Automatic-batching pipe inserting machine for doffing of spinning frame

A spinning frame and intubation machine technology, applied in textiles and papermaking, etc., can solve the problems of high equipment investment, increased labor costs, low intubation efficiency, etc., and achieve a high degree of automation, advanced and reasonable structure, and accurate intubation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings in combination with the description of specific embodiments.

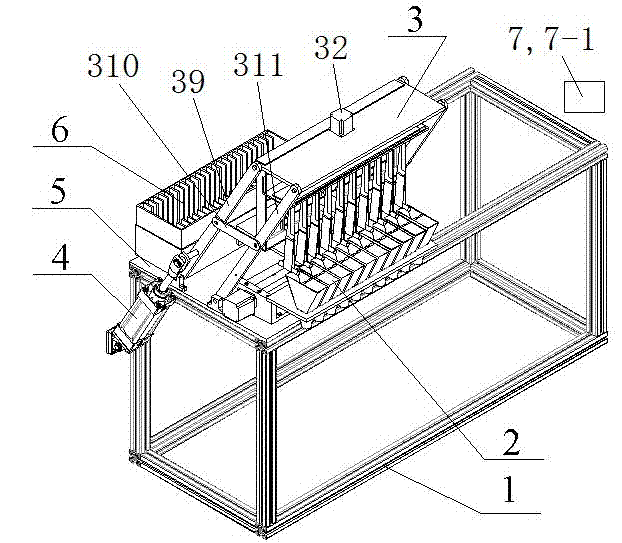

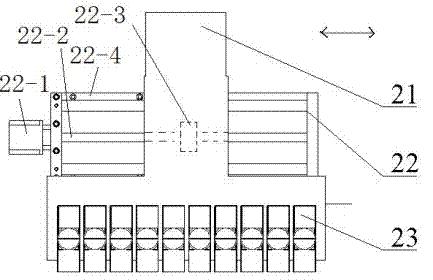

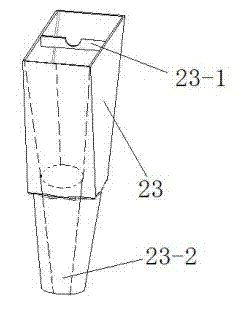

[0031] For one of the specific implementation methods, please refer to the attached Figure 1~6 ,

[0032] An automatic batch inserting machine for spinning frame doffing, comprising:

[0033] Electric control device 7;

[0034] Frame 1; the frame 1 is matched with the walking doffer, and is relatively positioned with the spinning frame through the electric control device of the walking doffer; the electric control device 7 is arranged on the frame 1;

[0035] Bobbin box 6; the longitudinal inner width K1 of the bobbin box 6 is loosely matched with the length of the bobbin; several compartment boards 6-1 are separately arranged at equal intervals on the two lateral inner sides of the bobbin box 6, thereby forming several bobbin bins 6-2, the inside width K2 of the bobbin warehouse 6-2 is loosely matched with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com