Chitosan/in-situ amphoteric silicon-titanium hybrid film as well as preparation method and application thereof

A chitosan and amphoteric technology, which is applied in the field of chitosan/in-situ amphoteric silicon-titanium hybrid membrane and its preparation, can solve the problem of proton exchange membrane that has not been reported in literature, and achieves prevention of agglomeration and low methanol permeability. , The process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

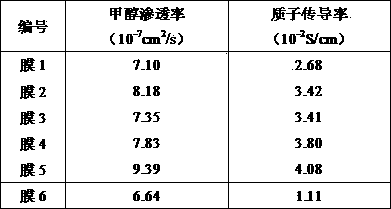

Embodiment 1

[0018] Weigh 1 g molecular weight as 6×10 5 , Chitosan with a degree of deacetylation of 91% was dissolved in 25 g of acetic acid aqueous solution with a mass concentration of 2%, at 70 oC Complete dissolution with stirring. At room temperature, 0.0355 g of ethyl orthosilicate was added to 5 g of aqueous hydrochloric acid with a mass concentration of 7%, and hydrolyzed at 45 °C for 2 h. 0.0323 g of titanium tetrachloride was added to 5 g of 20% ethanol aqueous solution, and hydrolyzed at room temperature for 2 h. The two were mixed and the reaction was stirred at room temperature for 3 h. Then, 0.0032 g of 3,4-dihydroxyphenylpropionic acid was added, and the mixture was chelated at room temperature for 1 h. Continue to add 0.0037g of 3-aminopropyltrimethoxysiloxane to react in a water bath at 60°C for 4h to obtain a brown-red amphoteric inorganic silicon-titanium sol solution. The brown-red amphoteric inorganic silicon-titanium sol solution was slowly added to the chitosa...

Embodiment 2

[0020] Weigh 1 g molecular weight as 6×10 5 , Chitosan with a degree of deacetylation of 91% was dissolved in 50 g of acetic acid aqueous solution with a mass concentration of 2%, at 75 oC Complete dissolution with stirring. At room temperature, 0.0828 g of ethyl orthosilicate was added to 5 g of aqueous hydrochloric acid with a mass concentration of 5%, and hydrolyzed at 30 °C for 2 h. 0.0754 g of titanium tetrachloride was added to 5 g of 50% ethanol aqueous solution, and hydrolyzed at room temperature for 2 h. After mixing the two, the reaction was stirred at room temperature for 3.5 h. Then, 0.0061 g of 3,4-dihydroxyphenylpropionic acid was added, and the mixture was chelated at room temperature for 1 h. Continue to add 0.0086g of 3-aminopropyltrimethoxysiloxane to react in a water bath at 45°C for 5h to obtain a brown-red amphoteric inorganic silicon-titanium sol solution. The brown-red amphoteric inorganic silicon-titanium sol solution was slowly added to the chitos...

Embodiment 3

[0022] Weigh 1 g molecular weight as 6×10 5 , Chitosan with a degree of deacetylation of 91% was dissolved in 30g of acetic acid aqueous solution with a mass concentration of 2%, at 80 o Stir at C for complete dissolution. At room temperature, 0.0524 g of ethyl orthosilicate was added to 5 g of aqueous hydrochloric acid with a mass concentration of 5%, and hydrolyzed at 60 °C for 2 h. 0.0239 g of titanium tetrachloride was added to 5 g of 30% ethanol aqueous solution, and hydrolyzed at room temperature for 2 h. After mixing the two, the reaction was stirred at room temperature for 4 h. Then, 0.0025 g of 3,4-dihydroxyphenylpropionic acid was added, and the mixture was chelated at room temperature for 1 h. Continue to add 0.0068g of 3-aminopropyltrimethoxysiloxane and react in a water bath at 30°C for 5h to obtain a brown-red amphoteric inorganic silicon-titanium sol solution. The brown-red amphoteric inorganic silicon-titanium sol solution was slowly added to the chitosan s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com