Patents

Literature

42results about How to "The process is simple and easy to operate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graphene oxide composite nano-filtration membrane

ActiveCN106823842AThe process is simple and easy to operateHigh water flux and separation performanceReverse osmosisGraphite oxideFiltration membrane

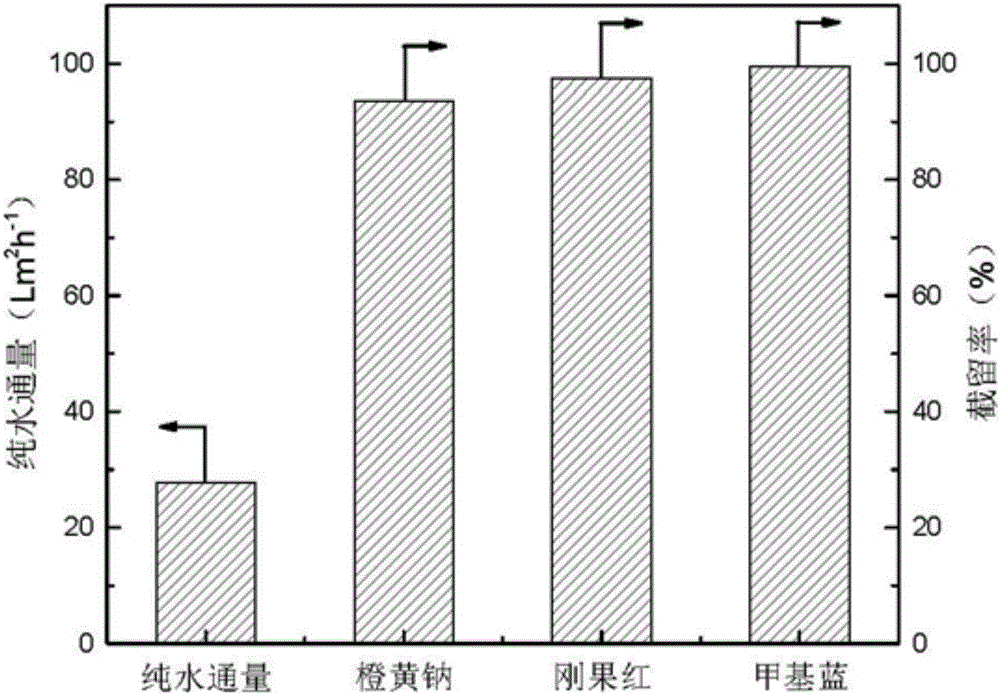

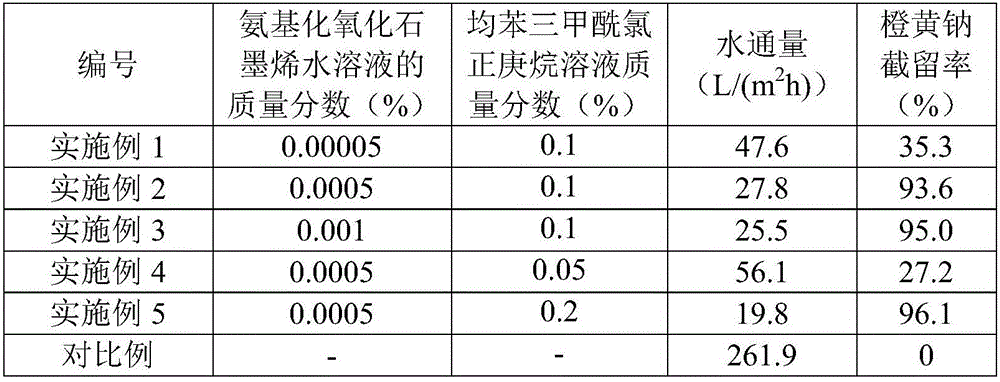

The invention discloses a preparation method of a graphene oxide composite nano-filtration membrane. The method mainly comprises the following steps: preparing a polyethersulfone ultra-filtration base membrane by adopting a phase inversion method; carrying out surface grafting to prepare aminated graphene oxide; sequentially immersing the polyethersulfone ultra-filtration base membrane into a low-concentration water-phase monomer aminated graphene oxide and organic monomer trimesoyl chloride solution; carrying out interface polymerization to prepare the graphene oxide composite membrane. The preparation method disclosed by the invention has the advantages that the aminated graphene oxide is used for carrying out the interface polymerization of a water-phase monomer and a process is simple and easy to operate; compared with a polyamide separation membrane prepared by a traditional interface polymerization method, a separation layer of the prepared graphene oxide composite membrane is very thin and the graphene oxide composite membrane has relatively high water flux and separation performance under relatively low operation pressure (0.2MPa).

Owner:TIANJIN UNIV

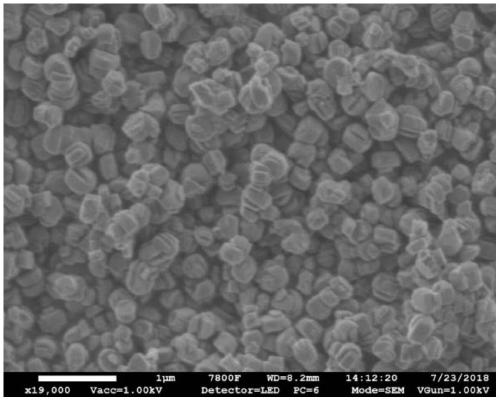

Preparation method of WCu composite powder with tungsten coating copper

InactiveCN103537686AThe process is simple and easy to operateReduced calcination processCoatingsIonSal ammoniac

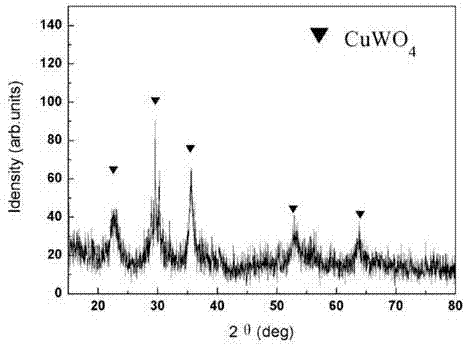

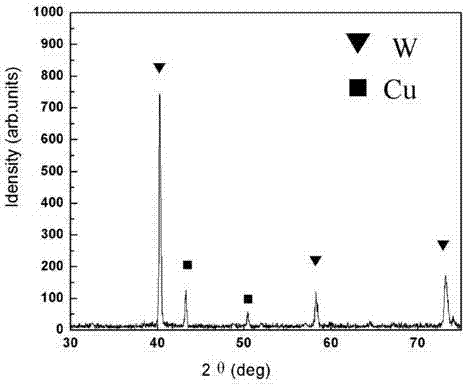

The invention relates to the filed of WCu composite powder preparation, in particular to a preparation method of WCu composite powder with tungsten coating copper. The preparation method includes: selecting sodium tungstate dihydrate and copper nitrate trihydrate according to the atomic concentration of 1:1 as raw materials to prepare corresponding solution, adding ammonia water to the obtained copper nitrate trihydrate solution to allow sufficient copper complex ions to be generated in the solution, adjusting pH of the solution and filling the solution to a stainless steel reaction kettle to prepare CuWO4 nano particles, and performing staged reduction to obtain the WCu composite powder. Compared with the traditional preparation methods of tungsten copper oxide, the preparation method has the advantages that sufficient copper complex ions are generated in the solution by adding ammonia water to the copper nitrate solution, and accordingly recycling rate of Cu is increased, the WCu composite power with tungsten coating copper and good interface combination is generated in subsequent hydrogen reduction of the obtained CuWO4, and the prepared WCu composite powder is well mixed, fine in particle and high in purity.

Owner:HENAN UNIV OF SCI & TECH

Treatment technique suitable for high salt and high concentrated organic wastewater

InactiveCN101381190AEfficient processThe process is simple and easy to operateFatty/oily/floating substances removal devicesMultistage water/sewage treatmentChemistryPetroleum

The invention provides a treatment process applicable to high-salinity high-concentration organic wastewater. Aiming at three types of high-salinity high-concentration organic wastewater (wherein contained salts are NH4Cl, MgCl2 and MgSO4), the invention adopts physical adsorption, oil-phase and aqueous-phase separation, coagulation and air-flotation, oxidation, concentration and crystallization, oxidation, biological treatment and a series of processes for treatment. The treatment process removes COD and NH3-N in the wastewater, ensures that the pH value of the wastewater can meet the secondary discharge standard of the petrochemical industry class in Integrated Wastewater Discharge Standard (GB8978-1996), and can recover useful salt materials, namely NH4Cl, MgCl2.6H2O and MgSO4.7H2O (content accounts for 10 to 20 percent of raw water) from the three types of wastewater. The treatment process obtains remarkable economic benefit at the same time of treating sewage, and can also be used for reducing the cost for sewage treatment. The treatment process has the advantages of low cost, high efficiency, easy operation and no secondary pollution, and is applicable to the treatment of the high-salinity high-concentration organic wastewater.

Owner:YUNNAN UNIV

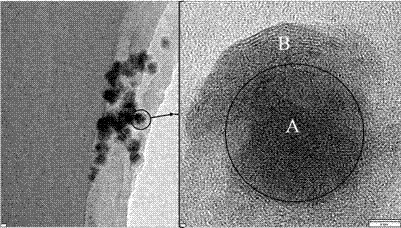

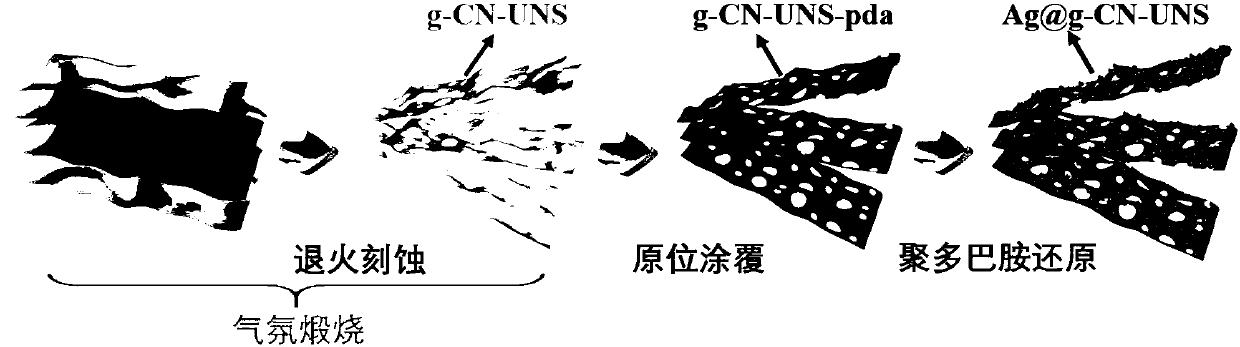

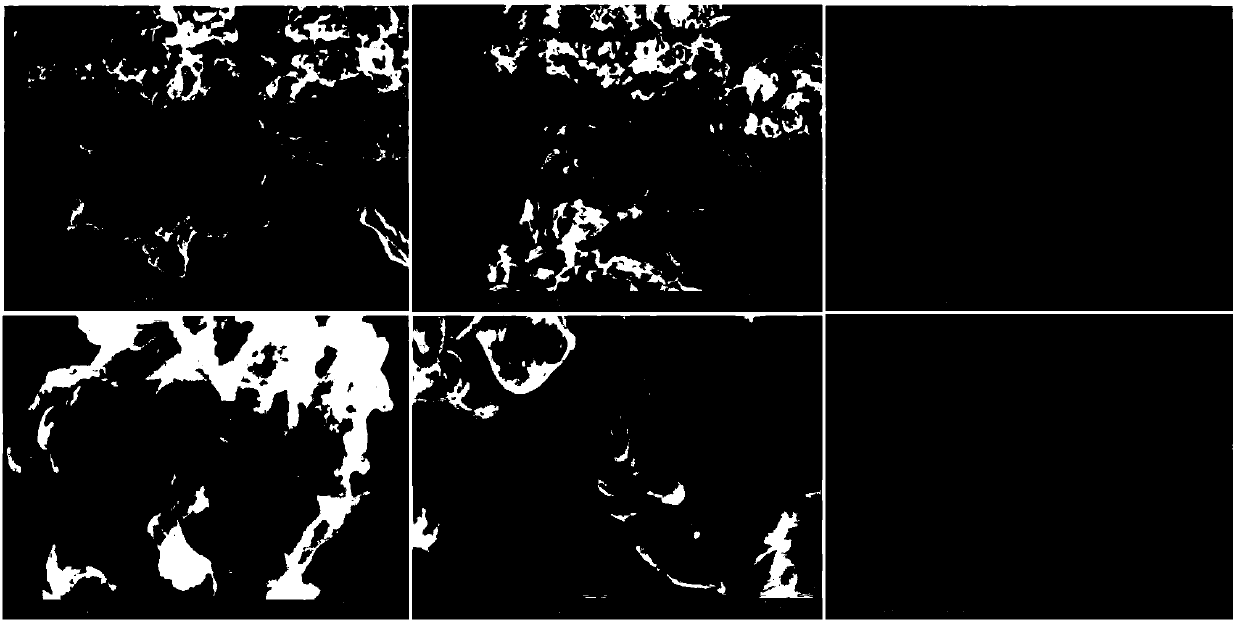

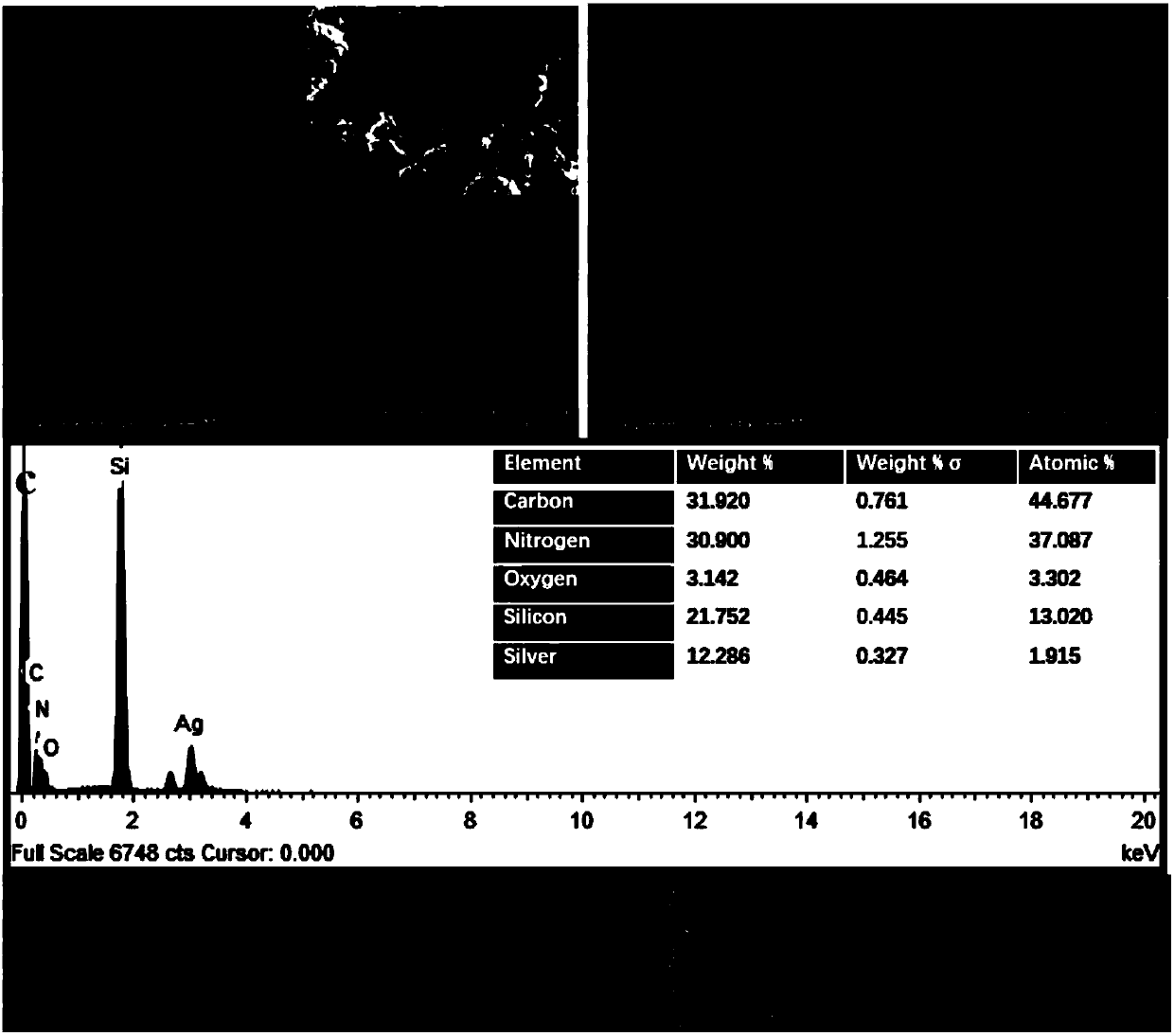

Preparation method and application of novel silver-nanoparticle modified ultrathin graphite phase carbon nitride catalyst

InactiveCN107684924AThe process is simple and easy to operateControllable sizePhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationUrea

The invention discloses a preparation method and application of a novel silver-nanoparticle modified ultrathin graphite phase carbon nitride catalyst. The method includes: subjecting urea to heat treatment to obtain lump graphite phase carbon nitride; subjecting the lump graphite phase carbon nitride to secondary heat treatment to obtain an annealing etched ultrathin graphite phase carbon nitridelayer; structuring a bionic mussel polydopamine biocoating on ultrathin graphite phase carbon nitride by adopting an impregnation method; based on polydopamine modification and by the aid of reducibility of silver nanoparticles, loading the silver nanoparticles on the surface of the ultrathin graphite phase carbon nitride. The two-dimensional ultrathin graphite phase carbon nitride layer is prepared by adopting the high-temperature annealing method, the silver nanoparticles are prepared by adopting the green bionic method of self-polymerization polydopamine, and good prospects of the novel composite high-activity photocatalyst are displayed in the field of organic pollutants like photocatalytic degradation of methylene blue and phenol.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

Carbon fiber composite material reinforcing process

InactiveCN102409867AThe process is simple and easy to operateQuality assuranceBuilding repairsCarbon fiber compositeHardness

The invention discloses a carbon fiber composite material reinforcing process which comprises the following steps of: scribing on a concrete surface to determine the position for sticking carbon fiber cloth; polishing to flatten the concrete surface where the carbon fiber cloth is located, cleaning the polished concrete surface, and keeping the concrete surface dry and clean; uniformly sticking primer on the concrete surface, and soaking in concrete; after the primer is dried, repairing and filling up the sunk part of the concrete surface; cutting the carbon fiber cloth and storing while avoiding dust and sundries on the surface of the carbon fiber cloth; preparing impregnation glue; smearing bottom impregnation glue; sticking the carbon fiber cloth; smearing upper impregnation glue; maintaining the carbon fiber cloth to achieve the required hardness; and protecting the last layer of the surface of the carbon fiber cloth. The process disclosed by the invention is simple and easy to operate, ensures quality and is safe and environment-friendly.

Owner:BORUISI TECH DALIAN

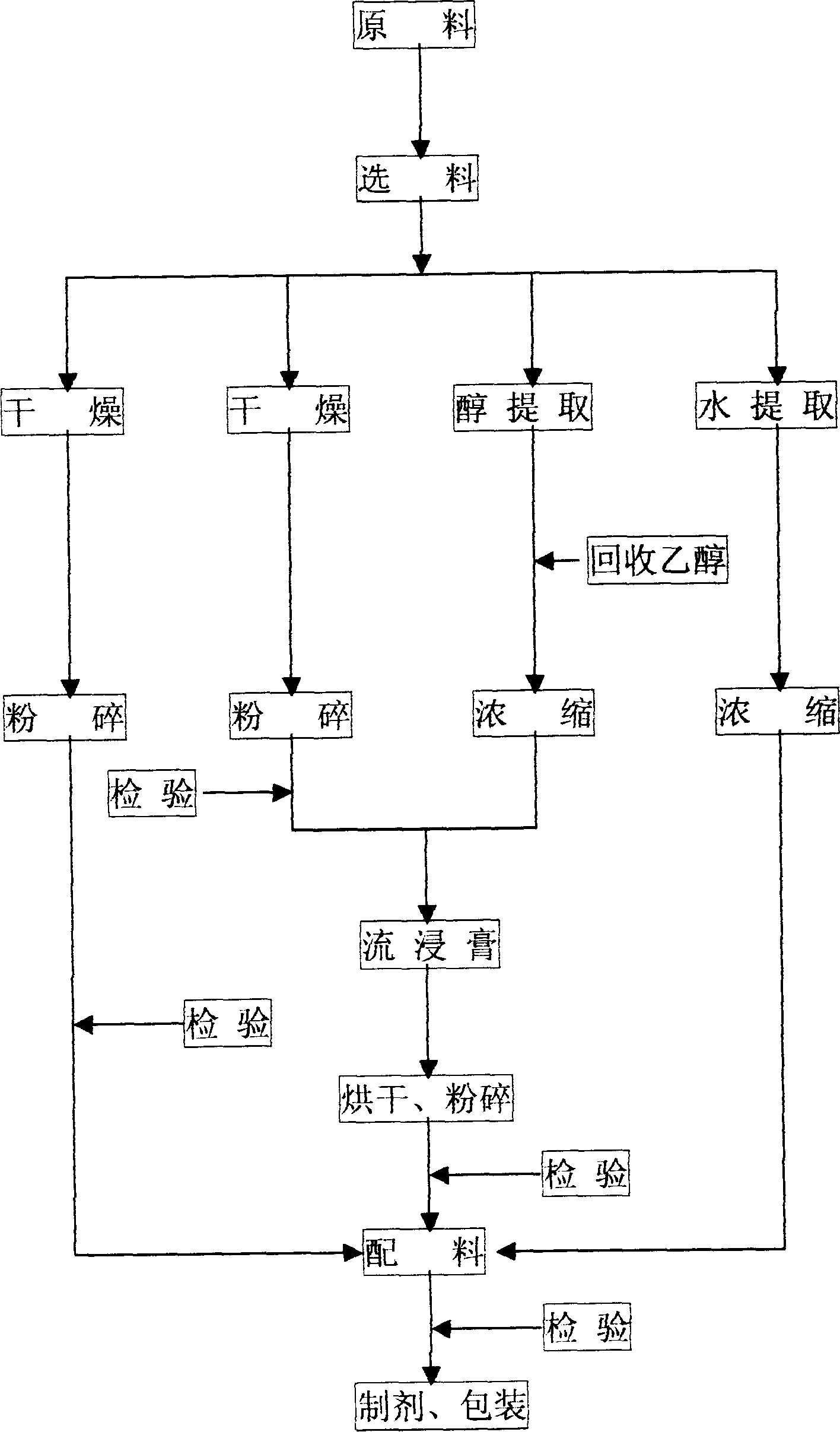

Nutritious health care food and preparation prlcess thereof

InactiveCN1483450ASimple processThe process is simple and easy to operateDigestive systemUnknown materialsNutrientPhysiological function

The present invention relates to a nutrient health-care food with the functions of regulating physiological function of human body, raising immunity of human body, nourishing yin and strengthening yang and quickly raising sexual function. Said nutrient health-care food is made up by using velvet deerhorn, ginseng, epimedium, dioscorea root, lycium berry, flowery knotweed, morinda root and Chinese leak seed.

Owner:鲁骏

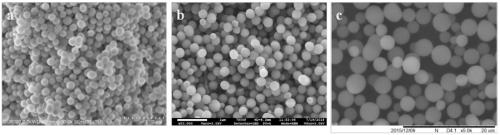

Preparation method of particle diameter controllable monodisperse polystyrene microspheres

InactiveCN102649826AThe process is simple and easy to operateSimple processBatch productionPolystyrene microsphere

The invention relates to a preparation method of particle diameter controllable monodisperse polystyrene microspheres. The particle diameter controllable monodisperse polystyrene microspheres are prepared from the following raw materials in percentage by mass: 5.0-40.0 percent of styrene monomer, 0.025-0.125 percent of initiator, 0.1-2.0 percent of dispersant and the balance of reaction medium. Through excellent formula proportion design, the contents of the monomer and the dispersant are changed to achieve the effect of controlling the preparation of the monodisperse polystyrene microspheres of different particle diameters; the process is simple and easy to operate; batch production scale can be achieved; and industrialization can be easily realized.

Owner:UNISIZE TECH CHANGZHOU

Method for treatment of high-salinity and high-concentration organic wastewater through process of high-efficiency photocatalytic vacuum separation of gas phase, liquid phase and solid phase

ActiveCN101767913AEfficient processThe process is simple and easy to operateWater/sewage treatment by irradiationDispersed particle separationSolid phasesChemistry

The invention relates to a method for treatment of high-salinity and high-concentration organic wastewater (wherein salts can be NH4Cl, MgCl2, MgSO4, NaCl, Na2SO4, Na2HPO4 and the like) through a series of processes comprising pretreatment, pH adjustment, high-efficiency photocatalytic separation of gas phase, liquid phase and solid phase and advanced treatment. When the invention is used, the effluent quality can meet the requirements of secondary discharge standards of the category of petroleum and chemical in the Integrated Wastewater Discharge Standard (GB8978-1996), and salt can be recycled from wastewater. In addition, in order to avoid secondary pollution, the invention realizes the photocatalytic treatment of exhaust generated by the high-efficiency photocatalytic separation of the gas phase, the liquid phase and the solid phase, and most of the organic substances in the exhaust can be degraded to remove odor. Moreover, the invention proposes the view of treating waste with waste, namely, feeding the exhaust generated by wastewater into raw wastewater or other kinds of raw wastewater, thereby reducing the exhaust emission and further lowering the difficulty in photocatalytic treatment of the exhaust. The invention has the advantages of low cost, high efficiency, easy operation and no secondary pollution, and is applicable to the treatment of high-salinity and high-concentration organic wastewater.

Owner:YUNNAN UNIV

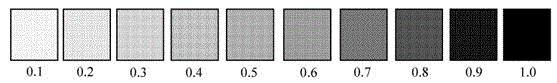

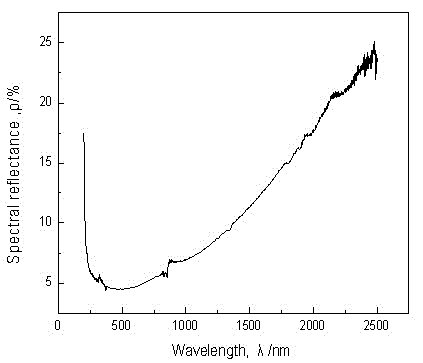

Process for preparing high-light-absorption-rate black ceramic film layer through micro-arc oxidation of surface of magnesium alloy

InactiveCN104694993AThe process is simple and easy to operateReduce environmental pollutionAnodisationMicro arc oxidationAbsorption rate

The invention discloses a process for preparing a high-light-absorption-rate black ceramic film layer through micro-arc oxidation of the surface of a magnesium alloy. In an electrolyte solution with silicate or phosphate as a main salt, the magnesium alloy is subjected to micro-arc oxidation treatment by an alternating-current bipolar pulse power source. The electrolyte solution for preparing the high-light-absorption-rate black ceramic film layer through micro-arc oxidation of the surface of the magnesium alloy is simple in composition and easy to operate, and has less pollution to the environment; the prepared black ceramic film layer not only has the performance of good corrosion resistance and high light absorption rate, but also has good apparent decoration, and can satisfy practical application requirements.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-heat-conducting carbon/carbon composite material and preparation method thereof

The invention relates to a high-heat-conducting carbon / carbon composite material and a preparation method thereof, and belongs to the technical field of carbon material manufacturing. The preparationmethod comprises the following steps: alternately laying a carbon fiber cloth and intermediate phase asphalt felt to obtain a laminated structure, wherein the thermal conductivity of the carbon fibercloth is greater than 500W / mK at room temperature; carrying out hot-pressing forming on the laminated structure, and carrying out high-temperature treatment and high-pressure graphitizing treatment toobtain the high-heat-conducting carbon / carbon composite material. The method has the advantages of simple process, little time consumption, low energy consumption and the like, and the preparation rate and efficiency of the high-heat-conducting carbon / carbon composite material can be greatly improved. The prepared high-heat-conducting carbon / carbon composite material has a uniform internal structure and excellent heat conduction and mechanical properties, and has wide application prospects in the aspects of heat control and heat management in the fields of aerospace, nuclear reactor, electronic industry and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

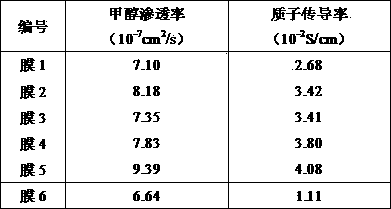

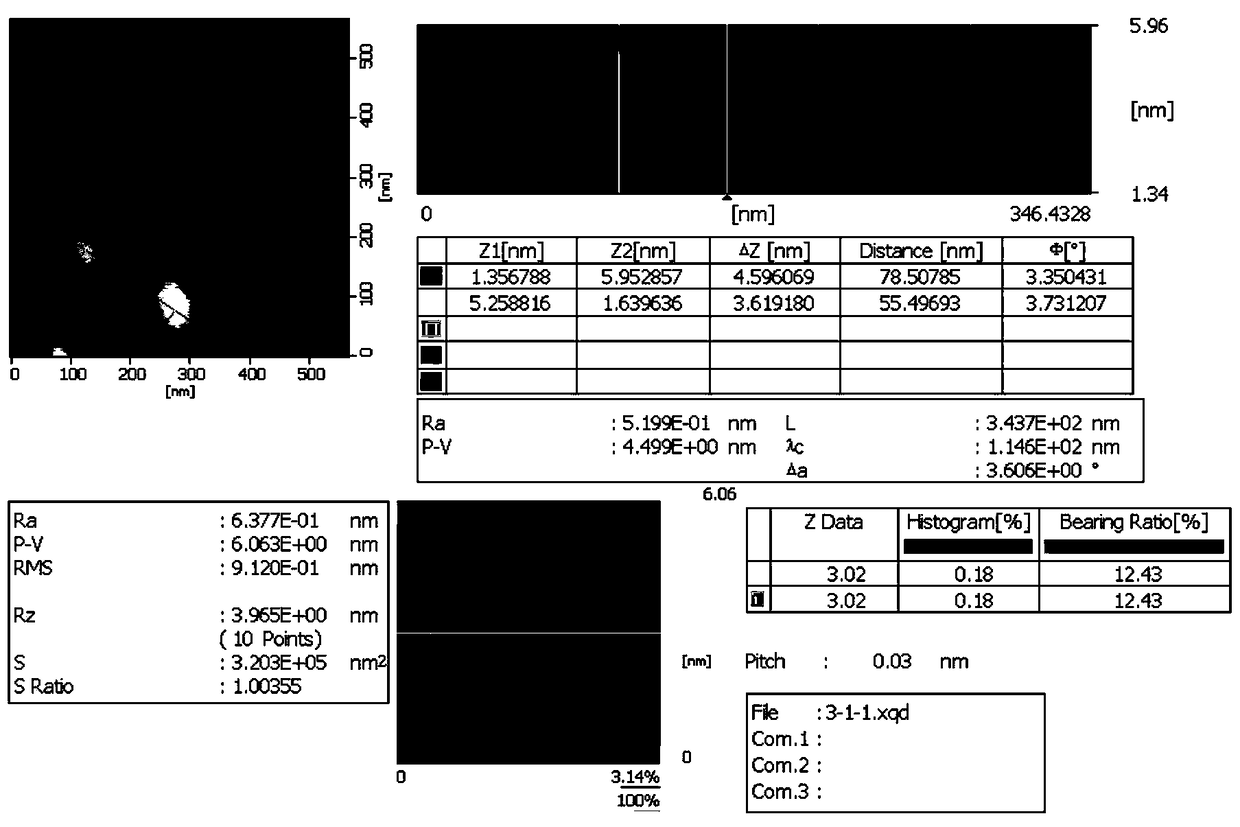

Chitosan/in-situ amphoteric silicon-titanium hybrid film as well as preparation method and application thereof

InactiveCN103849011AThe process is simple and easy to operateAvoid reunionFinal product manufactureCell component detailsChemistrySol-gel

The invention discloses a chitosan / in-situ amphoteric silicon-titanium hybrid film as well as a preparation method and an application thereof. The thickness of the hybrid film is 80-120 microns, the hybrid membrane is composed of chitosan, silicon dioxide and titanium dioxide. The preparation process comprises the following steps: preparing a chitosan solution, mixing amphoteric inorganic silicon-titanium sol and the chitosan solution to perform condensation polymerization to obtain a casting film solution, performing casting film process on the casting film solution to obtain the chitosan / in-situ amphoteric silicon-titanium hybrid film. The hybrid film is used as a direct-methanol fuel cell proton exchange membrane. The preparation method is simple and easy to operate, acid-stage group and basic group co-exist in inorganic particles in the film, the in-situ sol-gel method enables the nano-level silicon-titanium particles to be uniformly distributed in the hybrid film, the performance of the film is effectively improved, and the hybrid film has low methanol permeability and high proton conduction.

Owner:TIANJIN UNIV

Bismuth quantum dot and preparation method thereof

ActiveCN108247069ASimple processThe process is simple and easy to operateMaterial nanotechnologyTransportation and packagingBismuthQuantum dot

The invention provides a preparation method of a bismuth quantum dot. The preparation method comprises the steps that firstly, bismuth powder is scattered in an organic solvent, and dispersion liquidis obtained; secondly, primary water bath ultrasonic treatment is firstly carried out on the dispersion liquid, probe type ultrasonic treatment is carried out, first ultrasonic liquid is obtained, secondary water bath ultrasonic treatment is carried out on the first ultrasonic liquid, and secondary ultrasonic liquid is obtained; and thirdly, low-speed centrifugation is carried out on the secondaryultrasonic liquid at the speed of 2000 rpm-7000 rpm, first liquid supernatant is collected, high-speed centrifugation is carried out on the first liquid supernatant at the speed of 9000 rpm-12000 rpm, secondary liquid supernatant is collected, and the bismuth quantum dot is obtained. According to the method, the process is simple, operation is easy, reproducibility is good, and the size controllable bismuth quantum dot with good monodispersity is easily prepared. The invention further provides the prepared bismuth quantum dot.

Owner:SHENZHEN UNIV

Efficient flame retardant two-component polyurethane adhesive

InactiveCN106244080ASimple processThe process is simple and easy to operateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveCohesive strength

The invention discloses an efficient flame retardant two-component polyurethane adhesive comprising the following components and the weight parts of the corresponding components: 40 parts by weight of polyester polyol; 28 parts by weight of calcium carbonate; 20 parts by weight of a flame retardant; and 2 parts by weight of molecular sieve. Even if the flame retardant is added in the two-component polyurethane adhesive, no obvious influence on the properties of an original two-component polyurethane adhesive exists, and the original cohesive strength, bonding strength, color appearance, viscosity, application time, foaming rate and main solid ratio can be substantially kept.

Owner:SHANGHAI HAOYU CHEM CO LTD

Production technology of high viscosity sodium carboxymethyl cellulose

InactiveCN106699901AReduce manufacturing costThe process is simple and easy to operateSide productSodium carboxymethylcellulose

The invention relates to a production technology of high viscosity sodium carboxymethyl cellulose. The production technology comprises the steps of washing raw materials; smashing; conducting an alkalization reaction, wherein smashed cotton clothes and cotton fabric are put into an alkalization kneading machine, air in the alkalization kneading machine is pumped out and inert gas is pumped into the alkalization kneading machine, the step is repeated for multiple times until vacuum degree in the alkalization kneading machine reaches 0.005 Mpa, and the alkalization reaction is conducted under the protection of the inert gas; conducting an etherification reaction, wherein the alkalized product is put into an etherification kneading machine to be subjected to the etherification reaction; washing; neutralization; centrifugation; drying; obtaining the product after smashing. According to the production technology of the high viscosity sodium carboxymethyl cellulos, discarded cotton clothes and cotton fabric are adopted as raw materials, waste is turned into wealth, the production cost is drastically reduced, the technology is easy to operate, the side product is less, the quality index of the obtained product reaches viscosity 1% B type (Brookfield Viscosity)>7000 mpa.s, the substituted ratio is bigger than 0.95, and the purity is bigger than 99.5%.

Owner:TIANJIN RUNSHENG CELLULOSE TECH

Method for extracting and purifying oleanolic acid and Ligustrum lucidum Ait

InactiveCN101817864ASimple processThe process is simple and easy to operateSugar derivativesSteroidsChemistryLigustrum lucidum

The invention relates to a method for separating and purifying oleanolic acid and Ligustrum lucidum Ait, which easily realizes industrialization. The method comprises the following process steps: ethanol extraction, separation of the oleanolic acid and the Ligustrum lucidum Ait in low alcohol, alkali alcohol treatment, ethanol dissolution, crystallization and purification of the oleanolic acid, macroporous resin chromatography and extraction, crystallization and purification of Ligustrum lucidum Ait. The method for producing the oleanolic acid and the Ligustrum lucidum Ait has the advantages of simple process, high utilization rate of raw materials and low cost.

Owner:苏州宝泽堂医药科技有限公司

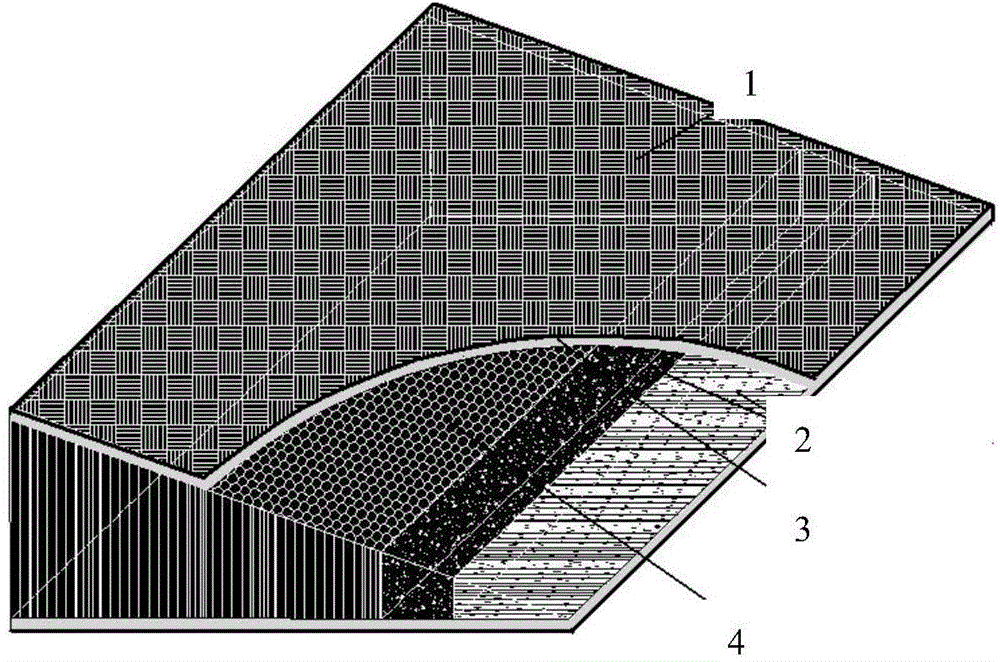

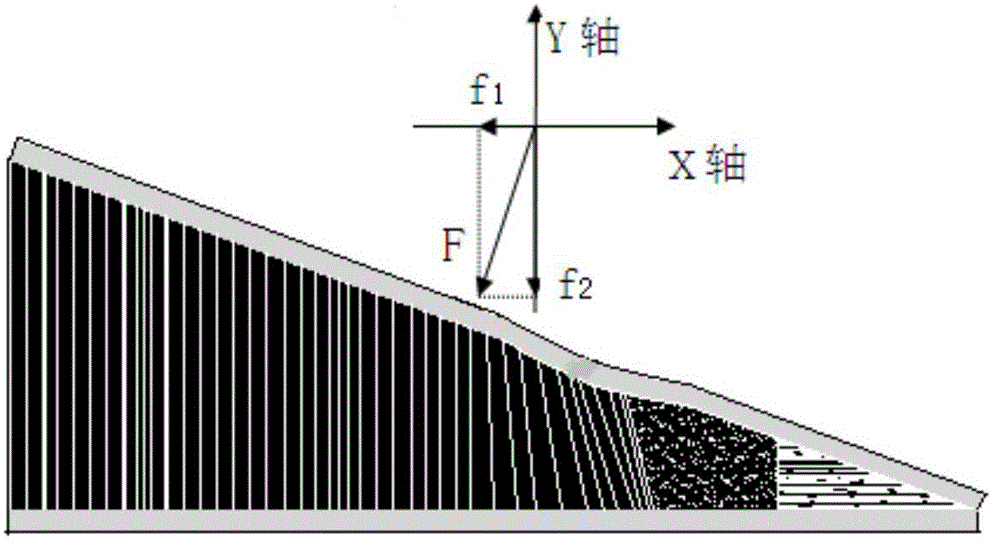

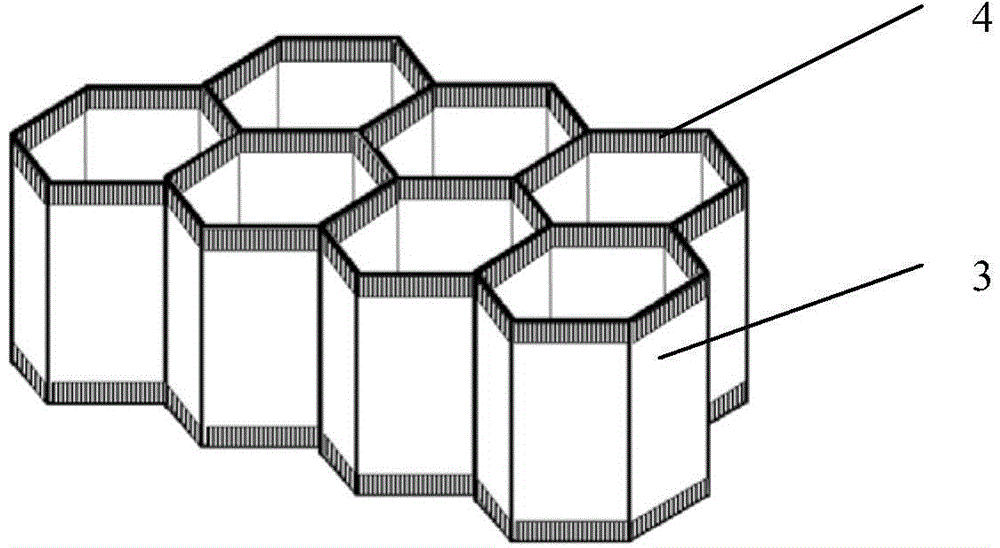

Method for reinforcing surface stability of core of honeycomb-like porous structure by hot film blowing and breaking method

ActiveCN104553238ALess weight gainThe process is simple and easy to operateLamination ancillary operationsLaminationHoneycombAerospace

The invention belongs to the technical field of composite materials, and relates to a technological method for reinforcing the surface stability of a core of a honeycomb-like porous structure in the manufacturing process of a honeycomb core sandwich structure in an aerospace craft, and particularly relates to a method for reinforcing the surface stability of the core of a honeycomb-like porous structure by a hot film blowing and breaking method. The method comprises the following steps: before manufacturing the sandwich structure, firstly, sticking an adhesive film on the surface of the honeycomb-like porous structure, breaking pores of the adhesive film by a hot film blowing and breaking method and sticking on the side wall of a honeycomb core hole cell, and then carrying out heating and curing treatment so that the adhesive film forms an adhesive stream and shaped on the wall of the core of the honeycomb-like porous structure. An organic integer is formed on the surface of the honeycomb core by the method, and the intensity and rigidity of the surface of the honeycomb core are reinforced. When the structure is pressed, the pressure can be transferred and dispersed timely, so that the possibility of buckling failure of a partial weak region is reduced, the surface stability of the structure is reinforced effectively, and the integral pressure resistant capability is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

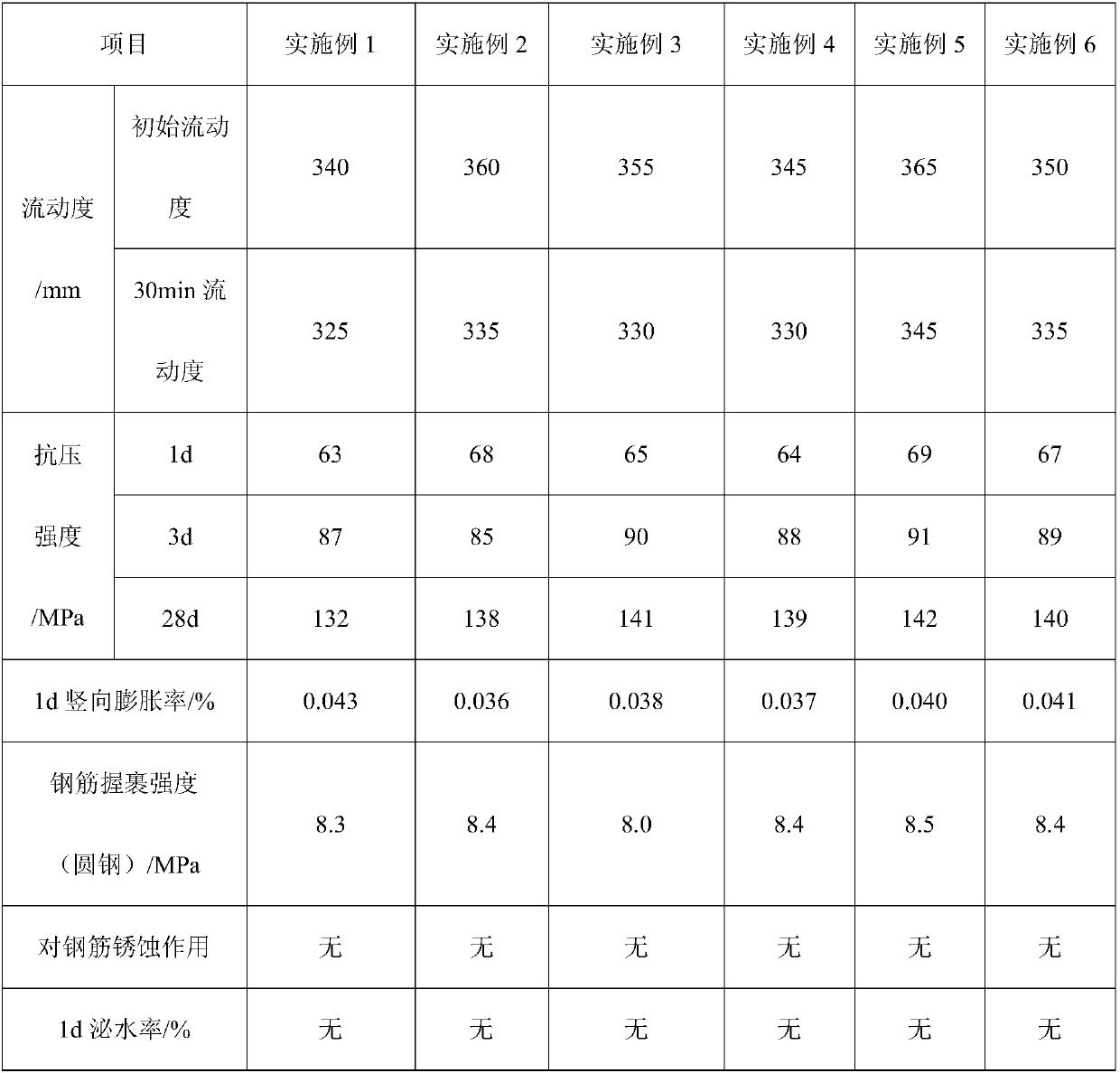

High-strength shrinkage-free cement-based grouting material and preparation method and application thereof

The invention provides a high-strength shrinkage-free cement-based grouting material and a preparation method and application thereof. The high-strength shrinkage-free cement-based grouting material is prepared from, by weight, 400-500 parts of cement, 480-550 parts of sand, 0-15 parts of silica sand powder, 10-15 parts of expanding agent, 15-50 parts of silica fume, 2.5-4 parts of water reducingagent, 0.3-0.4 part of plastic expanding agent and 0-0.1 part of defoaming agent. When the grouting material is applied, the grouting material is in a self-flowing state only by adding water and stirring, no bleeding is produced, initial fluidity is greater than or equal to 340 mm, the fluidity is greater than or equal to 325 mm after 30 minutes, a grouting hole is directly filled with the grouting material, and all voids can be filled without vibration. The high-strength shrinkage-free cement-based grouting material has super-good early strength performance, the compressive strength of 1 dayis greater than or equal to 60 MPa, the strength of 3 days is greater than or equal to 85 MPa, the strength of 28 days is greater than or equal to 132 MPa, and normal operation can be achieved in 1 day after construction. The grouting material has a micro-expansion effect, and direct and tight contact between devices and a foundation is ensured. In addition, the grouting material does not corrodesteel bars, is resistant to oil contaminations, can be used for anchorage of foundation bolts, secondary grouting of the devices and the foundation, building reinforcement and repair, prefabricated concrete member sleeve connection and other projects.

Owner:河南力行科创矿山技术开发有限公司

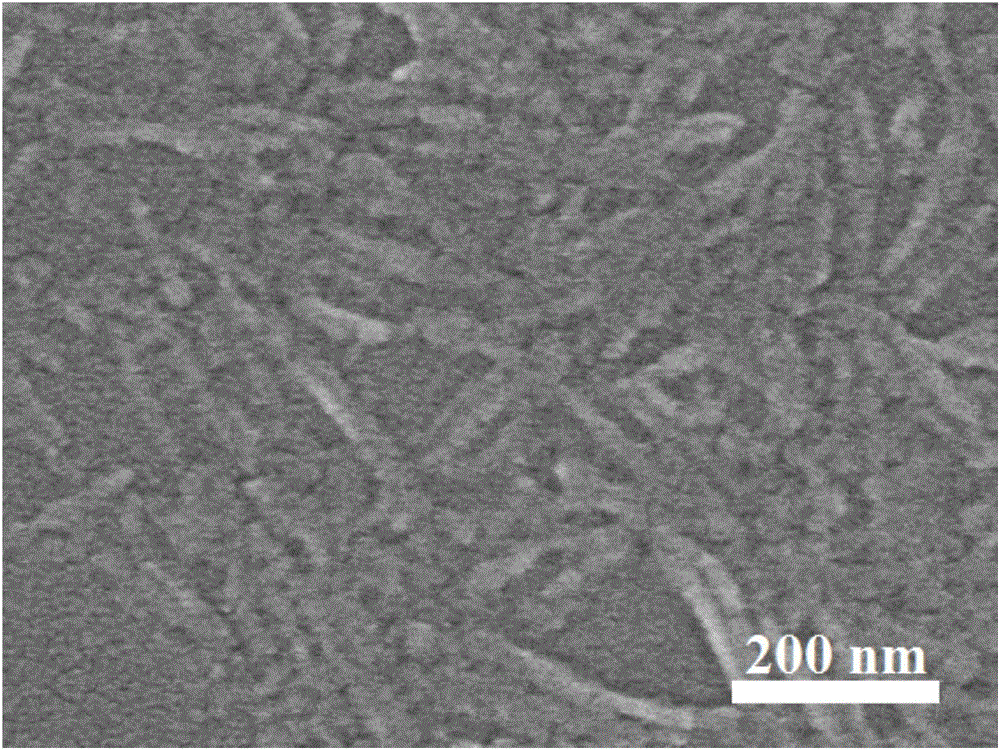

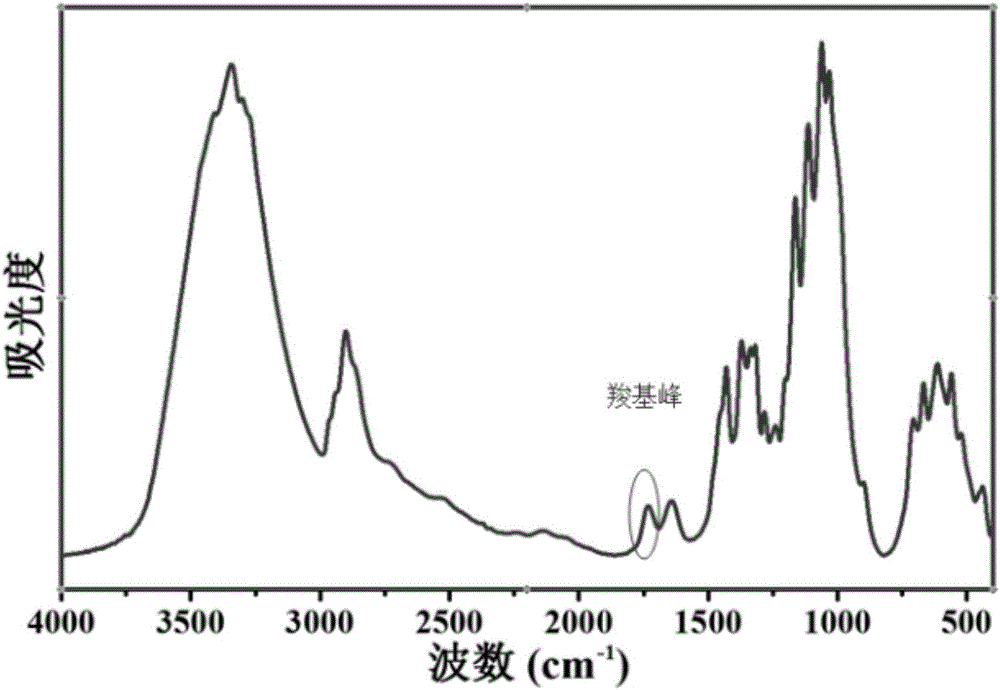

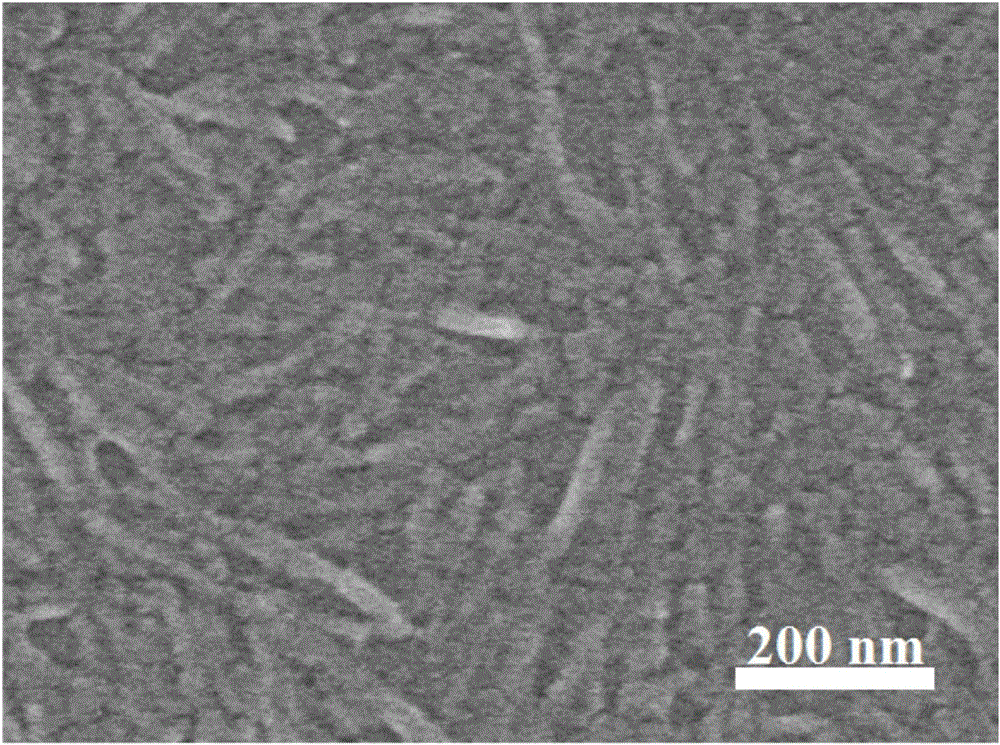

Preparation method of carboxylated cellulose nanoparticles

InactiveCN105884908AThe process is simple and easy to operateImprove preparation efficiencyNanotechnologyFreeze dryOxidizing acid

The invention relates to a preparation method of carboxylated cellulose nanoparticles. The preparation method comprises the following steps of soaking a cellulose raw material in a reaction liquid; carrying out hydrothermal reaction for 0.5-6 hours at the temperature of 80-120 DEG C; diluting a reaction product with water; carrying out suction filtration and washing repeatedly until washing liquor is neutral; and carrying out freeze drying to obtain the carboxylated cellulose nanoparticles, wherein the reaction liquid is mixed liquid of an oxidizing substance aqueous solution and a hydrochloric acid aqueous solution, and oxidizing substances are at least one of oxidizing acid and oxidizing salt. The method is simple and convenient in technology, easy to operate, low in cost and short in treatment time; the product is not required to be subjected to troublesome aftertreatment such as dialysis, and the prepared cellulose nanoparticles are high in purity, narrow in size distribution and easy to regulate and control; and the carboxylated cellulose nanoparticles are suitable for industrial large-scale production, and have wide application prospect in the fields of green nano composite materials, biological medicines, food, garments, cosmetics, coating, photoelectricity and the like.

Owner:DONGHUA UNIV

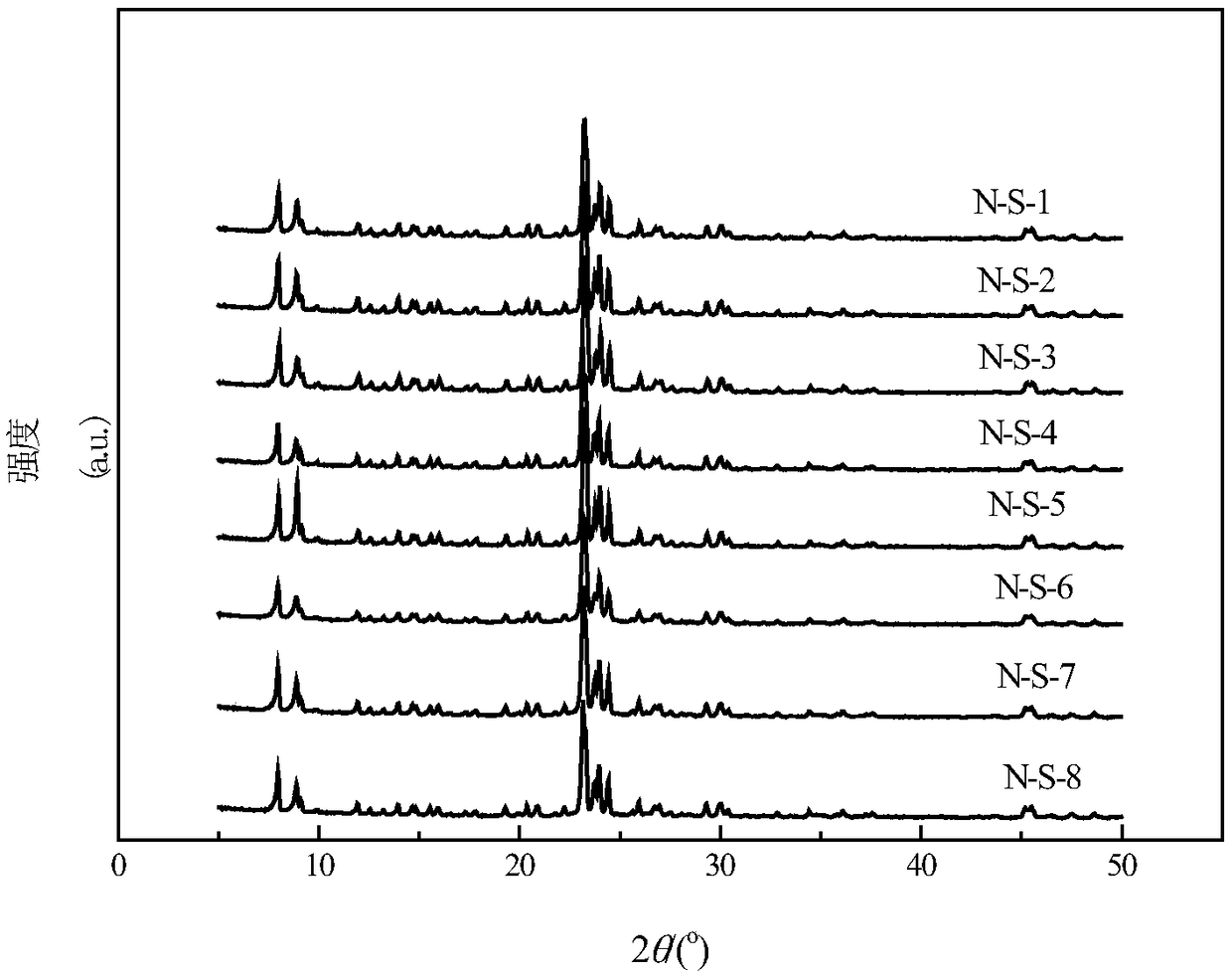

Preparation method of nano Silicalite-1 molecular sieve

InactiveCN109368654AThe process is simple and easy to operateReduce dosageSilicaMolecular-sieve silica-polymorphsMolecular sieveCrystallite

The invention discloses a preparation method of a nano Silicalite-1 molecular sieve. The molecular sieve is provided with an MFI topological structure, and the grain size of the molecular sieve can beregulated and controlled within a wide nanometer range. Through aA synthesis method of the nano Silicalite-1 molecular sieve, is used for preparing the nano Silicalite-1 molecular sieve is prepared by utilizing spherical mesoporous silica as a precursor through a steam-assisted crystallization method. and with spherical mesoporous silica as a precursor. Compared with the prior art, the synthesismethod is simple and feasible, the synthesized molecular sieve is high in crystal crystallinity, and the grain size of the molecular sieve is uniform and can be regulated and controlled within the wide nanometer range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing m-phenylenediamine by taking meta-position oil as raw material

ActiveCN110105220AThe process is simple and easy to operateCost greenOrganic compound preparationAmino compound preparationSolvent4-Nitrochlorobenzene

The invention discloses a method for preparing m-phenylenediamine by taking nitrochlorobenzene meta-position oil as a raw material. The method comprises the following steps of (1) nitrification of thenitrochlorobenzene meta-position oil, wherein the nitrochlorobenzene meta-position oil is added into concentrated sulfuric acid, the temperature rises, fuming nitric acid is added dropwise, a reaction is carried out, standing is carried out for removing waste acid, and a mixture of 2,4-nitrochlorobenzene and 3,5-dinitrochlorobenzene is obtained; (2) a catalytic hydrogenation reaction, wherein themixture of the 2,4-nitrochlorobenzene and the 3,5-dinitrochlorobenzene is taken as a raw material, methyl alcohol is taken as a solvent, an alkaline substance is taken as an acid-binding agent, precious metal palladium carbon is taken as a catalyst, hydrogen is introduced, and the m-phenylenediamine is obtained. The novel method for treating the nitrochlorobenzene meta-position oil is found, which can turn waste into wealth; compared with other methods for treating the meta-position oil, the method is simple and direct, and meets the requirement of the atomic economic benefit; other unnecessary side reactions cannot be generated, and the process is simple and easy to operate; compared with a method for preparing the m-phenylenediamine through the reduction of m-dinitrobenzene, the methodis more environmentally friendly, and low in cost.

Owner:济宁市金泰利华化工科技有限公司

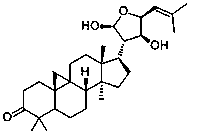

Preparation method of sliver-white aglaione A

InactiveCN103450315AThe process is simple and easy to operateHigh product puritySteroidsSolventChemistry

The invention discloses a preparation method of sliver-white aglaione. The preparation method comprises the following steps of drying and crushing sliver-white aglaia odorata leaves, adding 50%-99% ethanol liquor which is 5-10 times the amount of the sliver-white aglaia odorata leaves; carrying out reflux extraction for 2-3 times, concentrating extracting liquor until the liquor has no alcohol; adding into a macroporous resin for adsorption; carrying out gradient elution with the ethanol liquor, recycling a solvent from the eluant, placing for precipitating, and filtering out the precipitates for heating and dissolving by using 90%-95% ethanol; adding an appropriate amount of water until the alcohol concentration is 40%-70%; adding isopyknic petroleum ether for sufficiently stirring, collecting a petroleum ether layer for suction filtration; collecting a filter cake and dissolving and crystallizing 2-3 times using the ethanol liquor, and drying to obtain the sliver-white aglaione A. The preparation method of the sliver-white aglaione A is simple and convenient in process operation, and easily realizes industrial production.

Owner:NANJING TONGZE AGRI SCI & TECH

Reinforcing construction technology for carbon fibers

InactiveCN102345262AThe process is simple and easy to operateQuality assurancePaving reinforcementsAssurance qualityFiber

The invention discloses a reinforcing construction technology for carbon fibers; the reinforcing construction technology comprises steps of positioning pay-off, processing surfaces of concrete members, coating bottom-layer resin, preparing and painting dipping resin, pasting carbon fiber sheets, surface protection, nursing and testing. The technology of the invention is simple and convenient to operate, ensures the quality, and is safe and environmental-friendly.

Owner:BORUISI TECH DALIAN

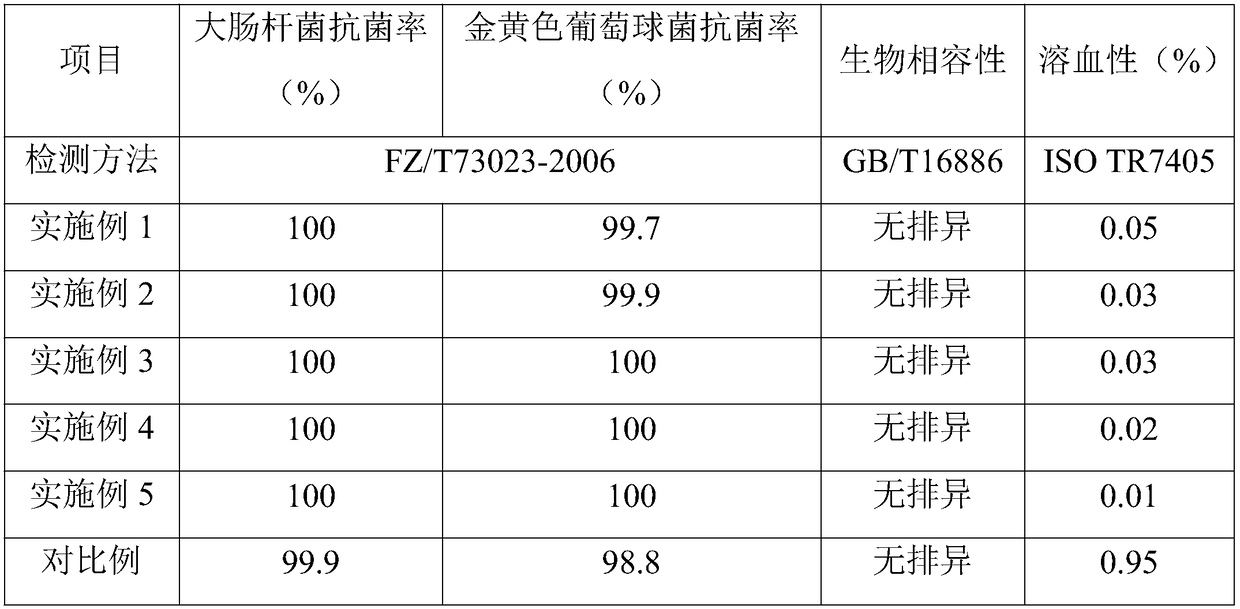

Antibacterial agent for suture line of surgical operation and preparation method of antibacterial agent

InactiveCN109248334AThe process is simple and easy to operateDevice dependency is smallSuture equipmentsAntibacterial effectEnvironmentally friendly

The invention discloses a preparation method of an antibacterial agent for a suture line of surgical operation. The preparation method comprises the following steps: (1) preparing a chloro silver lactate compound; (2) preparing chitosan modified by 5-(4-chlorobutyl) hydantoin; and (3) doping silver ions. The invention further discloses the antibacterial agent for the suture line of surgical operation which is prepared by adopting the preparation method and the suture line of the surgical operation which adopts the antibacterial agent for the suture line of surgical operation as the antibacterial treatment agent. The antibacterial agent for the suture line of surgical operation disclosed by the invention is low in preparation price, obvious in antibacterial effect, good in compatibility with the suture line of the surgical operation, good in stability of the antibacterial property, and safe and environmentally friendly in use.

Owner:湖南博隽生物医药有限公司

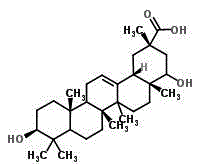

Purification method of maytenfolic acid

InactiveCN104945462AThe process is simple and easy to operateHigh product puritySugar derivativesSteroidsCounter currentSolvent

The invention discloses a purification method of maytenfolic acid. The method comprises the following steps: pulverizing a dry Euonymus raw material, screening, adding an enzymolysis water solution, carrying out enzymolysis under acidic conditions for 1-3 hours, after the enzymolysis finishes, adding a extraction solvent, carrying out ultrasonic extraction, filtering, extracting the filter residue 1-3 times, merging the extracting solutions, concentrating under reduced pressure until no alcohol smell, eluting the concentrated solution through a macroporous adsorbent resin column, collecting the eluate, purifying high-speed counter-current chromatography, collecting the target component according to the spectrum, recovering the reagent, and carrying out freeze-drying to obtain the maytenfolic acid. The method for maytenfolic acid is simple in technical operation and low in cost, and can easily implement industrial production.

Owner:NANJING ZELANG MEDICAL TECH

Virus inactivation washing-free foam type disinfectant

PendingCN112546034ASimple processThe process is simple and easy to operateHydroxy compound active ingredientsAntiviralsChemistryDisinfectant

The invention discloses a virus inactivation washing-free foam type disinfectant. The virus inactivation washing-free foam type disinfectant consists of the following components in percentage by massof 0.1-0.2 percent of composite quaternary ammonium salt, 0.02-0.5 percent of synergist, 0.1-5 percent of nonionic surfactant, 0-1 percent of pH regulator and the balance of water, wherein the composite quaternary ammonium salt is a mixture of didecyl dimethyl ammonium chloride, dioctyl dimethyl ammonium chloride, dodecyl dimethyl benzyl ammonium chloride and hexadecyl dimethyl benzyl ammonium chloride. The virus inactivation washing-free foam type disinfectant is relatively high in virus inactivation capacity, and after the disinfectant acts for 1.5 minutes, the virus inactivation logarithm values of poliovirus I type vaccine strains are all larger than 4.00, that is, the inactivation rate is 99.99%; and the disinfectant is non-irritant and can be applied to parts such as hands, skin, wound surfaces and mucous membranes.

Owner:上海海禾医疗科技有限公司

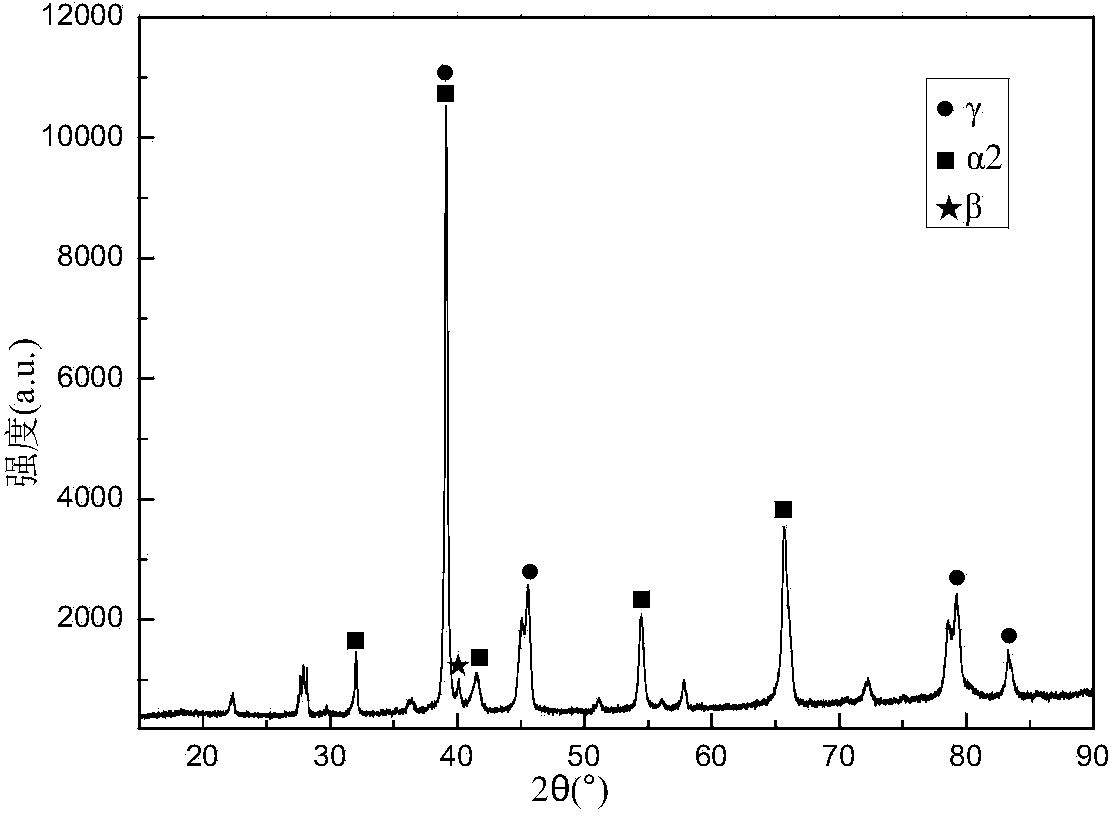

W and V alloying beta phase solidifying high Nb-TiAl alloy and preparation method thereof

The invention relates to a W and V alloying beta phase solidifying high Nb-TiAl alloy and a preparation method thereof, and belongs to the field of alloy technology. The alloy comprises the following elements by mole: 43%-45% of Al, 5%-15% of Nb, less than or equal to 0.4% of W, less than or equal to 0.5% of V, and the balance of Ti and inevitable impurities. The preparation method comprises the following steps: raw materials are subjected to briquetting forming according to constitutions, titanium sponges are placed on the edge of the inner side of a mould firstly, a high purity aluminium layer, an aluminium niobium intermediate alloy layer, an aluminium vanadium intermediated alloy layer, an aluminium tungsten niobium intermediate alloy layer and a titanium sponge layer are arranged from bottom to top respectively; pressing cakes are placed into a water-cooling copper crucible vacuum induction suspension smelting furnace capable of centrifugal pressure casting for vacuum smelting to obtain melts and the melts are enabled to be mixed uniformly; the melts are cast in a metal casting mould that is preheated in advance and centrifugally rotates for centrifugal rotating and casting and cooled with the furnace. According to the invention, a TiAl alloy that is homogeneous and fine in structure and has no obvious segregation is obtained.

Owner:BEIJING UNIV OF TECH

Low-alcohol red beer

InactiveCN103710190AThe process is simple and easy to operateSoft tasteBeer brewingChemistryCitric acid

The invention provides a low-alcohol red beer. The low-alcohol red beer per kiloliter is prepared from the following raw materials: 830-840L of water, 140-150L of 10-degree P beer fermentation liquor, 60-70Kg of white granulated sugar, 2-2.5Kg of caramel pigment, 55-65g of essence and 0.8-1.2Kg of citric acid. The low-alcohol red beer is directly prepared from the 10-degree P beer fermentation liquor obtained by the existing conventional process and other raw materials; the process of producing the low-alcohol red beer is simple and easy to operate; the obtained red beer is soft in taste and outstanding in fragrance; the alcohol content of the obtained red beer is below 2.5%(v / v).

Owner:YANJING BEER GUILIN LIQUAN

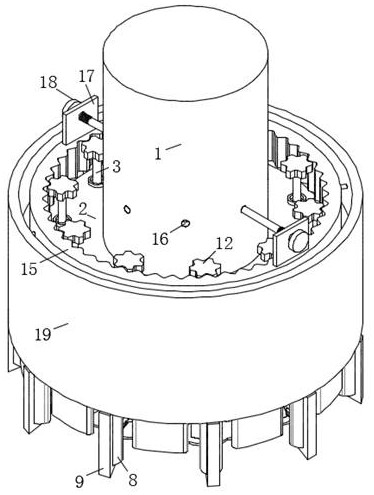

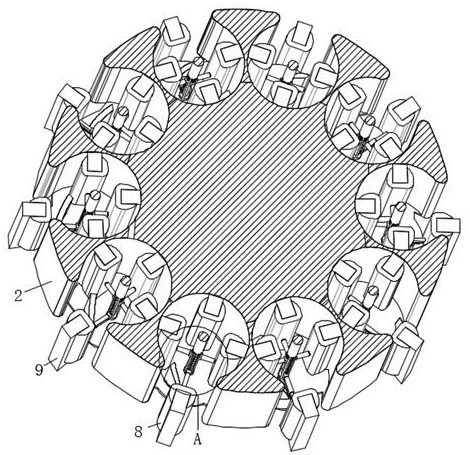

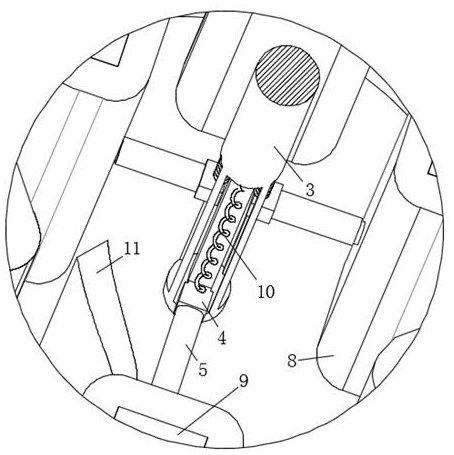

Milling cutter assembly for precision machining

PendingCN114734081AThe process is simple and easy to operateQuick switchMilling cuttersPush outStructural engineering

The invention relates to the technical field of machine tool machining, and particularly discloses a milling cutter assembly for precision machining. The milling cutter assembly comprises an output shaft, the bottom of the output shaft is fixedly connected with a circular plate, circular cavities are formed in the circular plate at equal intervals in a surrounding mode, openings communicated with the circular cavities are formed in the outer side of the circular plate, a rotating rod is vertically and rotationally installed in the middle of the circular cavities, sliding grooves are formed in the outer side of the rotating rod at equal intervals in a surrounding mode, and sliding blocks are slidably installed in the sliding grooves. Milling cutters with different hardness can be rapidly switched, the requirement for machining workpieces with different hardness can be met, the whole process is simple and easy to operate, time and labor are saved, a mounting frame for mounting the milling cutters can be pushed while the milling cutters are switched, the milling cutters can be pushed out of an opening, and the machining efficiency is improved. And under the condition that the first spring fails due to long-term use and cannot be normally used, normal push-out of the mounting frame can still be ensured, then normal switching is ensured, and the device is worthy of popularization and use.

Owner:常州博胜天泓工具有限公司

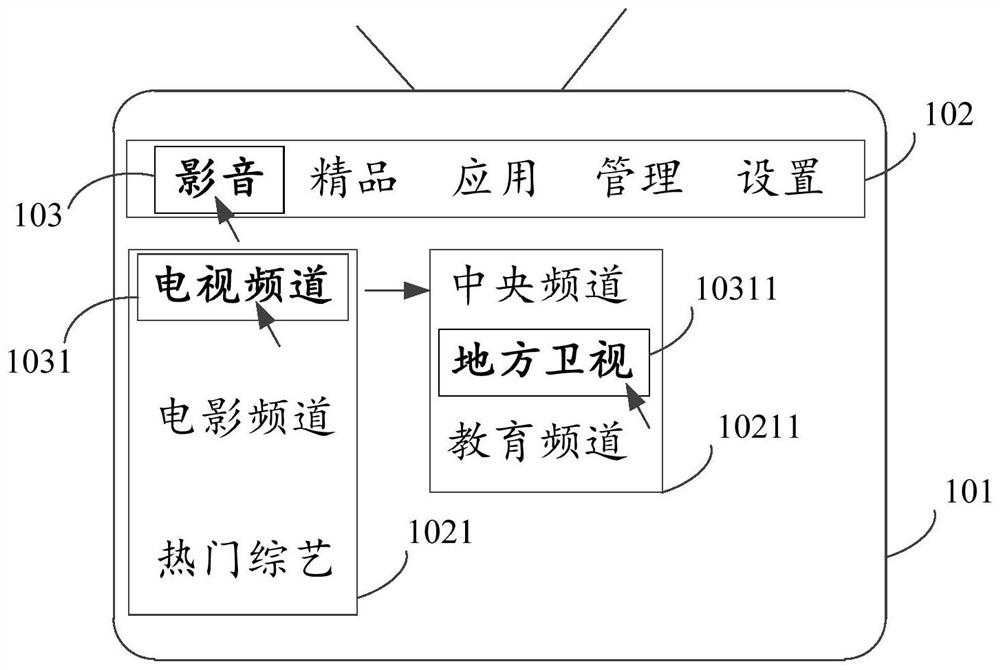

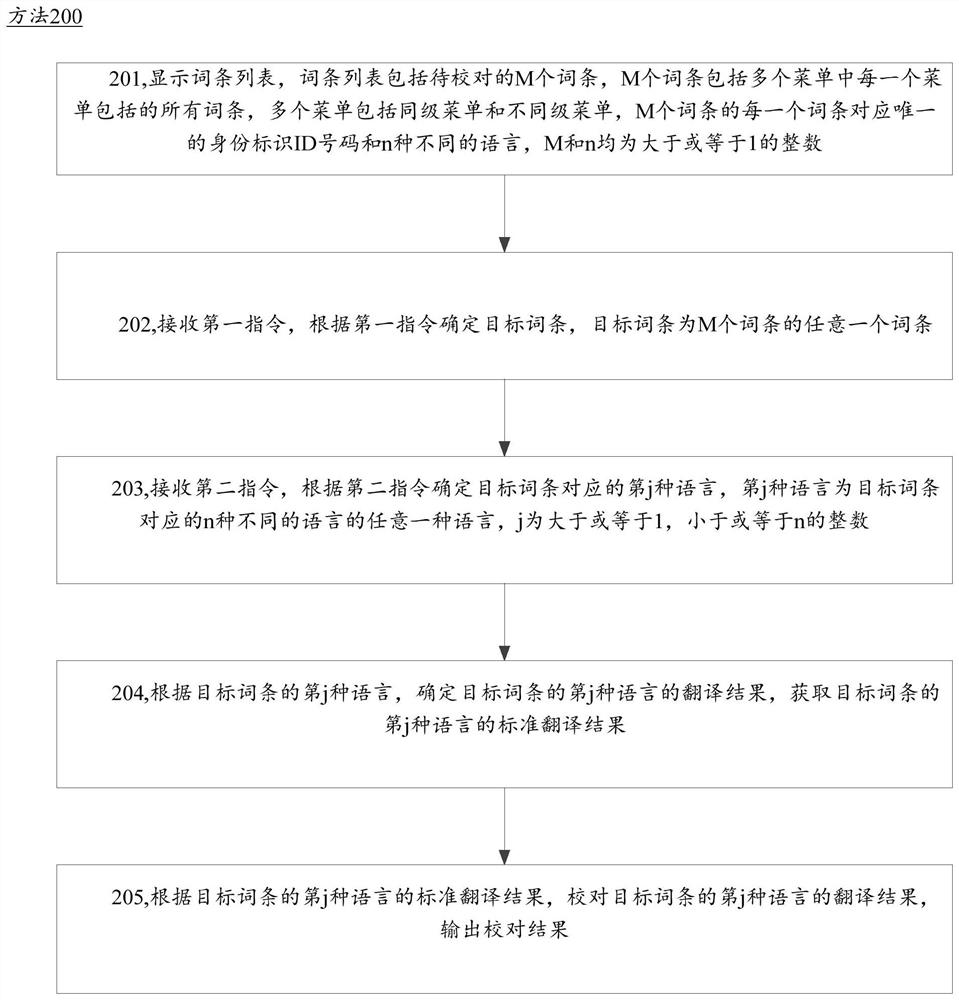

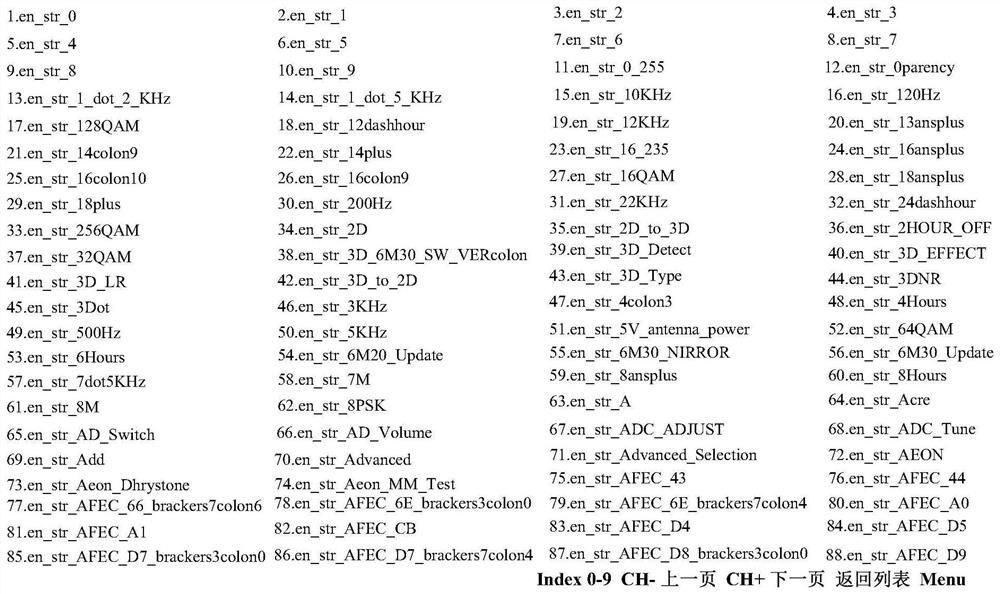

Method and device for proofreading entry translation result and storage medium

PendingCN114492472AThe process is simple and easy to operateSimple stepsNatural language translationMaterial resourcesProgramming language

The invention provides a method and device for proofreading an entry translation result and a storage medium, and the method comprises the steps: displaying an entry list, the entry list comprises M to-be-proofreading entries, and each entry of the M entries corresponds to a unique identity identification ID number and n different languages; receiving a first instruction, and determining a target entry according to the first instruction; a second instruction is received, the jth language corresponding to the target entry is determined according to the second instruction, and the jth language is any one of n different languages corresponding to the target entry; according to the jth language of the target entry, determining a translation result of the jth language of the target entry, and obtaining a standard translation result of the jth language of the target entry; and according to the standard translation result of the jth language of the target entry, proofreading the translation result of the jth language of the target entry, and outputting a proofreading result. According to the method, entry translation can be simply, efficiently and quickly proofread, and manpower and material resources are saved.

Owner:东莞市金锐显数码科技有限公司

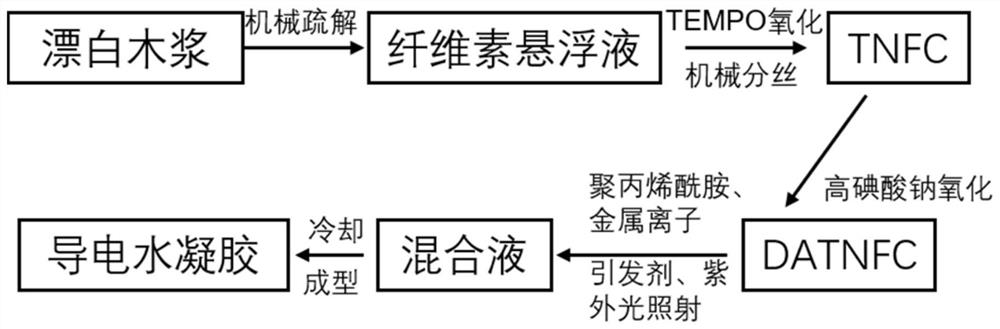

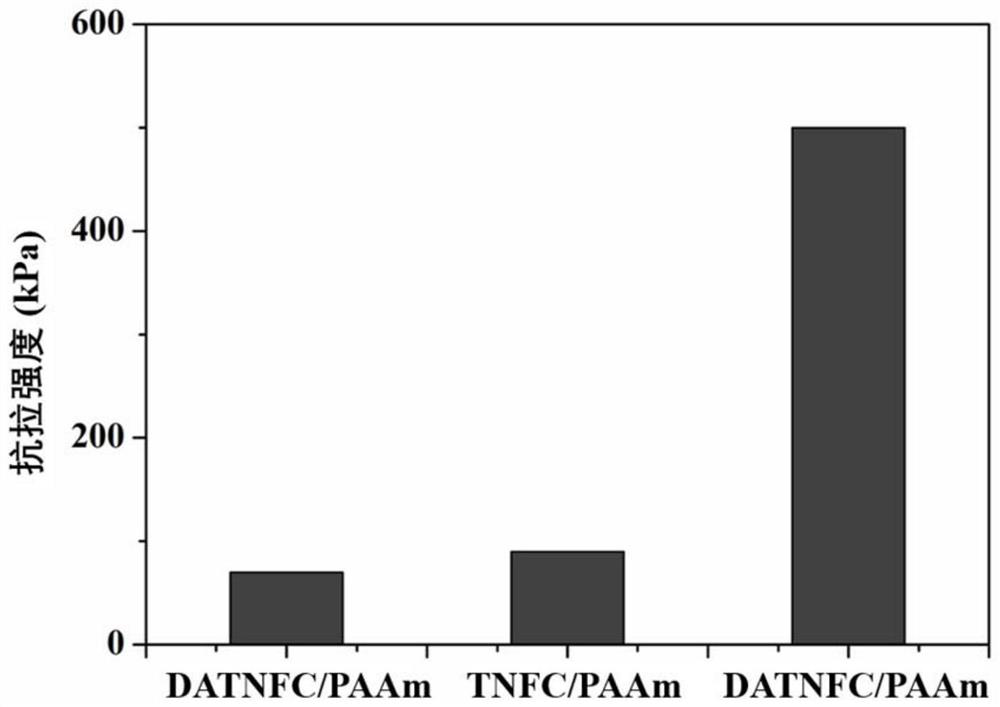

Conductive hydrogel based on nanocellulose-polyacrylamide-metal ions as well as preparation method and application of conductive hydrogel

PendingCN114479118AThe process is simple and easy to operateGood self-healing propertiesConverting sensor outputChemistryPhotoinitiator

The invention discloses conductive hydrogel based on nanocellulose-polyacrylamide-metal ions as well as a preparation method and application of the conductive hydrogel. The method comprises the following steps: (1) pretreating sufficiently defibered cellulose slurry by adopting TEMPO oxidation to obtain TEMPO-nano cellulose; then adding sodium periodate into the TEMPO-nano cellulose, and carrying out a reaction in a dark place to obtain DATNFC-TNFC containing carboxyl groups and aldehyde groups; and (2) uniformly mixing the DATNFC-TNFC containing carboxyl and aldehyde group, polyacrylamide and metal ions under heating and stirring conditions, then adding a photoinitiator, carrying out a reaction under ultraviolet irradiation, and after the reaction is finished, carrying out cooling molding to obtain the conductive hydrogel. The conductive hydrogel prepared by the method has excellent self-healing performance, mechanical performance and sensing performance, and can be used for wearable sensor devices.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com