LED optical strip and method of manufacturing the same

A technology for light-emitting diodes and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, and electric-solid-state devices, etc., can solve the problems of increased cost, increased weight and size of light-emitting diode light bars, complicated manufacturing process procedures, etc. The effect of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

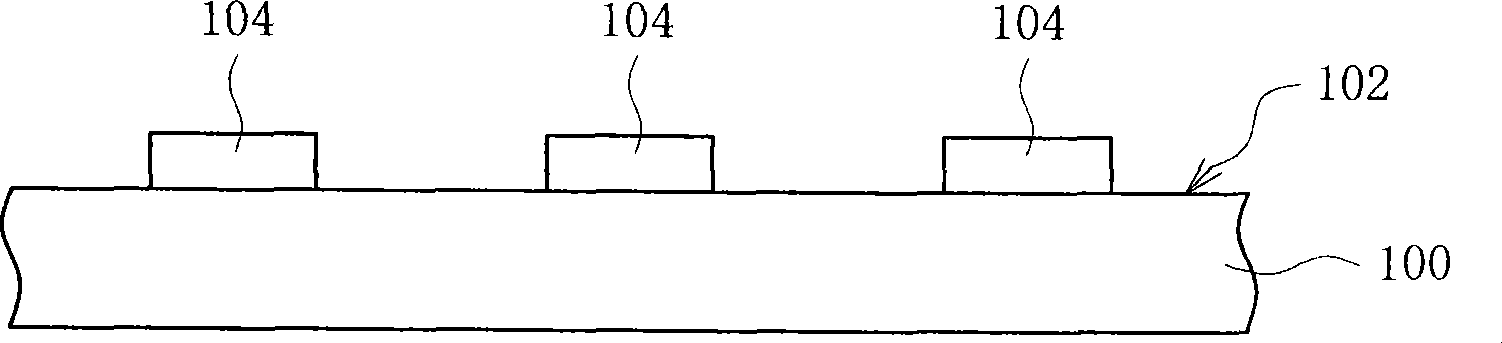

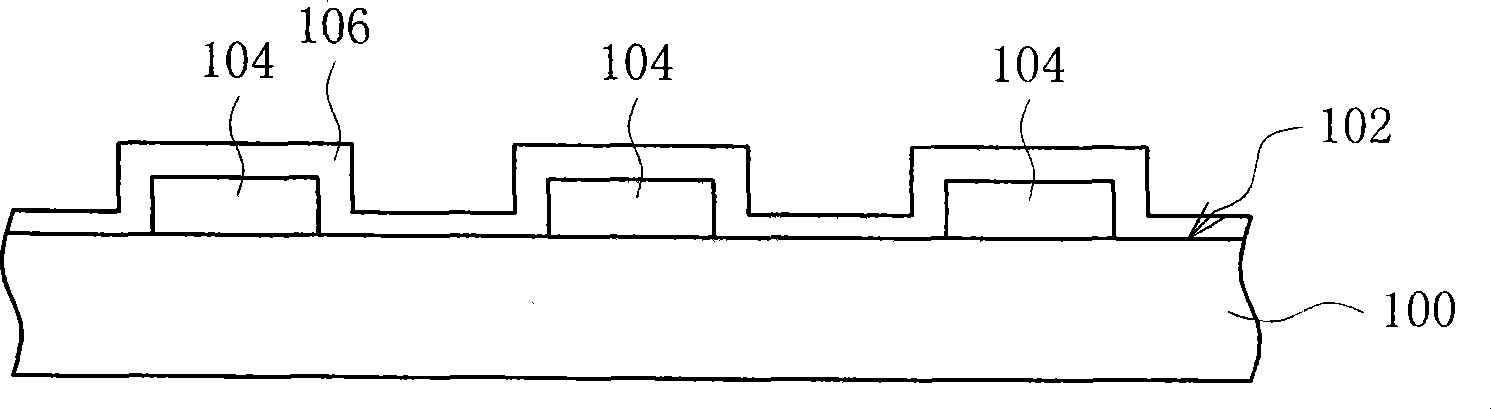

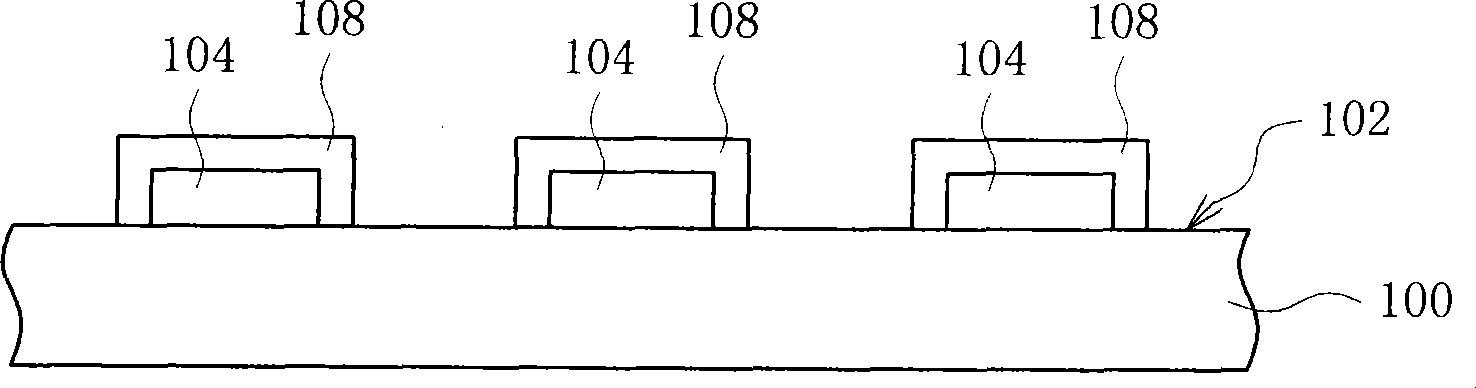

[0021] The invention discloses a light emitting diode light bar and a manufacturing method thereof. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 1 to Figure 6 .

[0022] Please refer to Figure 1 to Figure 6 , which is a schematic diagram of the manufacturing process of a light emitting diode light strip according to a preferred embodiment of the present invention, wherein Figure 1 to Figure 4 is a cross-sectional diagram, Figure 5 and Figure 6 It is a schematic diagram from above. In an exemplary embodiment, making a Figure 6 In the case of the LED light bar 112 shown, a circuit board 100 may be provided first for chips to be disposed thereon, wherein the circuit board 100 is preferably pre-set with a required circuit layout. In one embodiment, the circuit board 100 can be a common printed circuit board. Next, using, for example, a bonding method, a plurality of LED chips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com