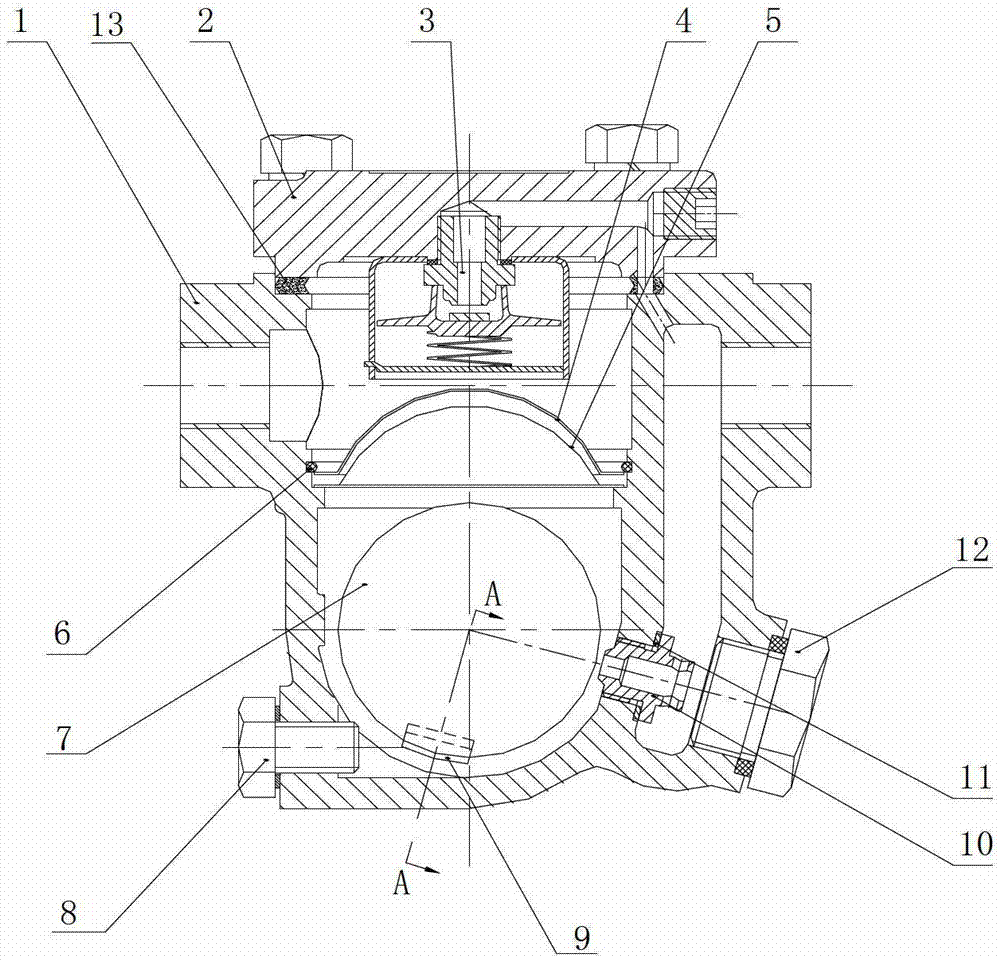

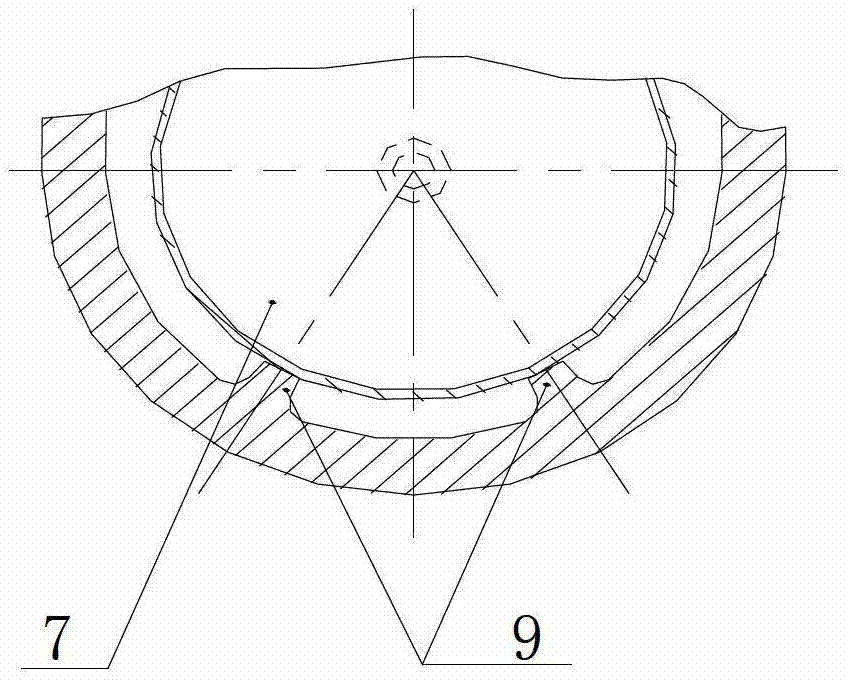

[0016] see figure 1 with 2 , the embodiment of the present invention is provided with a valve body 1, a valve cover 2, an air exhaust device 3, a filter screen 4, a partition cover 5, a retaining spring 6, a floating ball 7, a sewage bolt 8, a guide rail 9, a main valve seat 10, a main valve Seat gasket 11, outer plug 12 and winding pad 13.

[0017] The bonnet 2 is installed on the upper end of the valve body 1, and a winding pad 13 is installed between the valve body 1 and the bonnet 2 and is tightly connected with bolts and nuts; The floating ball 7 is loaded into the inner cavity of the valve body 1; the partition cover 5 and the filter screen 4 are respectively installed on the inner cavity boss of the valve body 1; the circlip 6 is pressed on the filter screen 4 and loaded into In the groove of the circlip 6; the blowdown bolt 8 is inserted into the winding pad and installed in the blowdown threaded hole at the lower end of the valve body 1; The axis of 9 is coaxial wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com