Flame-retardant modified bitumen waterproof coiled material coating material and flame-retardant self-adhesive bitumen waterproof coiled material and preparation method thereof

A kind of asphalt waterproof membrane and modified asphalt technology, applied in chemical instruments and methods, roofs using flexible materials, building insulation materials, etc., can solve the problems of poor adhesion and heat resistance, thick flame-retardant membranes, and energy consumption Large and other problems, to achieve the effect of high bonding strength, good heat resistance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

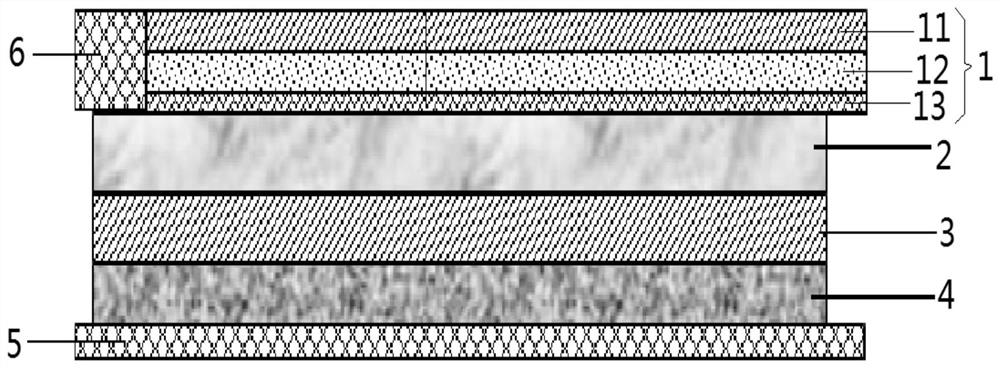

Image

Examples

preparation example Construction

[0064] In the embodiment of the present invention, the preparation method of the flame-retardant modified asphalt layer coating material comprises: mixing low-grade petroleum asphalt, high-grade petroleum asphalt, polymer modifiers, tackifiers, functional additives, and fillers at 150 Mix and stir at 3000 rpm for 30 minutes at a temperature of ℃, control the temperature at 175 ℃, shear and mix for 5.5 hours, then cool down to 150 ℃, add a flame retardant and stir for 30 minutes to obtain the flame-retardant modified asphalt layer coating material .

[0065] In the embodiment of the present invention, the preparation method of flame-retardant self-adhesive asphalt layer coating material includes: low-grade petroleum asphalt, high-grade petroleum asphalt, polymer modifier, tackifier, functional auxiliary agent, filler, retarder For the fuel, mix and stir at 150°C and 3000rpm for 30 minutes, gradually increase the temperature, control the temperature to 175°C, and shear and mix f...

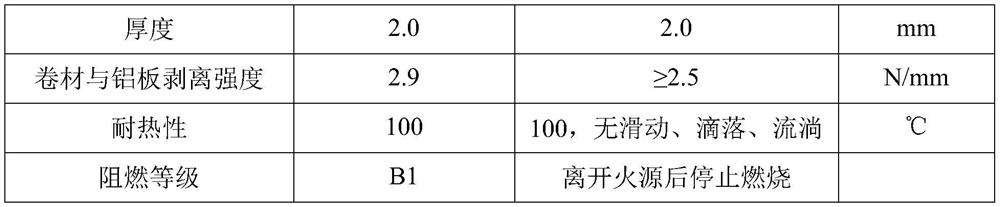

Embodiment 1

[0075] In this embodiment, the raw material composition of the flame-retardant modified asphalt layer is:

[0076] 105 parts by weight of 50# petroleum asphalt, 25 parts by weight of 180# petroleum asphalt, 26 parts by weight of polymer modifier (15 parts by weight of SEBS, 5 parts by weight of SSBR, 6 parts by weight of APAO), 5-8 parts by weight of tackifier (C5 4 parts by weight of petroleum resin, 2 parts by weight of C9 petroleum resin, 2 parts by weight of polyisobutylene), 8 parts by weight of flame retardant (4 parts by weight of aluminum hydroxide, 4 parts by weight of phosphoric acid ester), 4 parts by weight of functional additive (anti-aging Agent BASF IRGAFOS 168, 2 parts by weight, antioxidant BASF IRGANOX 1010, 2 parts by weight), 20 parts by weight of 400 mesh light calcium carbonate.

[0077] In the present embodiment, the raw material composition of flame-retardant self-adhesive asphalt layer is:

[0078] 130 parts by weight of 50# petroleum asphalt, 40 part...

Embodiment 2

[0084] In this embodiment, the raw material composition of the flame-retardant modified asphalt layer is:

[0085] 120 parts by weight of 50# petroleum asphalt, 20 parts by weight of 180# petroleum asphalt, 23 parts by weight of polymer modifier (8 parts by weight of SBS, 9 parts by weight of SSBR, 5 parts by weight of APAO), 5-8 parts by weight of tackifier ( 3 parts by weight of C5 petroleum resin, 3 parts by weight of C9 petroleum resin, 2 parts by weight of polyisobutylene), 9 parts by weight of flame retardant (3 parts by weight of aluminum hydroxide, 6 parts by weight of phosphoric acid ester), 4 parts by weight of functional auxiliary agent (anti- Aging agent BASF IRGAFOS 168, 2 parts by weight, light stabilizer TINUVIN 622LD, 2 parts by weight), 400 mesh light calcium carbonate 20 parts by weight.

[0086] In the present embodiment, the raw material composition of flame-retardant self-adhesive asphalt layer is:

[0087] 120 parts by weight of 50# petroleum asphalt, 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com