Bismuth quantum dot and preparation method thereof

A technology of quantum dots and bismuth powder, which is applied in the field of bismuth quantum dots and its preparation, can solve the problems of low yield of flake bismuthene materials, is not suitable for commercial production, and is not easy to repeat, and achieves uniform size, low toxicity, and large size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

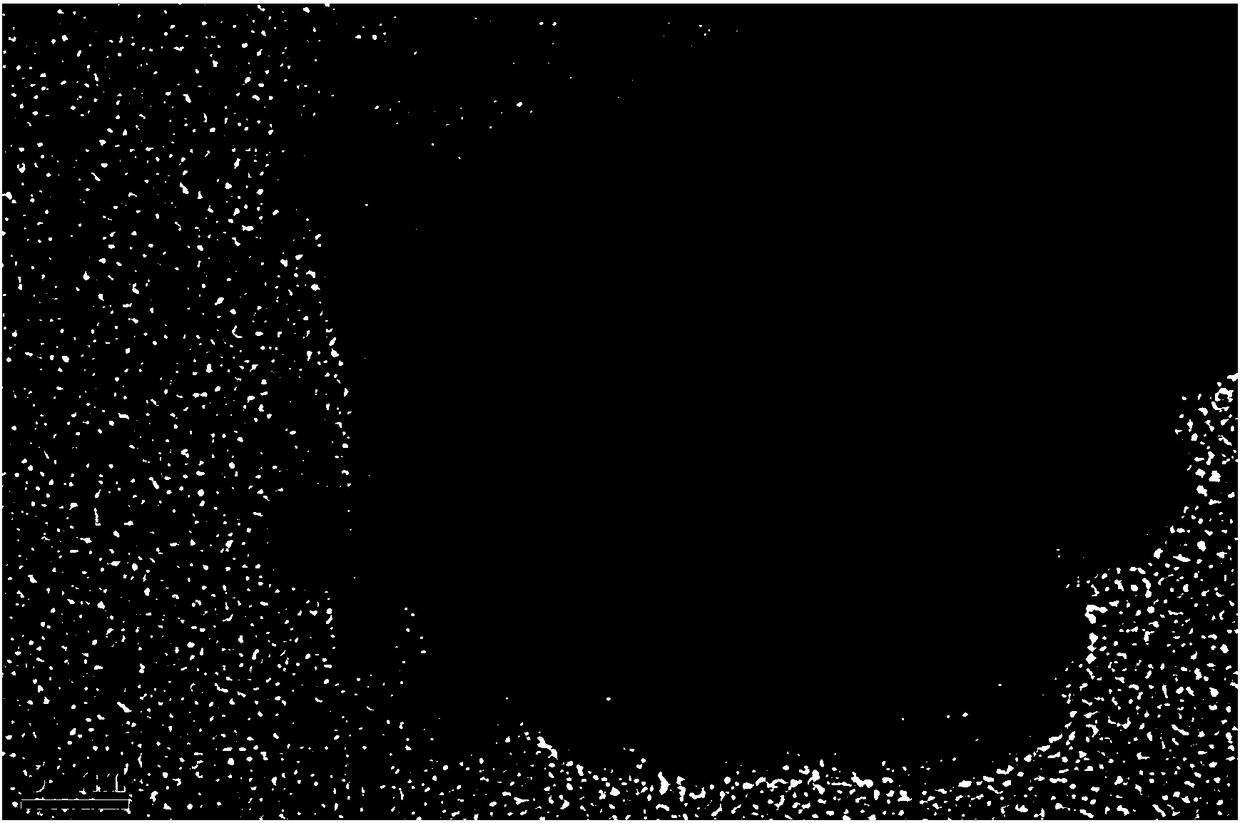

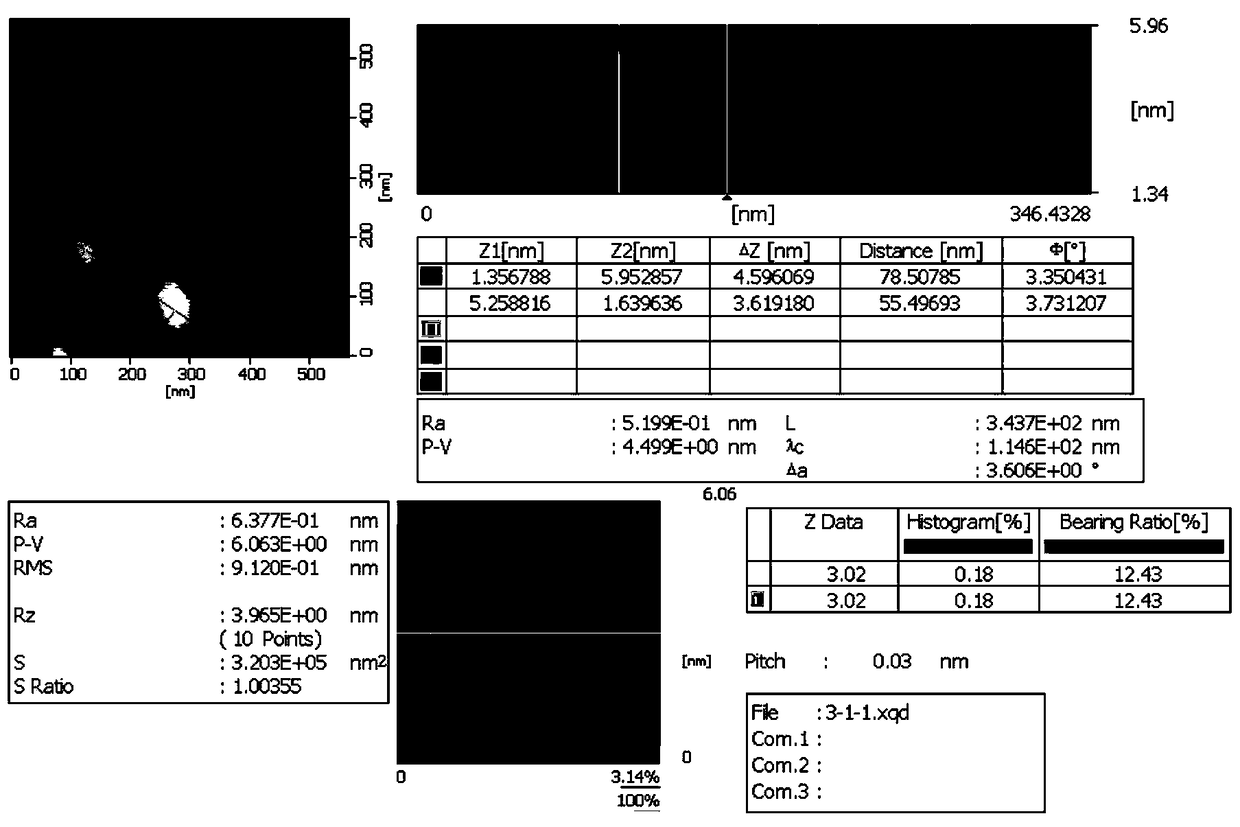

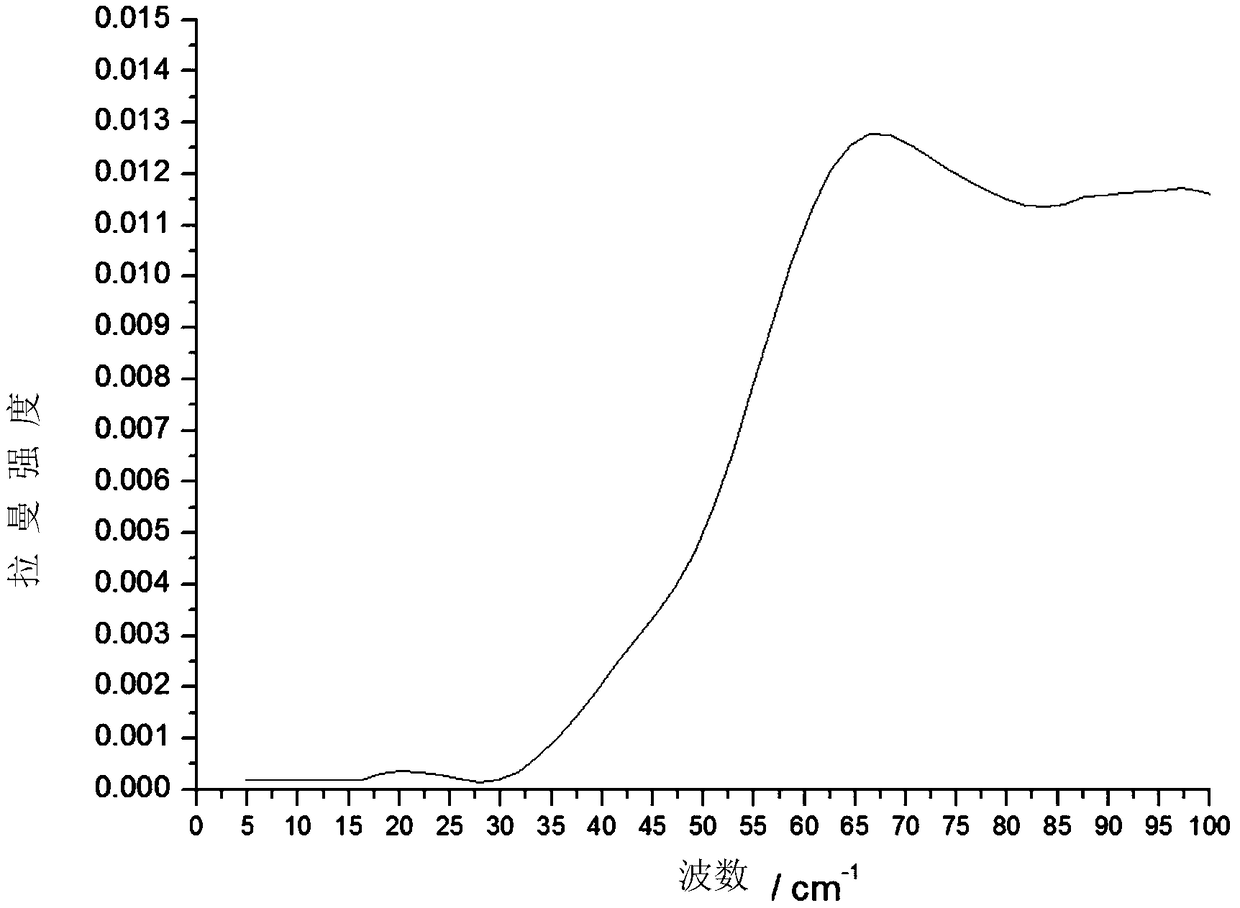

Embodiment 1

[0051] A preparation method of bismuth quantum dots, comprising the following steps:

[0052] (1) Take a Shu Niu glass bottle with a capacity of 250mL, fill it with 120mL of NMP solvent, and then add 120mg of 200 mesh (200 grains / square inch, that is, a particle size of 0.074mm) bismuth powder to obtain the initial concentration of bismuth powder 1mg / mL (or 1000ppm) dispersion;

[0053] (2) Put the glass bottle in (1) into the Xinzhi ultrasonic constant temperature cleaning machine SBL-22DT, and perform water bath ultrasonication at 70% of the maximum power (600W) (that is, with a power of 420W) at a constant temperature of 10°C for 6 hours;

[0054] After ultrasonication in a water bath, place the resulting solution in a BILON-1800Y cell disruptor (maximum power of 1800W), and perform probe ultrasonication at 4°C with a power of 60% (that is, a power of 1080W) for 24 hours to obtain the first ultrasonic wave. liquid;

[0055] Then put the first ultrasonic liquid into the Xi...

Embodiment 2

[0059] A preparation method of bismuth quantum dots, comprising the following steps:

[0060] (1) Take a Shu Niu glass bottle with a capacity of 250 mL, fill it with 120 mL of NMP solvent, and then add 120 mg of 200 mesh bismuth powder to obtain a dispersion with an initial concentration of bismuth powder of 1 mg / mL (or 1000 ppm);

[0061] (2) Put the glass bottle in (1) into Xinzhi Ultrasonic Constant Temperature Cleaner SBL-22DT, and perform water bath ultrasonication for 3 hours at a constant temperature of 10°C with 70% of the maximum power (600W) (that is, with a power of 420W);

[0062] After ultrasonication in a water bath, place the resulting solution in a BILON-1800Y cell disruptor (maximum power of 1800W), and perform probe ultrasonication at 4°C with a power of 60% (that is, a power of 1080W) for 24 hours to obtain the first ultrasonic wave. liquid;

[0063] Then put the first ultrasonic liquid into the Xinzhi ultrasonic constant temperature cleaning machine SBL-22...

Embodiment 3

[0069] A preparation method of bismuth quantum dots, comprising the following steps:

[0070] (1) Take a Shu Niu glass bottle with a capacity of 500mL, fill it with 400mL of NMP solvent, and then add 200mg of 300 mesh bismuth powder to obtain a dispersion with an initial concentration of bismuth powder of 0.5mg / mL;

[0071] (2) Put the glass bottle in (1) into Xinzhi ultrasonic constant temperature cleaning machine SBL-22DT, and perform water bath ultrasonication at a constant temperature of 4°C with a power of 480W for 2 hours;

[0072] After ultrasonication in the water bath, place the obtained solution in a BILON-1800Y cell disruptor (maximum power of 1800W), and perform probe ultrasonication with 75% power (ie, power of 1350W) for 15 hours to obtain the first ultrasonic solution;

[0073] Then put the first ultrasonic liquid into the Xinzhi ultrasonic constant temperature cleaning machine SBL-22DT, and perform the second ultrasonic bath in a water bath with a power of 450W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com