Multi-gear multivariant movable axis type semi-automatic control speed changing box

A technology with degrees of freedom and multiple gears, applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems of high heating empty power consumption, high working noise, complex structure, etc., to achieve advanced and reasonable structure, low empty power consumption, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

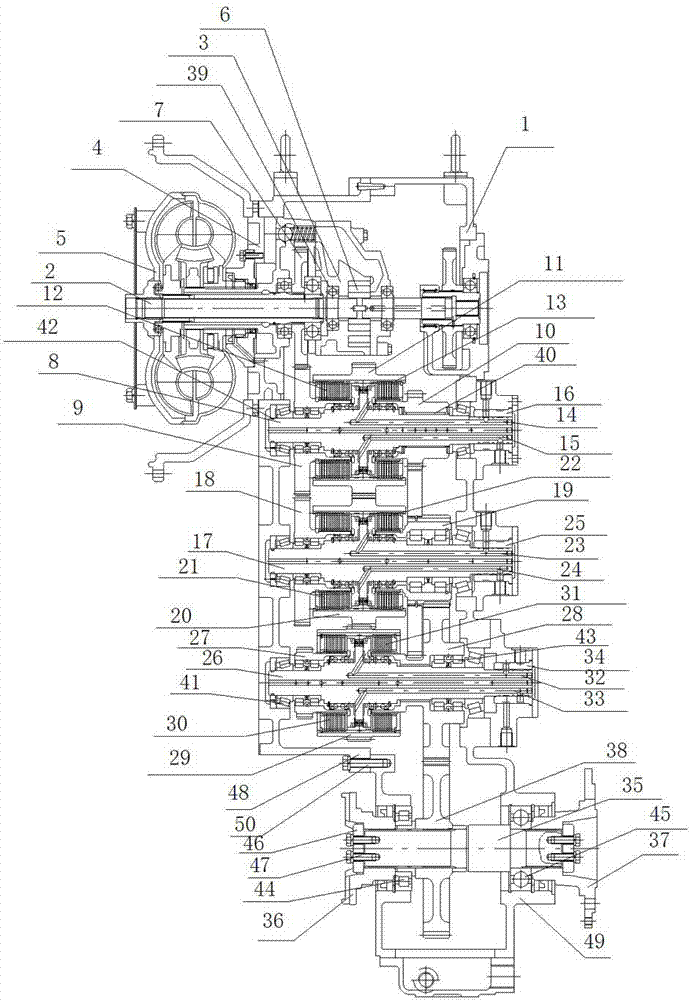

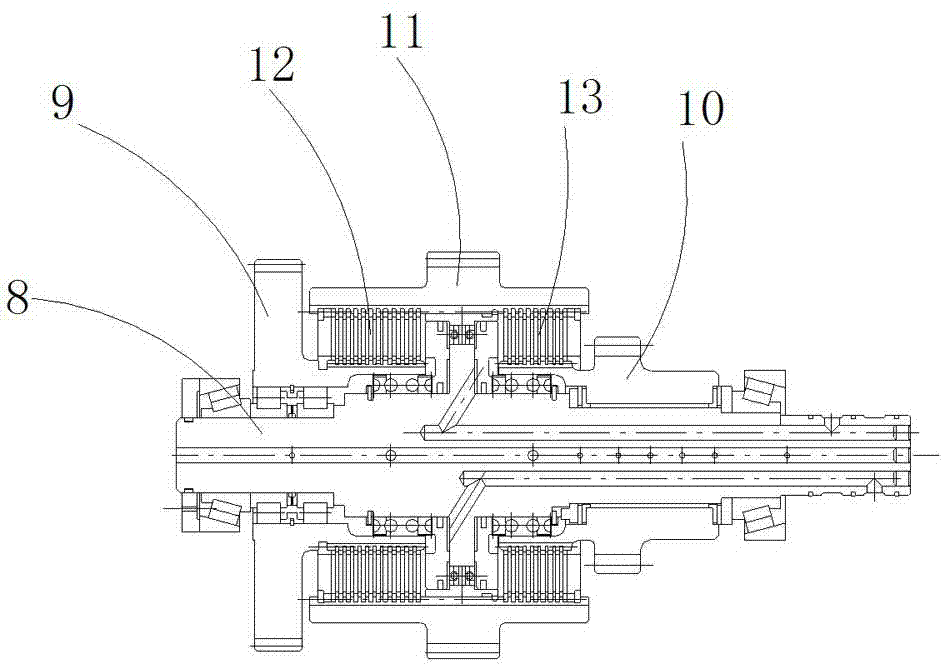

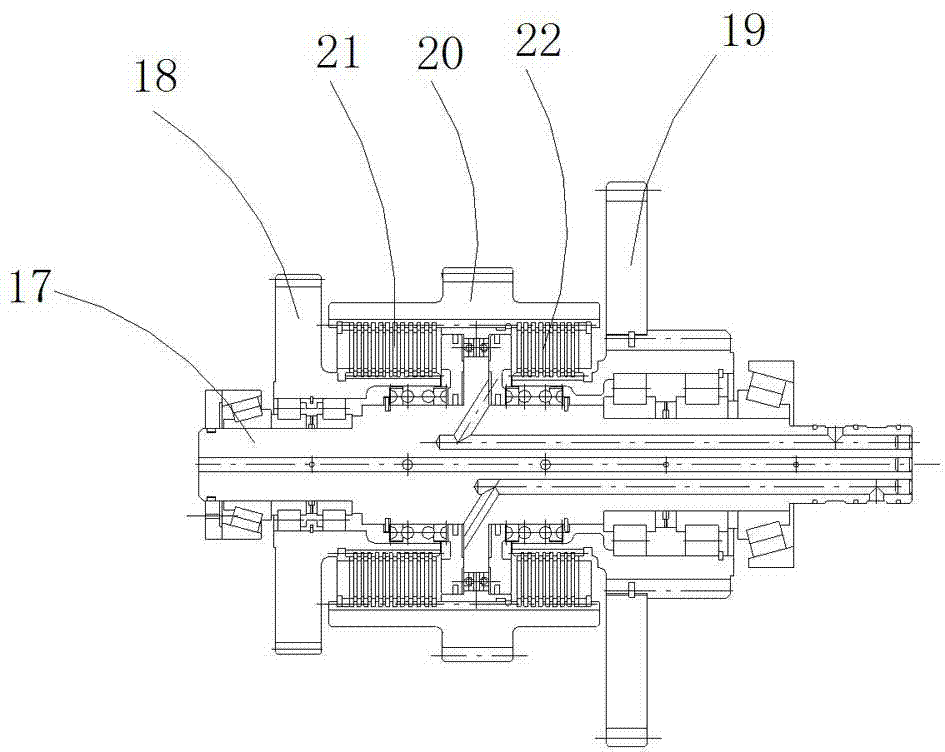

[0024] Example: such as figure 1 , figure 2 , image 3 and Figure 4As shown, a multi-gear and multi-degree-of-freedom moving shaft semi-automatic control gearbox includes a casing 1, and the casing is provided with a variable pump driving mechanism, a forward gear transmission mechanism, a reverse gear transmission mechanism, a fast gear The transmission mechanism and the output transmission mechanism, the variable pump drive mechanism is engaged with the forward gear transmission mechanism and the reverse gear transmission mechanism, and the forward gear transmission mechanism is meshed with the reverse gear transmission mechanism. The transmission mechanism is meshed with the fast gear transmission mechanism, and the fast gear transmission mechanism is meshed with the output transmission mechanism. The variable pump drive mechanism is located at the upper end of the box body 1. The forward gear transmission mechanism, reverse The gear transmission mechanism and the fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com