Brake with cooling in driving axle of battery forklift

A technology of internal brakes and drive axles, used in cooling brakes, brakes, hydraulic brake transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

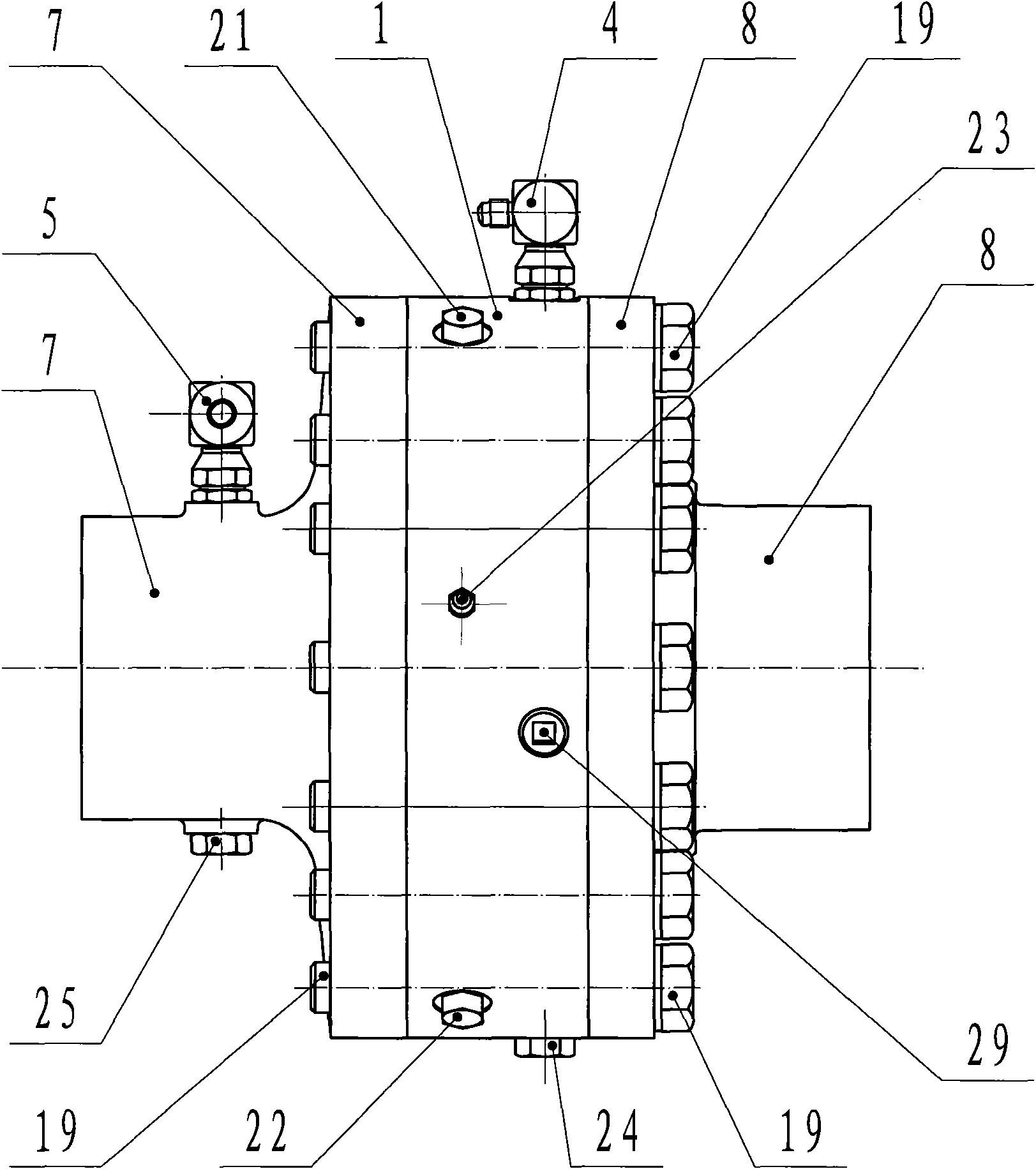

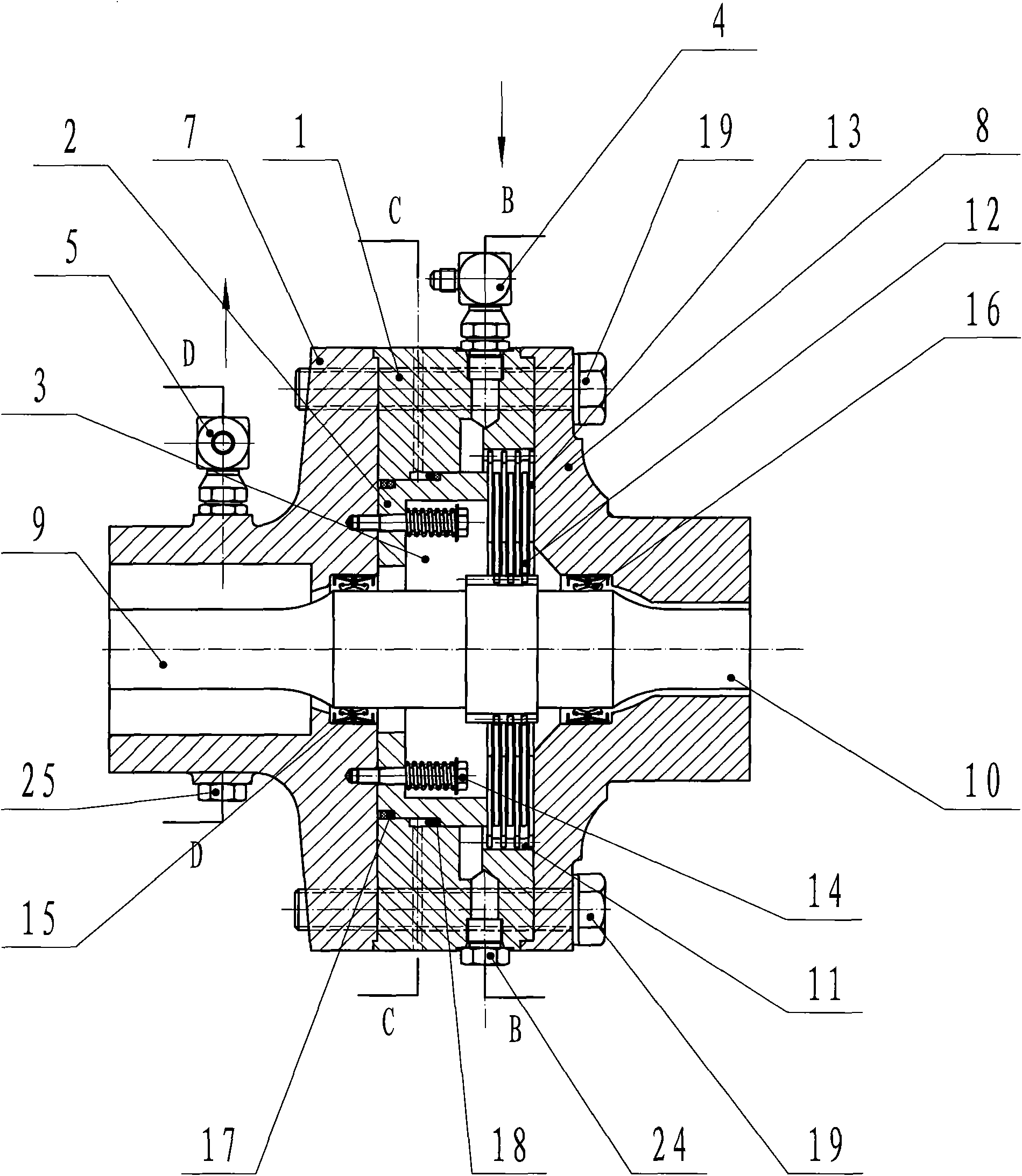

[0021] figure 1 , 2 Shown is the overall structure diagram, and the connection relationship of each part must be correct and the installation should be firm.

[0022] The brake is composed of four brake springs, four static friction plates, and three dynamic friction plates to complete wet braking under the action of brake oil in and out.

[0023] Cooling is carried out by the cooling oil inlet and outlet valves, oil inlet and outlet pipes, and piston cavity for external circulation of cooling oil.

[0024] All oil pipes, oil passages and oil chambers must be clean and unimpeded.

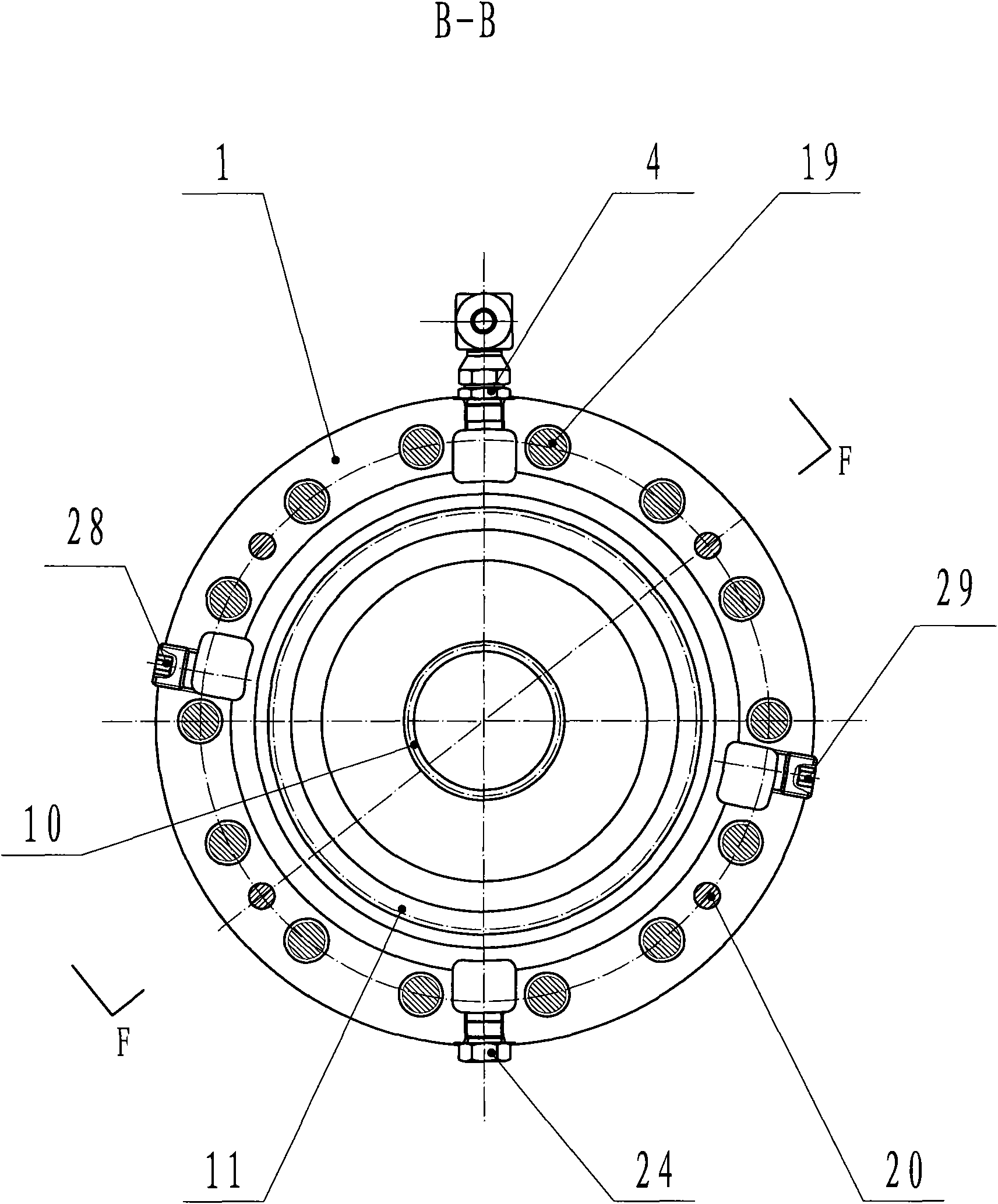

[0025] image 3 , 4 , 5, 6, and 7 show the positions of cooling oil inlet and outlet valves, brake oil inlet and outlet ports, lubricating oil inlet and outlet ports, vent plugs, screw plugs, screws and spline sleeves, and spline shafts. The positions of each part are arranged reasonably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com