Feeding machine

A feeding machine and frame technology, applied in the direction of solid materials, packaging, packaging items, etc., can solve the problems of unsatisfactory feeding speed and feeding accuracy, slow feeding speed, etc., to reduce management and maintenance costs and avoid sticking to the warehouse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

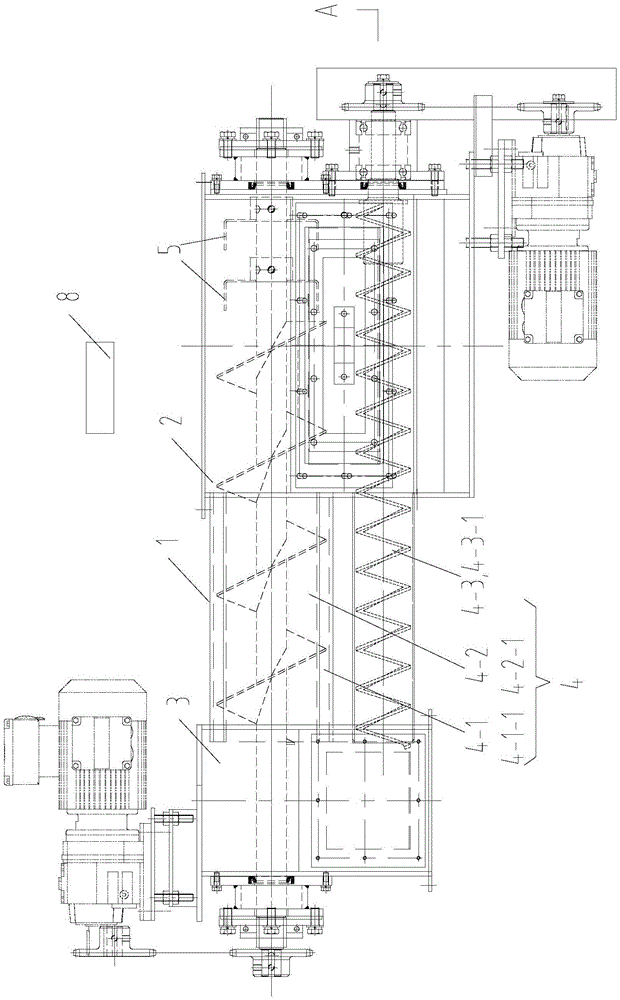

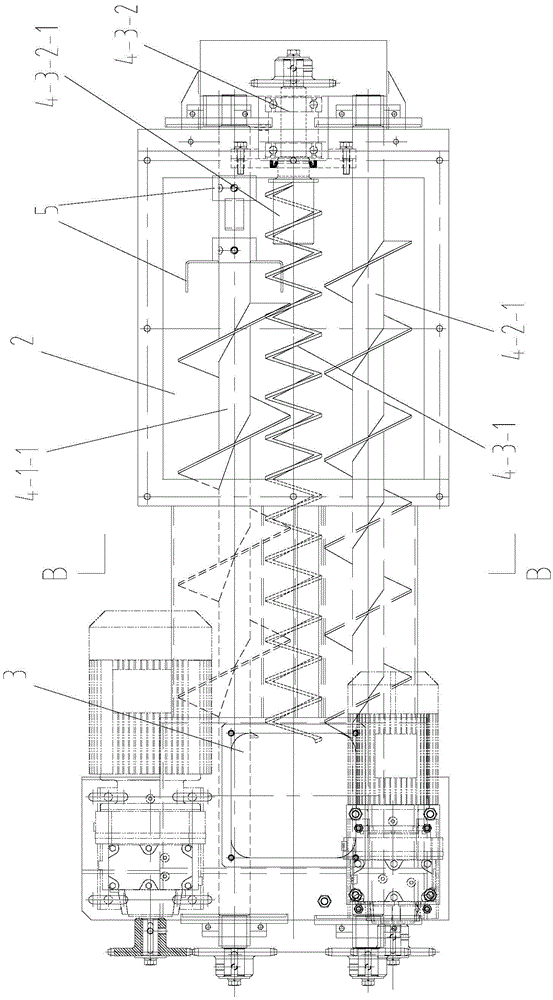

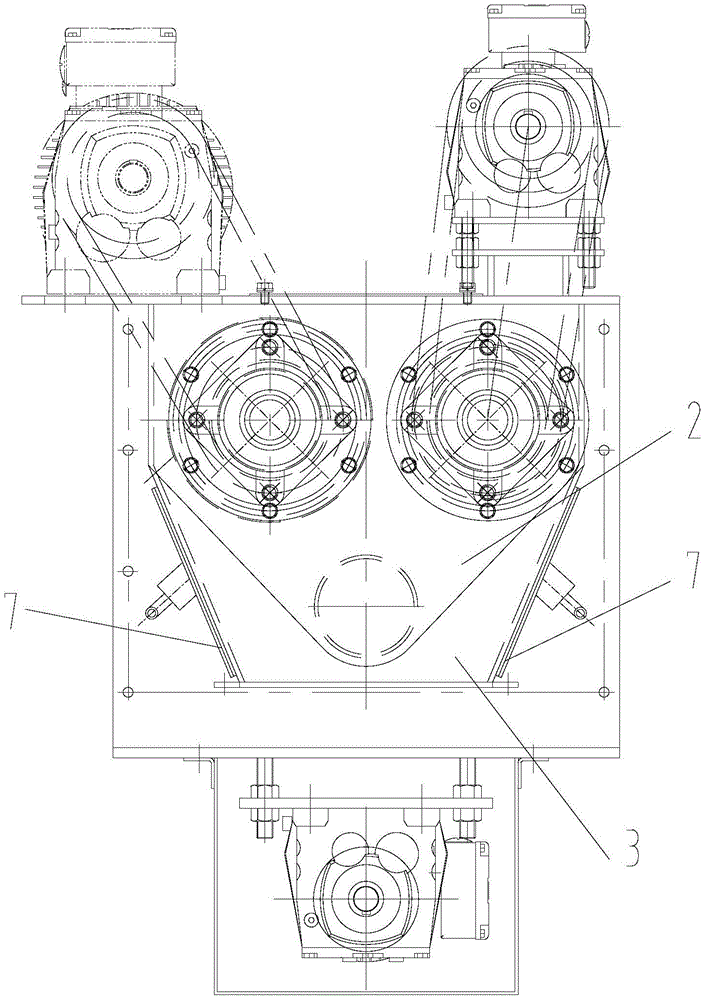

[0030] Below with reference to accompanying drawing, through the description of specific embodiment, the present invention will be further described

[0031] One of the specific implementation modes, as attached Figure 1~5 shown.

[0032] A feeder, which includes a frame 1, a storage bin 2 and a lower hopper 3 respectively connected to both ends of the frame 1, and a screw conveyor assembly 4 including a transmission device; the screw conveyor One end of the device assembly 4 is connected to the inner cavity of the lower hopper 3, and the spiral propulsion part of the other end extends into the storage bin 2, and its spiral propulsion part is in direct contact with the material stored in the storage bin 2. The transmission device included in the screw conveyor assembly 4, the material is transferred from the storage bin 2 to the lower hopper 3, and it:

[0033] a, there are 3 screw conveyor assemblies 4;

[0034] b, the three screw conveyor assemblies 4 are respectively a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com