Biological microscope based hand-held type electro spark processing machine tool integrated with processing and measuring

A technology for processing measurement and processing machine tools, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of fixed NC resolution, inability to measure, and complex machine tool structure, etc., and achieve variable NC resolution , cost reduction, and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

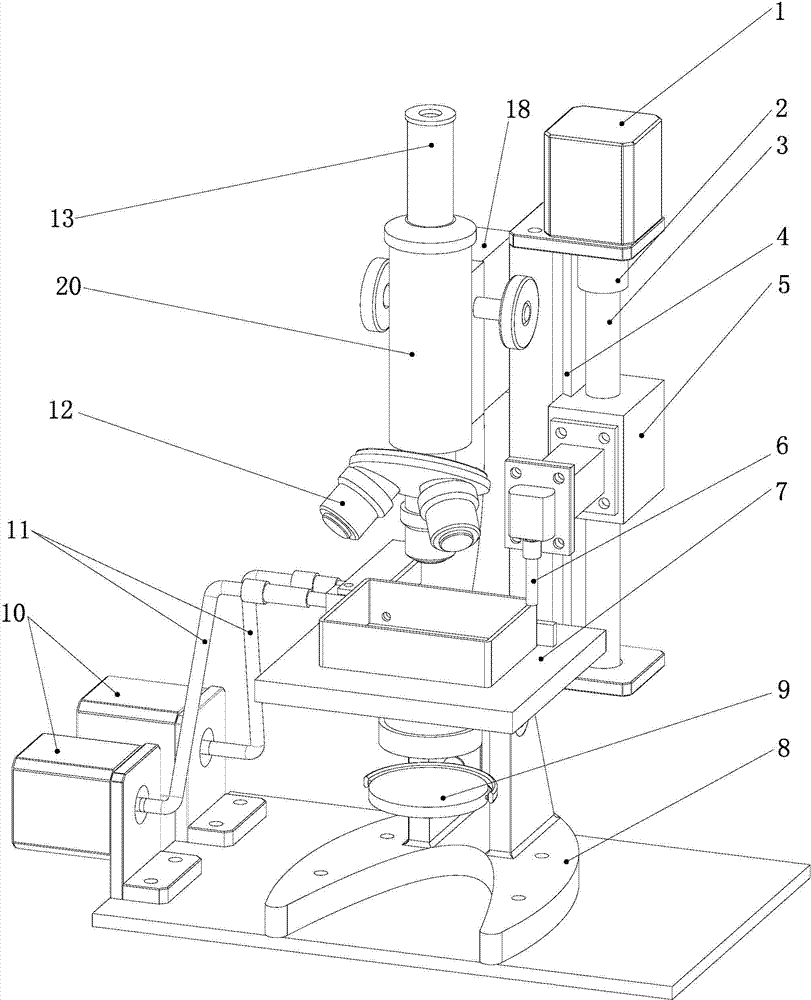

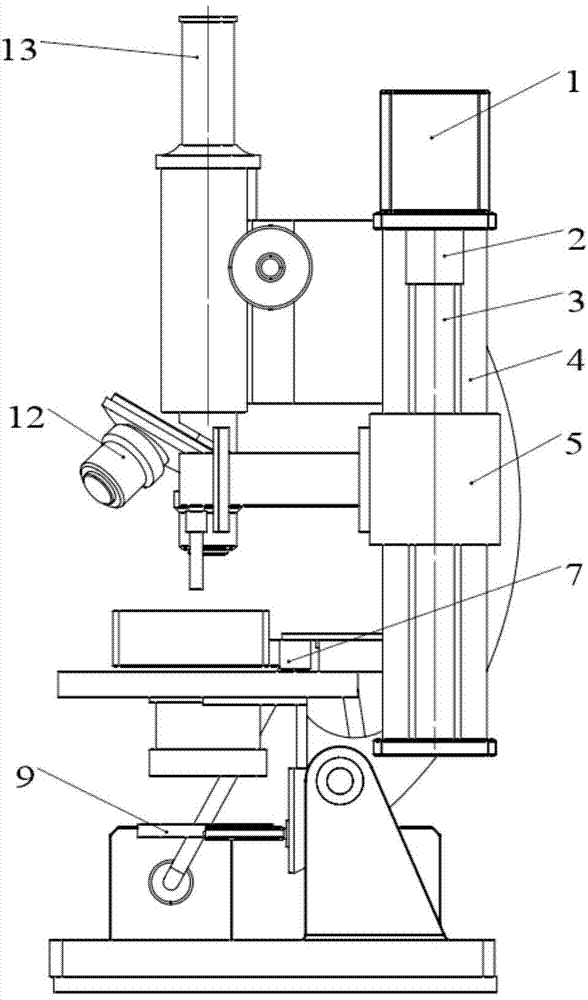

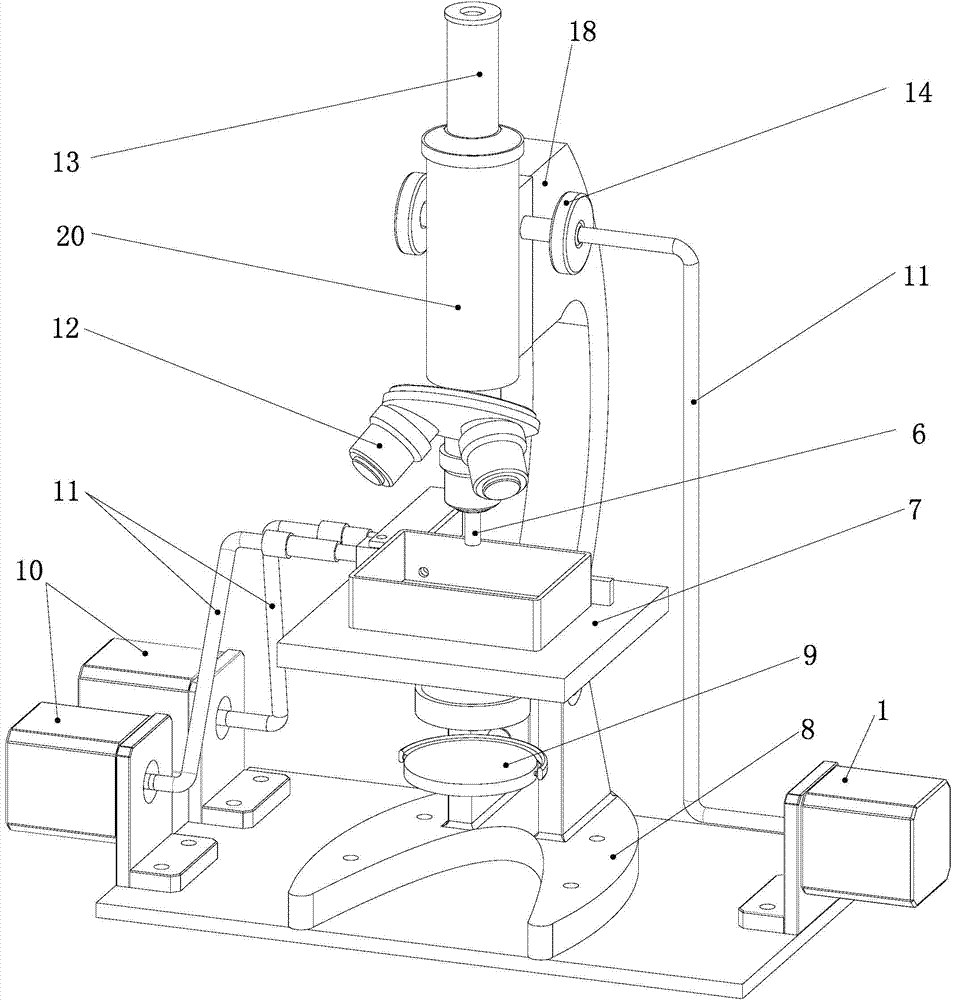

[0010] Specific implementation mode one: combine Figure 1-Figure 2 Illustrate that the integrated portable electric discharge machining machine tool based on the biological microscope of the present embodiment includes a biological microscope; the biological microscope includes a mechanical system and an optical system, and the optical system includes an objective lens 12, an eyepiece 13 and a condenser lens 9; the mechanical system includes a mirror arm 18. Lens barrel 20, base 8 and mobile workbench 7, the moveable workbench 7 and lens barrel 20 are all installed on the lens arm 18, and the lens barrel 20 is arranged with an adjustment handwheel 14 that can control the movement of the lens barrel 20 up and down; The workbench 7 is arranged with a horizontal adjustment handwheel capable of controlling the lateral movement of the mobile workbench 7 and a longitudinal adjustment handwheel for longitudinal movement; the eyepiece 13 is installed in the lens barrel 20, and an obje...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 To illustrate, the slider 5 of this embodiment is processed with a T-shaped groove, and the T-shaped groove is embedded in the guide rail 4 . With such setting, the slider connection is reliable and the movement is stable and continuous. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 and image 3 Note that the processing and measurement integrated portable electric discharge machining machine tool described in this embodiment also includes a coupling 2; the output shaft of the first stepping motor 1 is connected to one end of the vertically arranged ball screw 3 through the coupling 2 . With such arrangement, the connection between the first stepper motor 1 and the four-ball cylinder 3 is reliable and stable. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com