Garbage sweeper

A technology for sweeping vehicles and garbage, applied in the field of garbage sweeping vehicles, can solve the problems of easy damage of rolling brushes, troublesome maintenance and high cost, and achieve the effects of reasonable and advanced structure, good cleaning effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

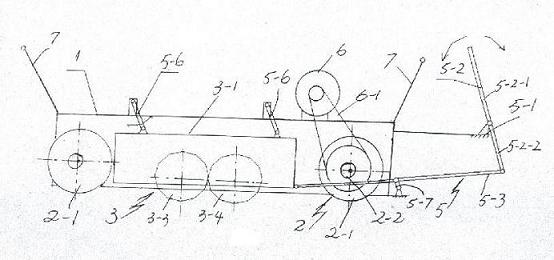

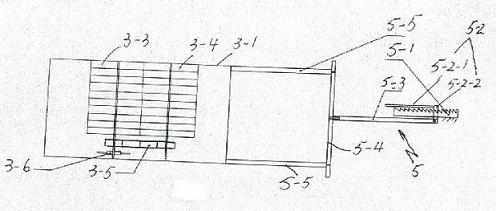

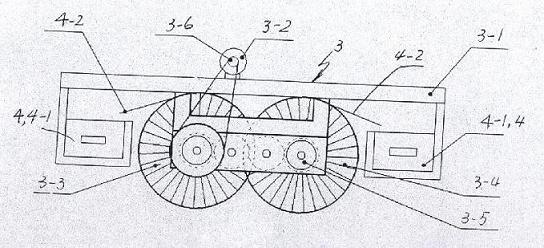

[0027] For the second specific implementation mode, please refer to the attached Figure 1~3 .

[0028] A garbage cleaning vehicle comprises a vehicle frame 1, a rotatable walking wheel assembly 2 connected to the vehicle frame 1, a cleaning device 3 connected to the vehicle frame 1 and a garbage storage box assembly 4, and it:

[0029] The cleaning device 3 includes a mounting frame 3-1, a cleaning motor 3-2 fixed on the mounting frame 3-1 and electrically connected to the vehicle power supply through an electric controller, a first rolling brush 3-3, and a second rolling brush 3-4; the outer bristles of the first rolling brush 3-3 and the second rolling brush 3-4 intersect and are respectively connected to the mounting frame 3-1 in rotation; the first rolling brush 3-3 and the second rolling brush The brush 3-4 is connected through the transmission of the first transmission assembly 3-5, and the rotation direction of the two is opposite; the cleaning motor 3-2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com