Three-dimensional grid core material woven fabric

A three-dimensional grid, woven fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of difficult tamping operation, poor containment performance of foamed cement and gypsum, inconvenient use on site, etc., to improve the preparation efficiency. , The effect of saving process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through the description of specific embodiments in conjunction with the accompanying drawings.

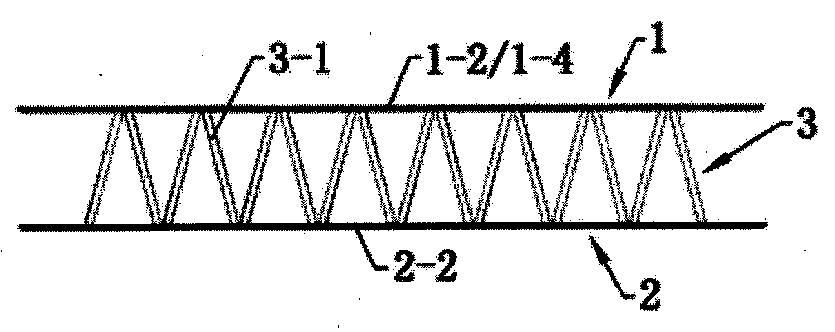

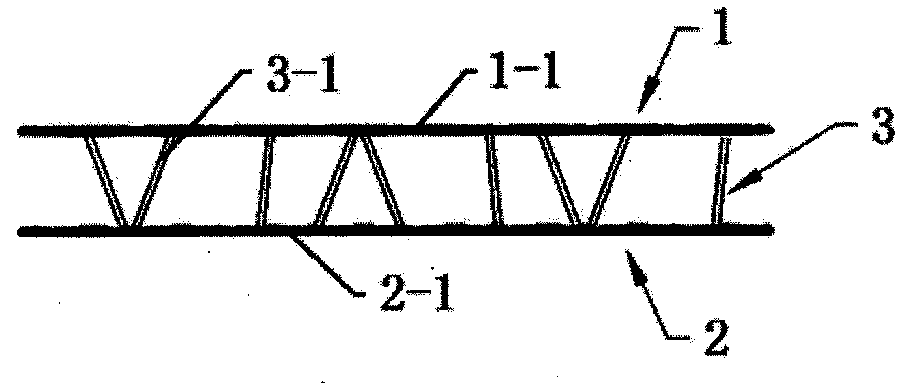

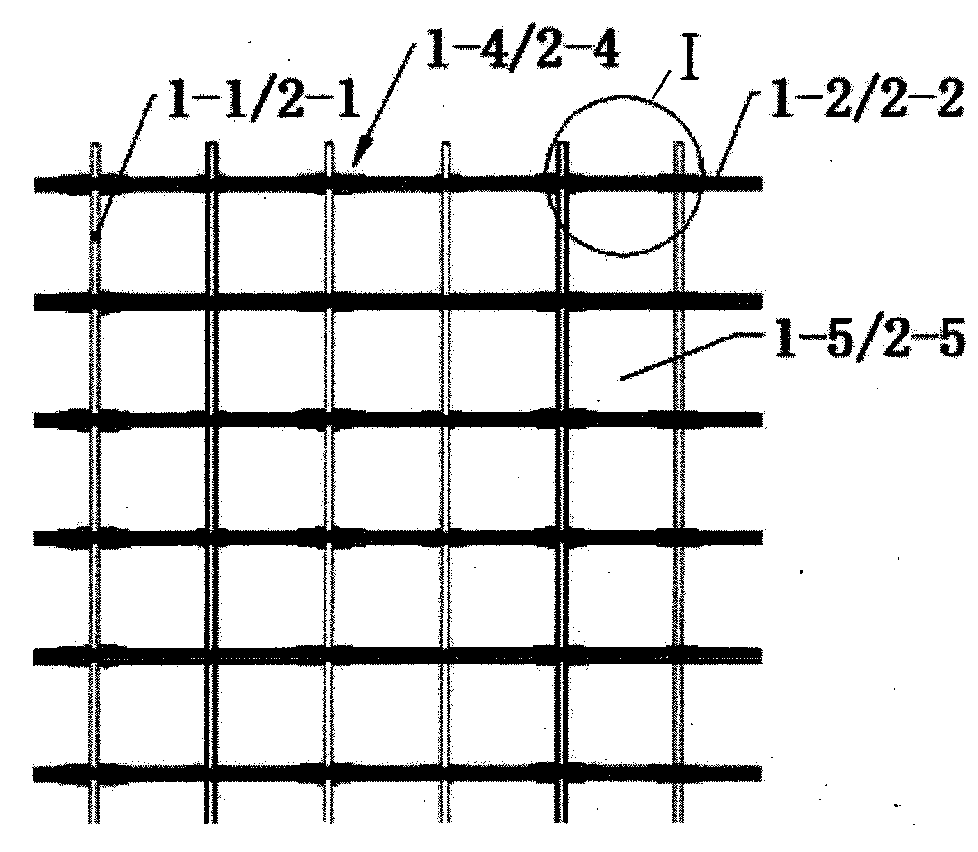

[0026] One of the specific implementation modes, as attached Figure 1~5 shown.

[0027] A three-dimensional grid core material woven fabric, a first surface layer fabric 1 and a second surface layer fabric 2 woven by inorganic non-metallic material weft and warp, and used to connect the first surface layer fabric 1 and the second surface layer fabric The core layer 3 of the facing fabric 2 consists of:

[0028] a. The first surface layer fabric 1 is interwoven with low weft density weft yarns 1-1 and warp yarns 1-2 in a plain weave structure, and the adjacent warp yarns 1-3 are twisted to each other A plurality of warp yarns 1-2 in the section are respectively bundled into ply warp yarns 1-4, thereby forming a first surface layer fabric with a continuous mesh 1-5 grid-like structure with a thickness in the range of 2-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com