Multifunctional padding machine and padding method

A primer and multi-functional technology, applied in textiles and papermaking, removal of liquid/gas/steam, treatment of textile materials, etc., can solve the problems of single product variety and difficult standardization of product quality, and achieve advanced structure and high product quality Good, the process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

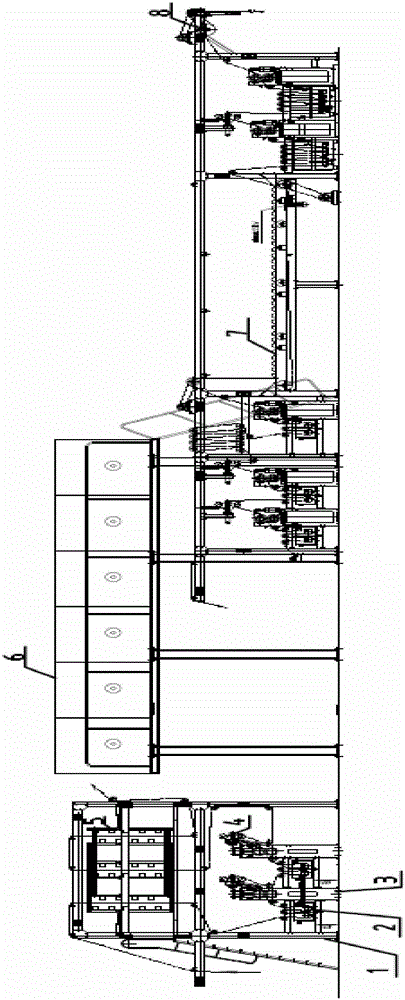

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] A multifunctional primer, comprising a support 1, an immersion tank 2, a rolling car 3, a tension frame 4, an infrared heating device 5, a drying chamber 6, a stacking mesh belt 7, and a cloth drop frame 8; The whole cloth feeding device is equipped with an infrared heating device behind the support, and the infrared heating device is used to pre-dry the fabric. After the infrared heating device, there is a immersion tank and a padding car. Tension frame with high fabric surface tension, behind the tension frame is a drying chamber, the inlet and outlet of the drying chamber are equipped with cooling rollers for cooling the cloth surface, behind the drying chamber is a stacking mesh belt for ventilating and oxidizing the fabric, After stacking the mesh belt, there is a cloth drop rack.

[0033] The primer machine also includes a PLC con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com