Automatic braiding machine

A marshalling machine and automatic technology, applied in the direction of ceramic molding machines, conveyor objects, unloading devices, etc., can solve the problems of only marshalling, single function, low accuracy, etc., to achieve advanced and reasonable equipment structure, solve unstable, Affordable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

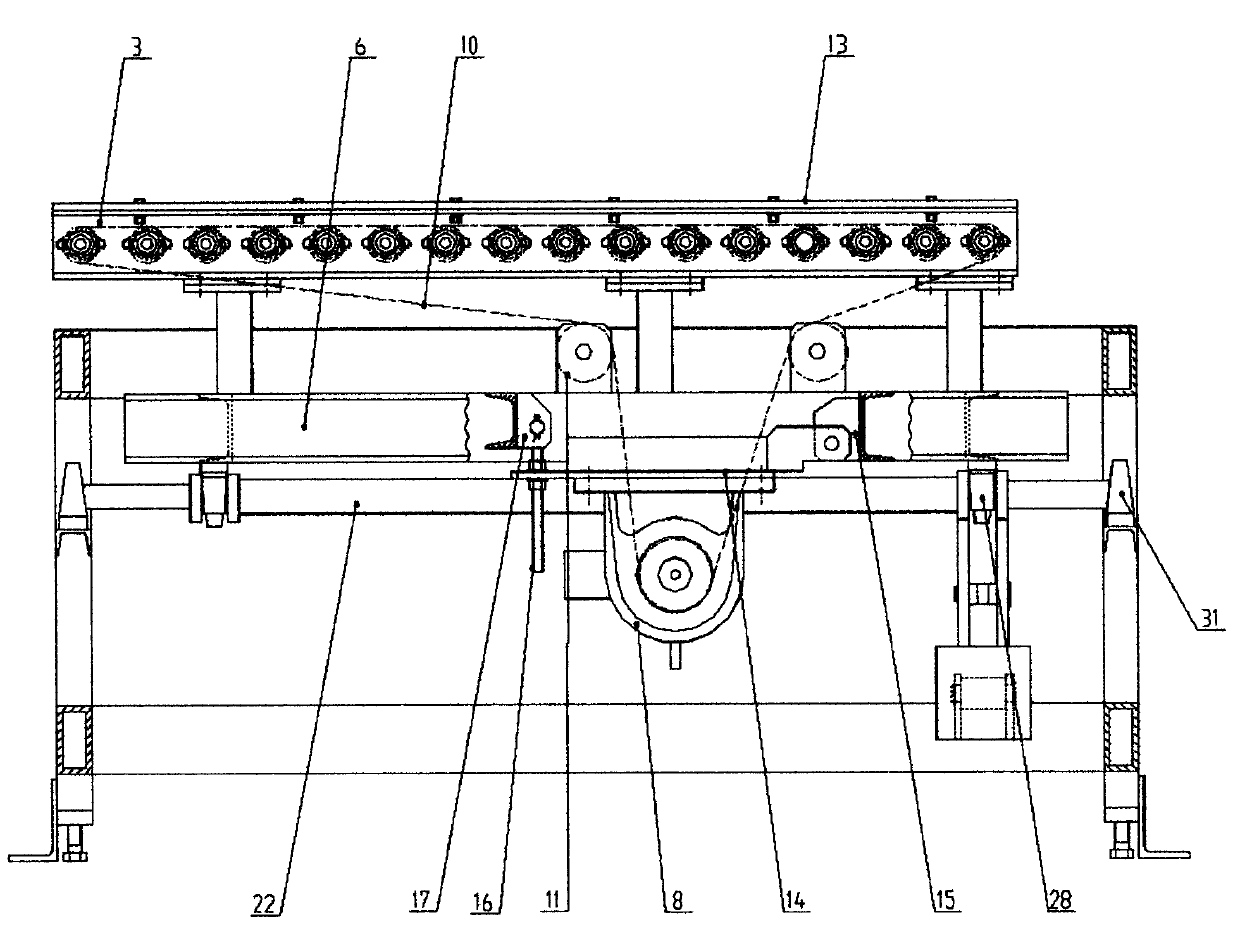

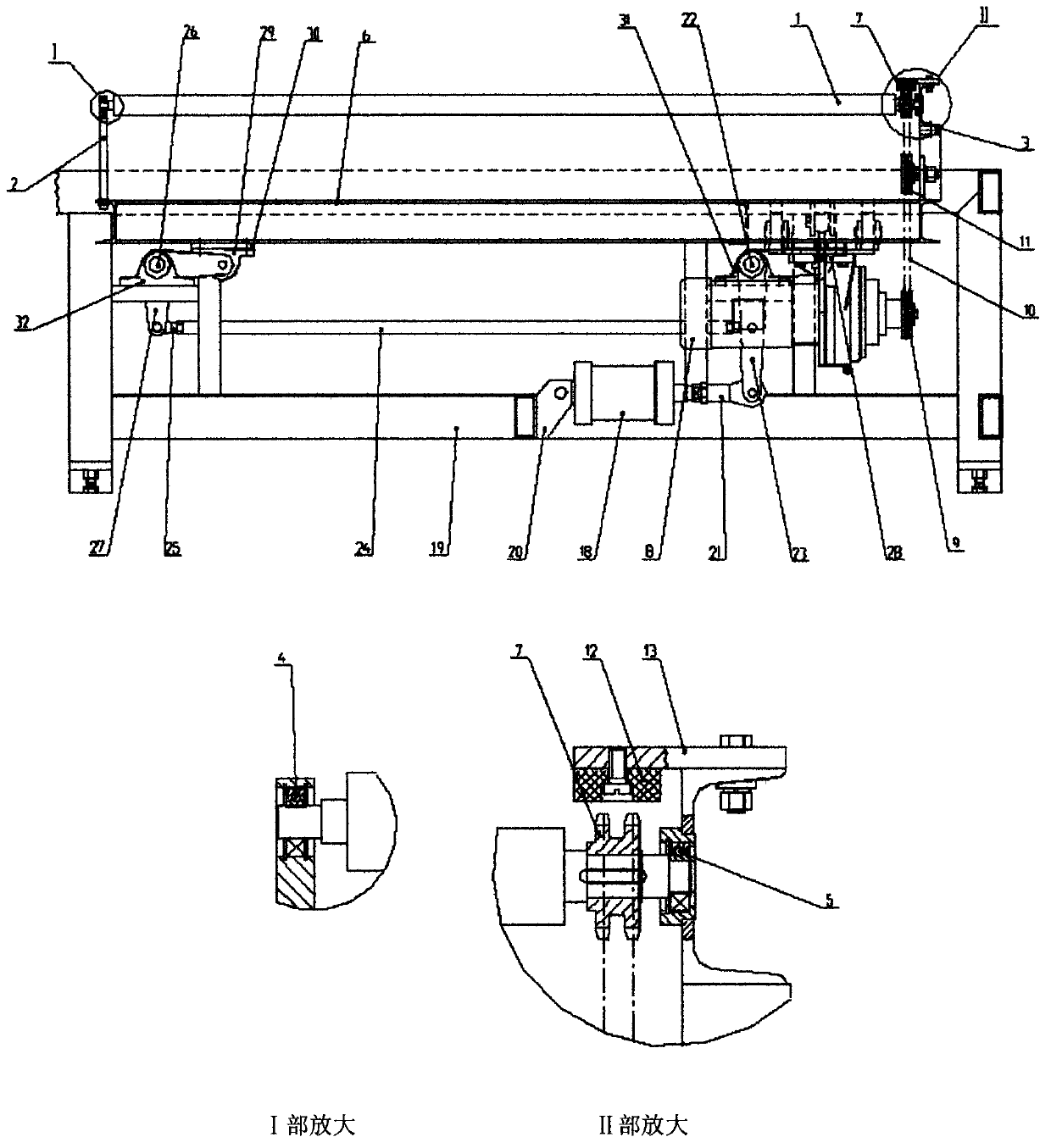

[0030] The automatic marshalling machine of the present invention is mainly composed of a billet feeding idler mechanism, an overturning mechanism, a transverse seam dividing mechanism, a longitudinal seam dividing mechanism, and a roller chain conveying mechanism with a cover.

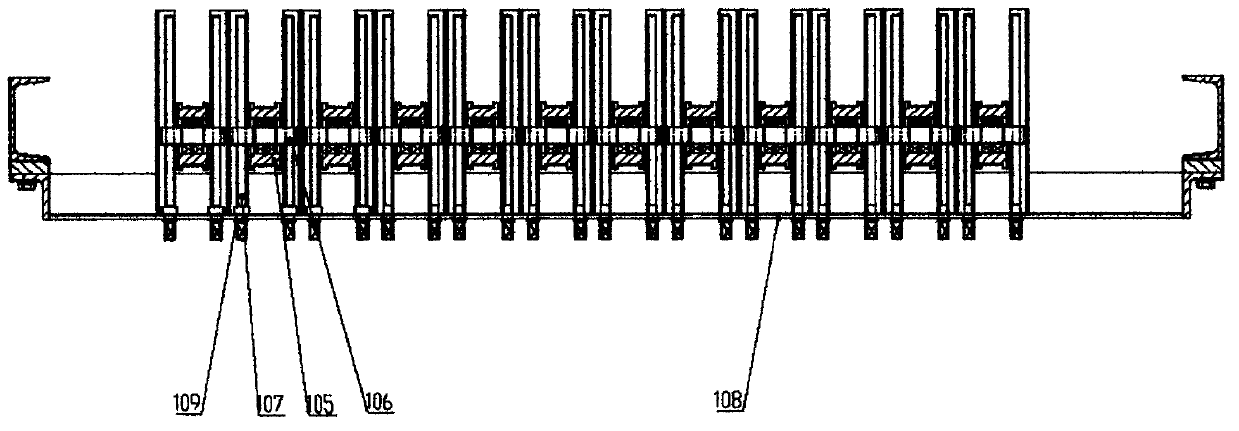

[0031] The billet feeding idler mechanism is mainly composed of a geared motor, a motor base, a support plate, a channel steel frame, an ear plate, an idler frame, a screw, a driving sprocket, an idler, a small sprocket, a double-row roller chain, and a guide sprocket , polystyrene pressure plate, lifting cylinder, joint bearing, crankshaft, connecting rod, blank plate assembly, bearing seat plate, and adjusting connecting rod. The two ends of the roller 1 are respectively supported on the bearing 4 in the hole of the support plate 2 and the bearing 5 in the hole of the channel steel frame 3. The support plate 2 and the channel steel frame 3 are fixed on the roller frame 6 through bolt connection. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com