Novel fabricated type steel structure stair cladding system

A prefabricated, steel structure technology, applied in the direction of stairs, stepped structures, building structures, etc., to achieve the effect of strong practicability, convenient operation and advanced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

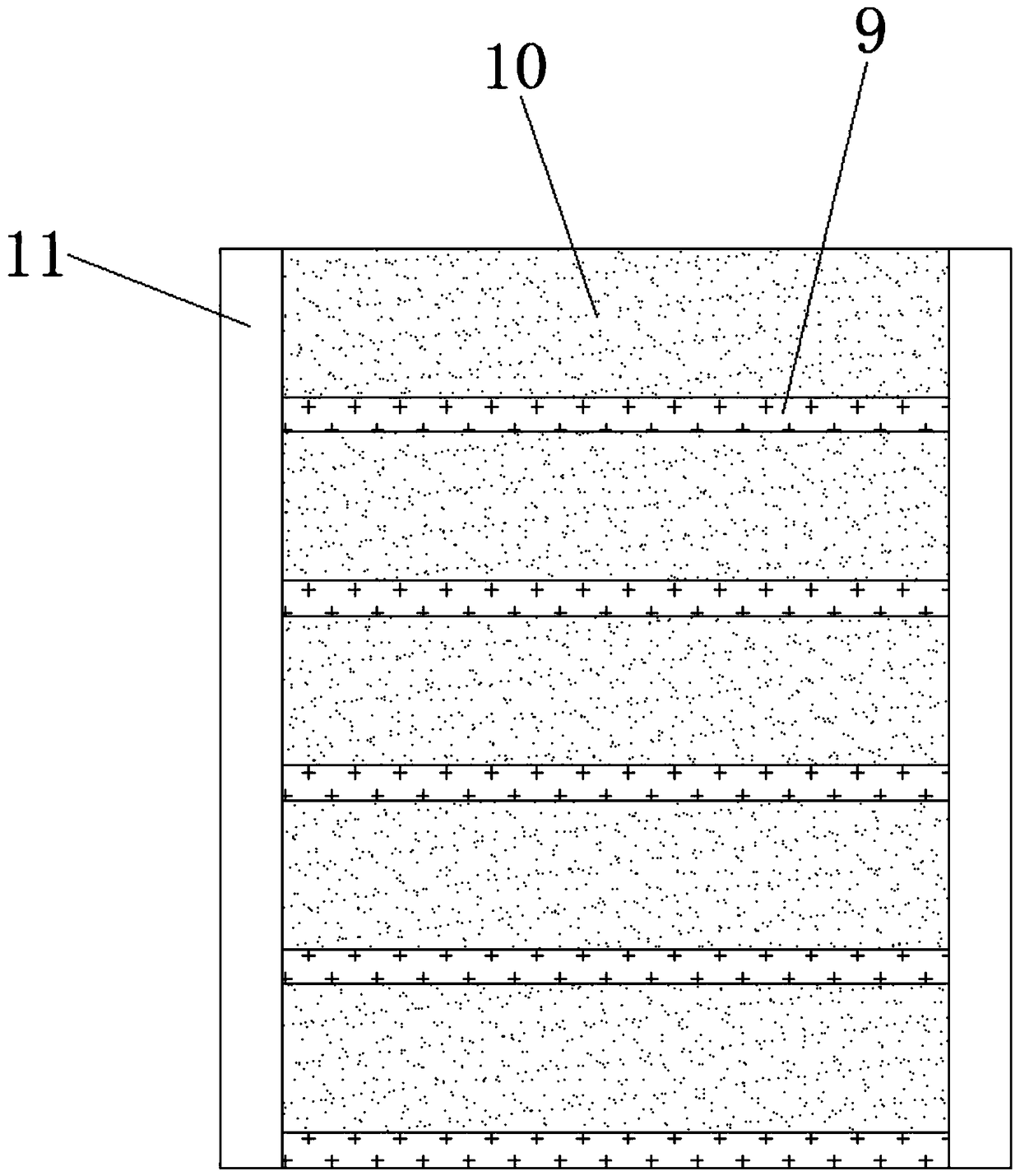

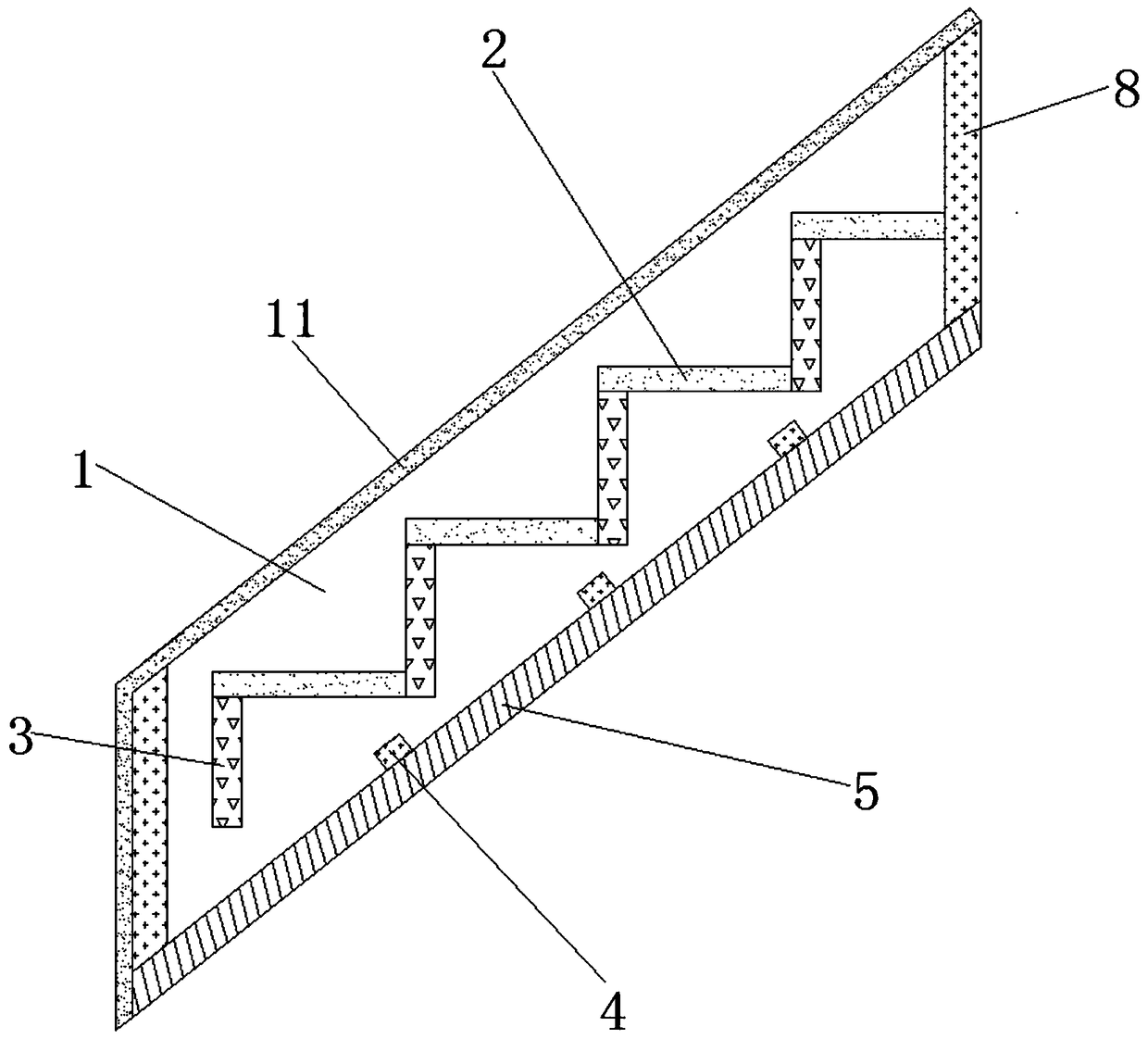

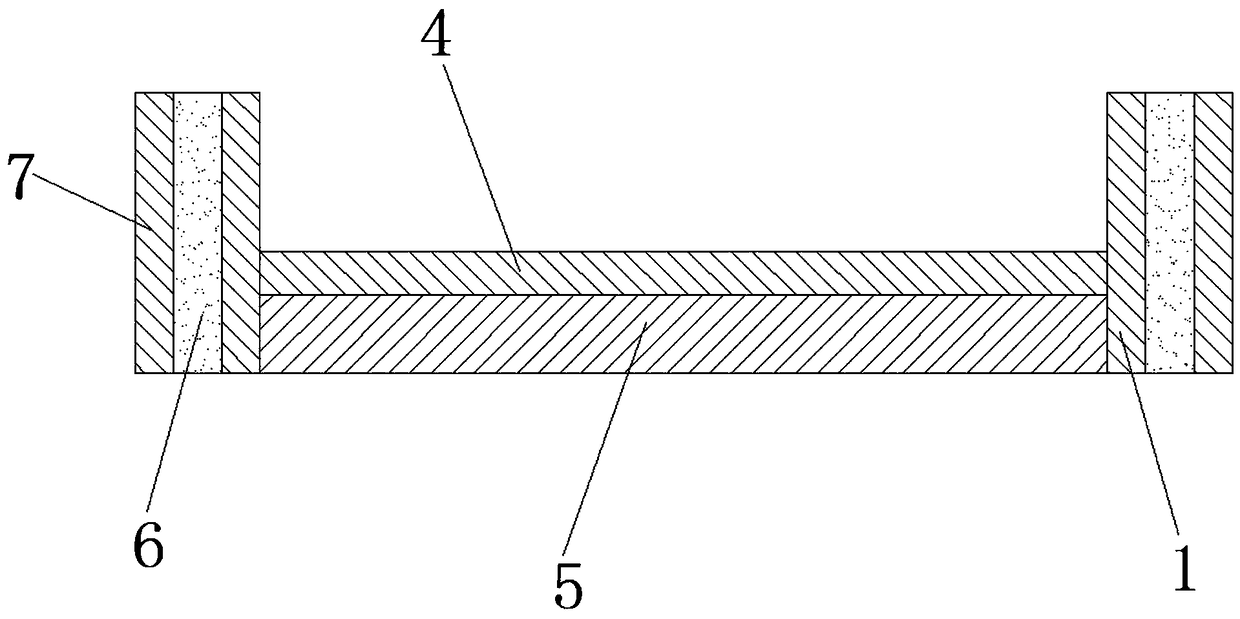

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the cladding system of the new fabricated steel structure stairs includes the side beam 1, the step 2, the kick surface 3, the square steel pipe 4, the bottom three-proof board 5, the first C-shaped keel 6, the side three-proof board 7, the third Two C-shaped keels 8, precast concrete step boards 9, precast concrete kick panels 10, and decorative stones 11, the number of the ladder side beams 1 is two, and the steps 2 and the kick surfaces 3 are located in pairs of the ladder side beams ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com