Bridge type transfer belt conveyor

A belt conveyor and bridge technology, which is applied in the fields of mining equipment and bridge transfer belt conveyors, achieves the effect of safe operation, high operation rate and small maintenance amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

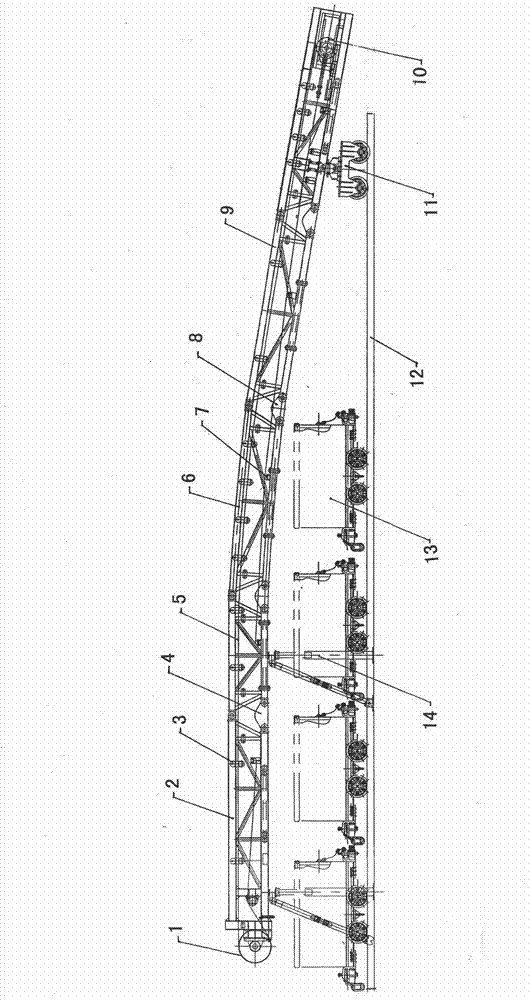

[0010] Such as figure 1 As shown, the described a kind of bridge transfer belt conveyor includes electric drum 1, head frame 2, upper idler roller 3, first connecting plate 4, adhesive tape 5, intermediate frame 6, lower idler roller 7, second Connecting plate 8, tail frame 9, tail wheel 10, tail frame running gear 11, track 12 and hydraulic prop 14, wherein said nose frame 2, intermediate frame 6 and tail frame 9 are made of metal profiles The frame body of the frame structure, the upper idler 3 and the lower idler 7 can use ZL02224286.4 "compact combined idler", ZL200420068798.5 "oilable idler" or ZL200520049715.2 "conveyor belt automatic deviation correction The idler (group) in ZL200520050521.4 "belt automatic deviation correction device" can also be designed according to the needs of the site. Its quantity greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com