Flexible thin-film solar photoelectric cell and large-scale continuous automatic production method thereof

A flexible film and production method technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., to achieve the effects of high conversion rate, lower temperature rise, and elimination of waste water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the utility model will be described in detail below in conjunction with the accompanying drawings, so that the advantages and characteristics of the utility model can be more easily understood by those skilled in the art, so that the protection scope of the utility model can be defined more clearly .

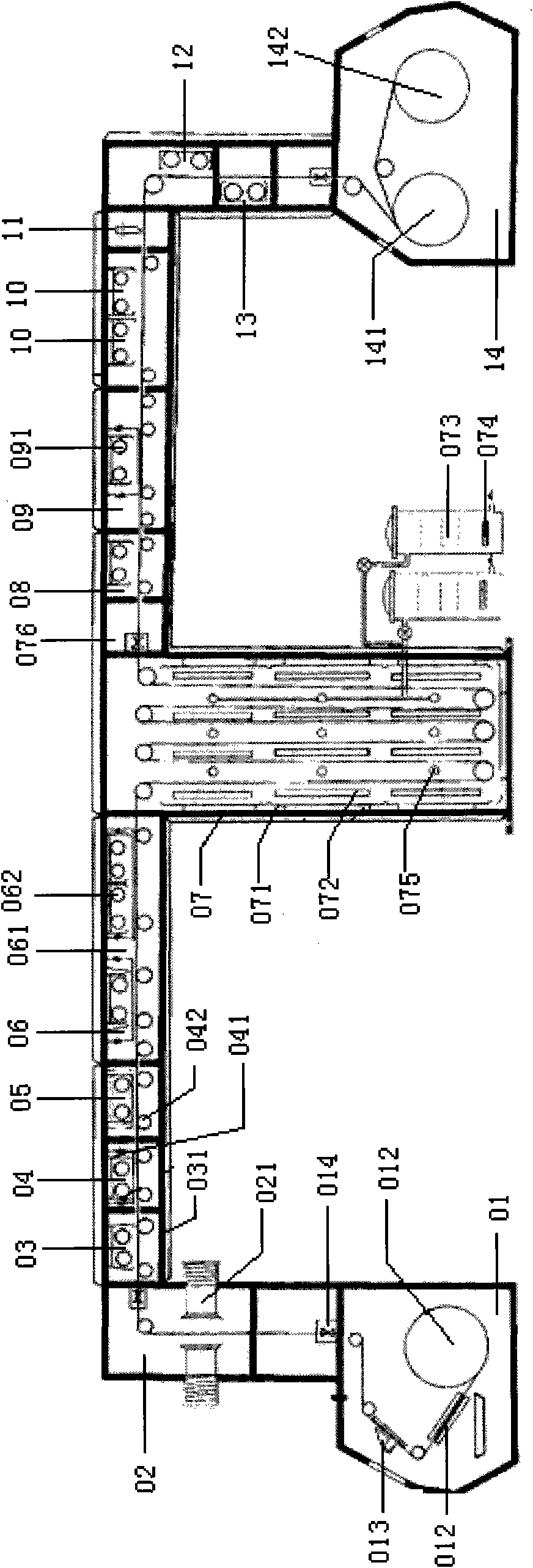

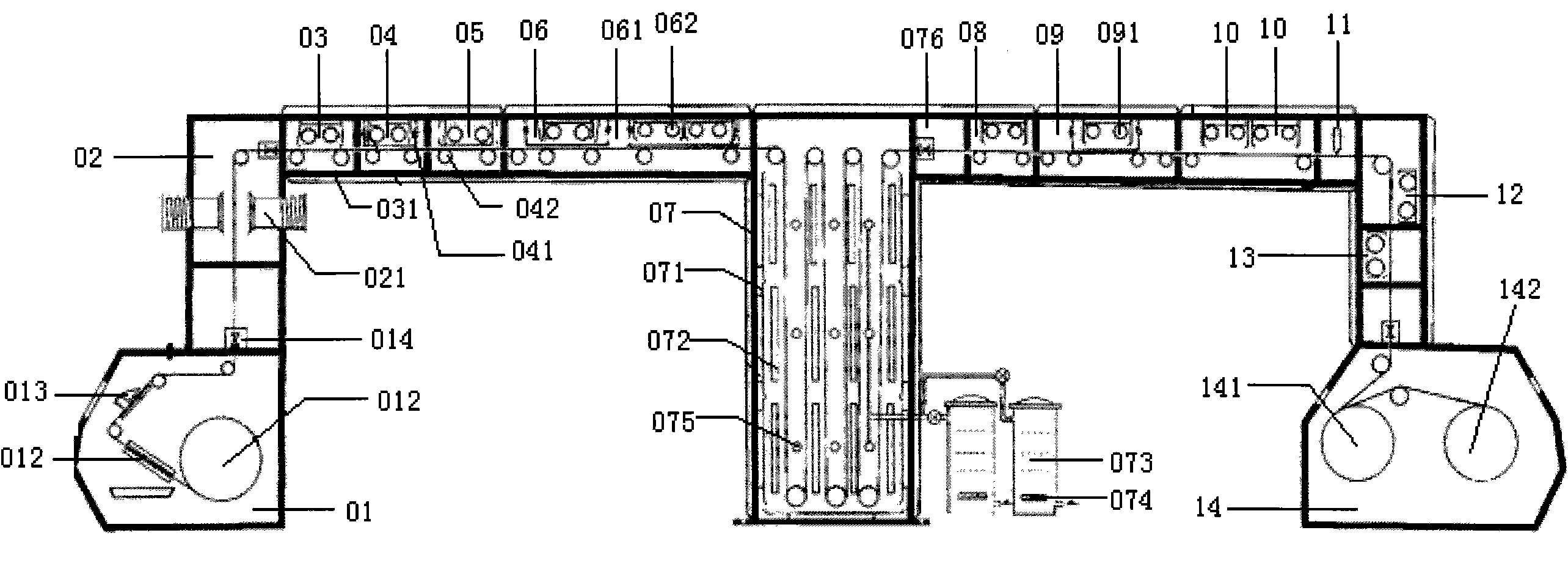

[0045] Such as figure 1The flow chart of a continuous automatic production equipment for flexible thin-film solar photovoltaic cells is shown. It can be seen from the figure that it is a continuous and complete vacuum production system. The base material selected in this embodiment is copper foil, and the thickness of the base material is 0.05 ~0.1mm, the base material starts from the unwinding roll 011 in the feeding chamber 01, advances sequentially through the guide rolls, and its advancing speed is 0.8m / min, passes through the dust collector 012 to remove dust, welds with the welder 013, and is separated by a slit The valve 014 enters the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com