Patents

Literature

115results about How to "Reduce management and maintenance costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer system for protecting software and method for protecting software

ActiveCN101178677AReduce consumptionSolve the problem of deletion efficiencySpecial data processing applicationsRedundant operation error correctionDistributed indexComputerized system

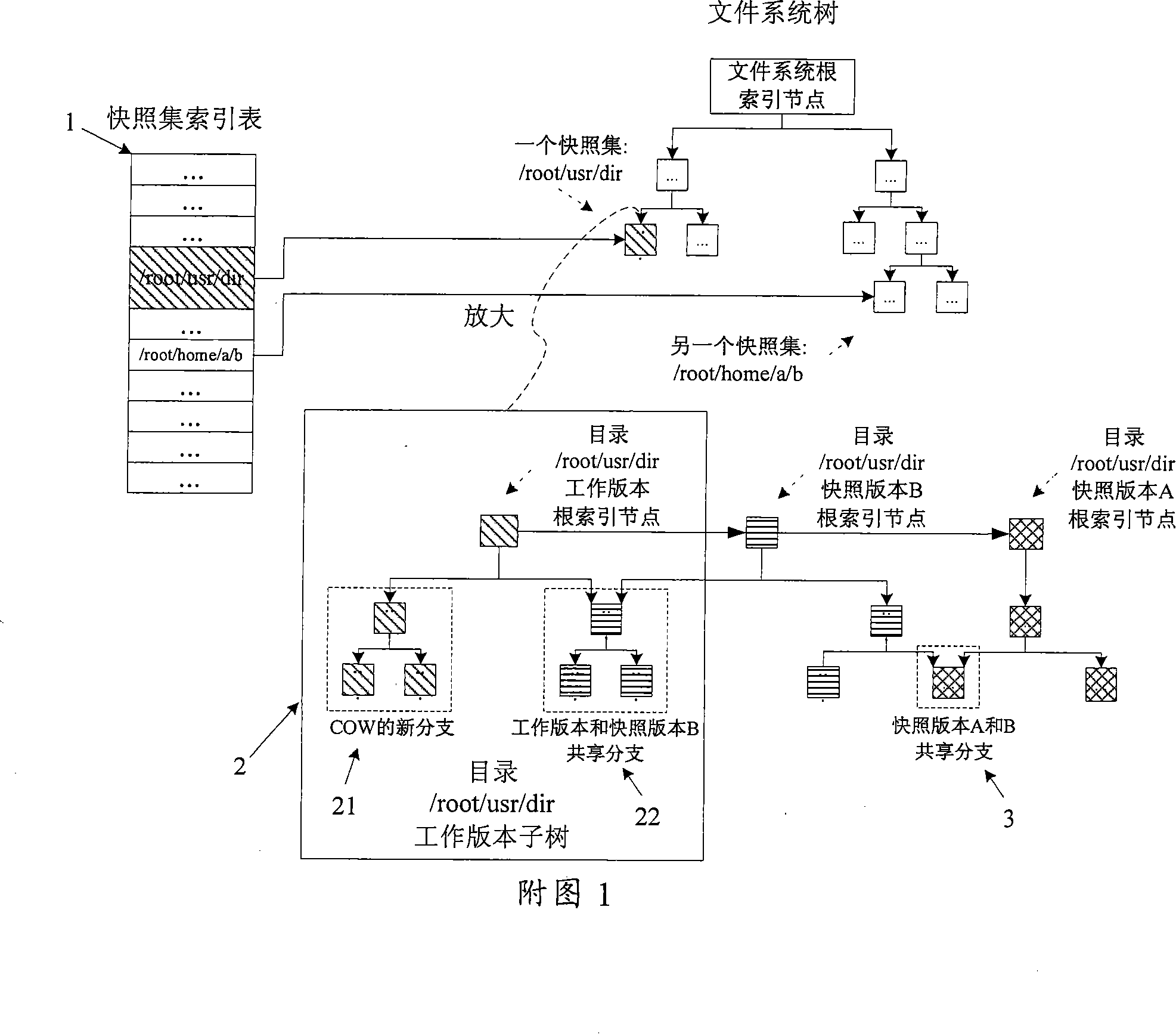

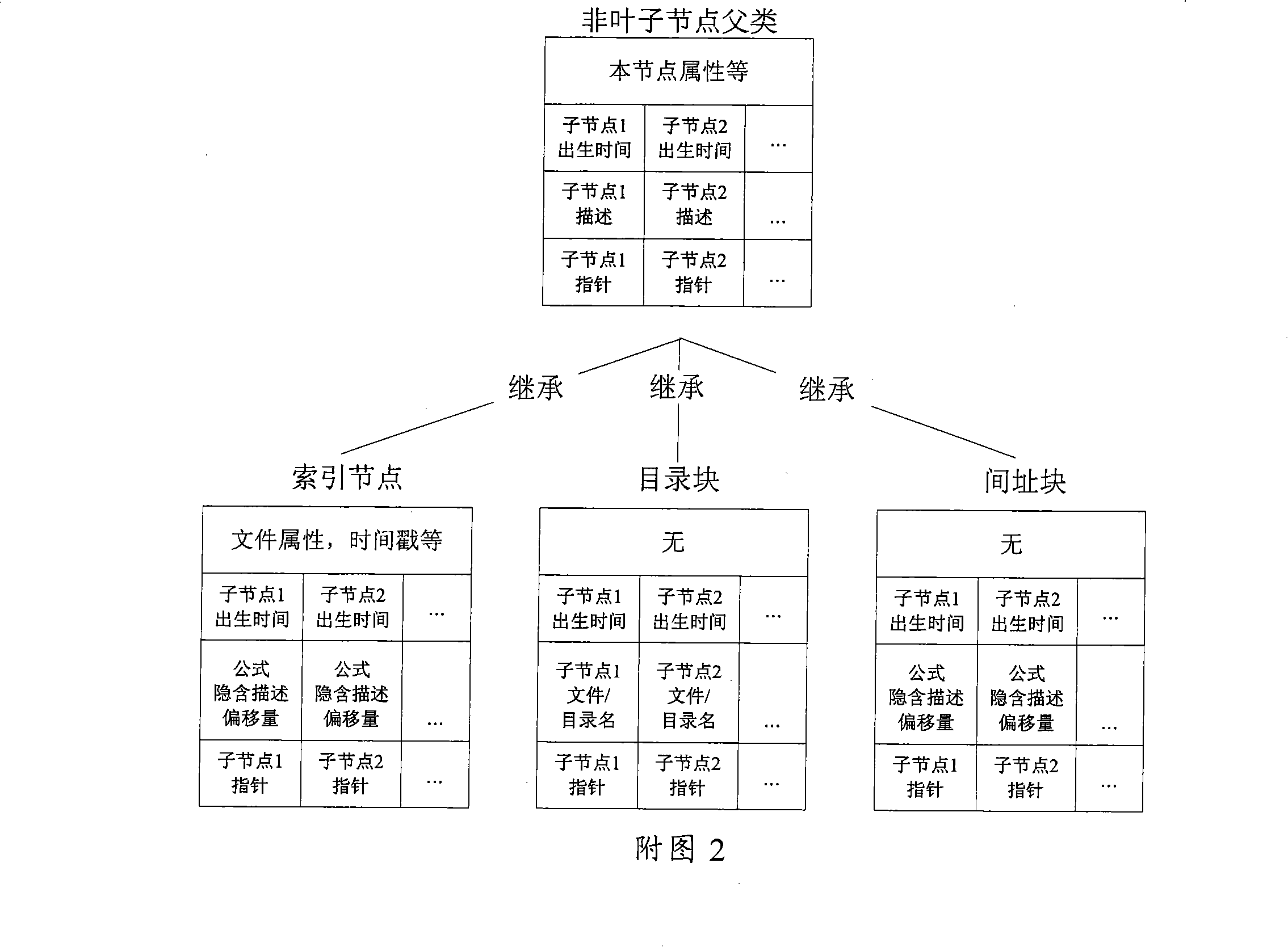

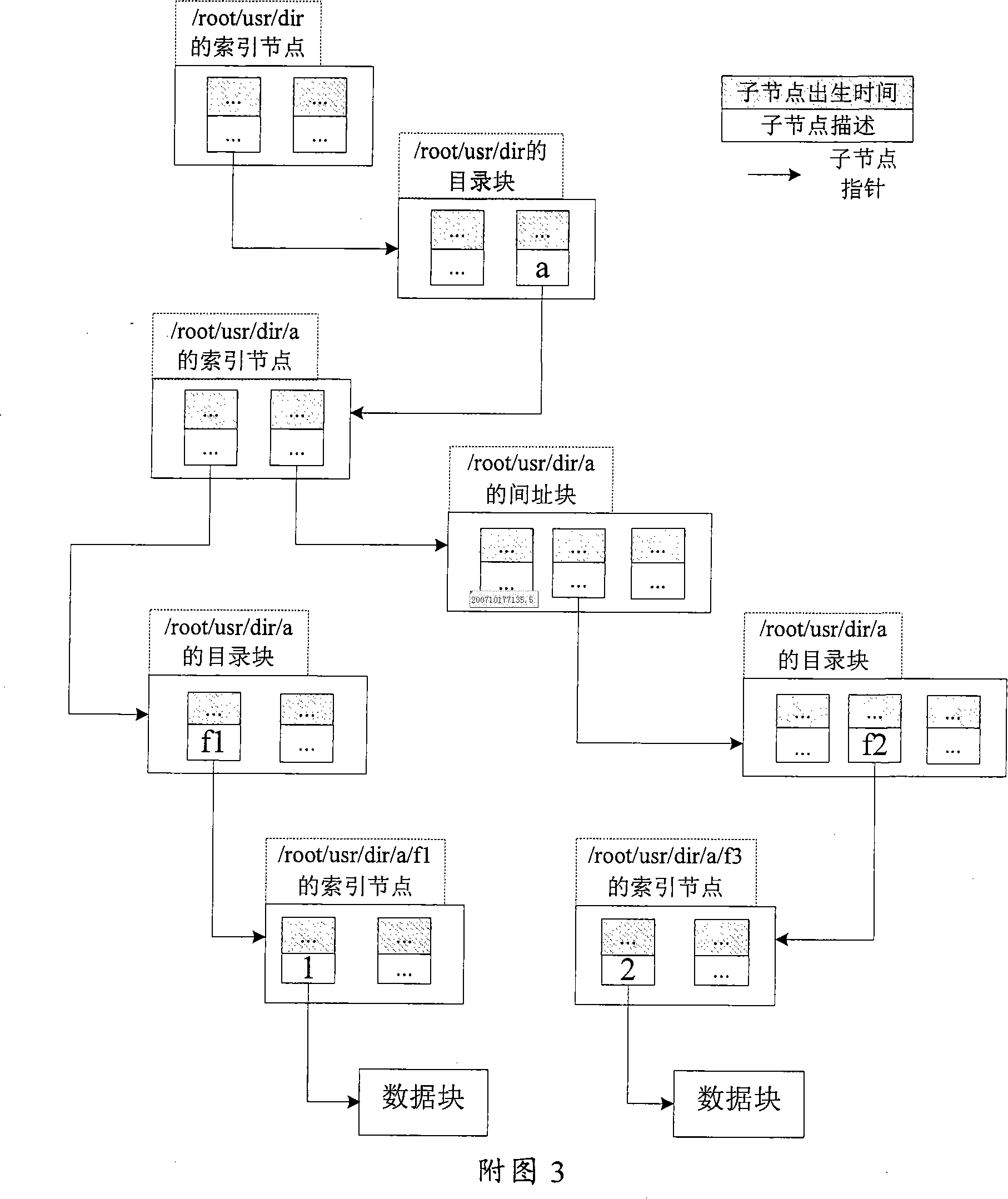

The invention provides a creating method of catalogue-grade computer file system snapshot, which comprises: the catalogue that needs to create snap is confirmed; when the catalogue creates the snap firstly, the root index node information of the catalogue work version is added to the snap index list and update the last time point of creating or deleting the snap; a new index node is distributed as the root index node of the creating snap version, and the content of the root index node of the work version is copied to the new distributed index node; the write copy chain list of the work version is copied to the root index node of the new creating snap, and then the write copy chain list content of the work version is deleted; the creating time of snap of the root index node of snap version is set as the present time of the computer system; the root index node of the snap version is linked to the snap chain list of the catalogue. The invention also provides the deleting method of the catalogue-grade computer file system snap and the modifying method of the catalogue work version.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

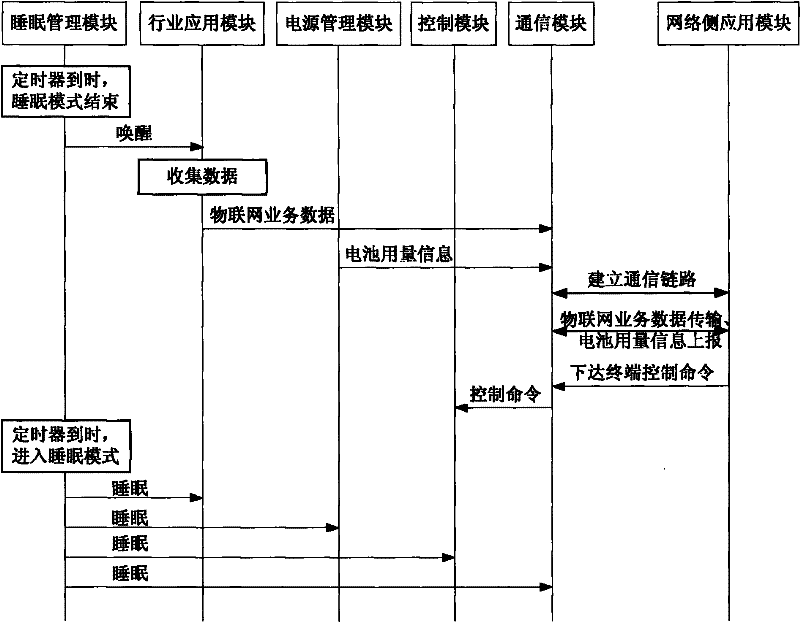

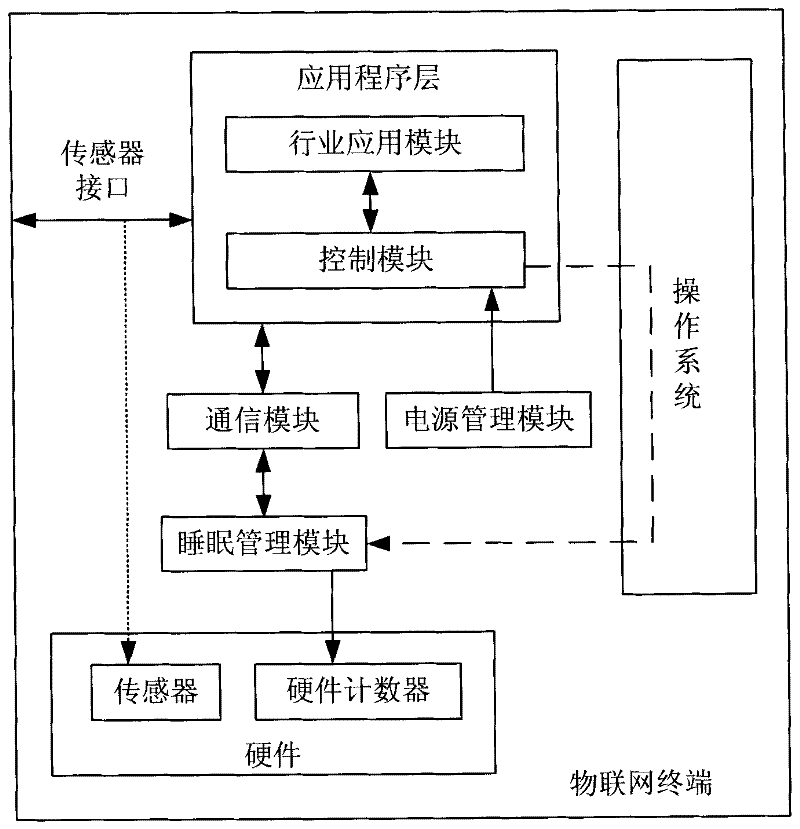

Internet of things terminal, network side equipment and system

InactiveCN102196539AReduce management and maintenance costsReduce power consumptionPower managementNetwork topologiesSleep timeSleep management

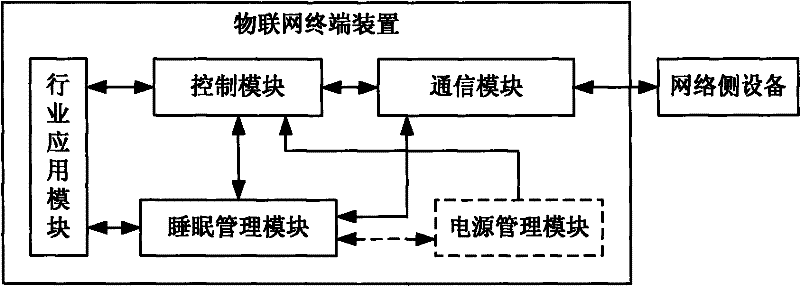

The invention discloses an Internet of things terminal, network side equipment and an Internet of things system, which have low power consumption and meet the service requirements of the Internet of things. The Internet of things terminal comprises an industry application module, a communication module, a control module and a sleep management module, wherein the industry application module is used for collecting or collecting and processing the service data of the Internet of things; the communication module is used for establishing a transmission link with a network side, transmitting the collected data or the collected and processed data to the network side, receiving a control command from the network side and transmitting the control command to the control module; the control module is used for controlling each module according to the control command transmitted by the network side; and the sleep management module is used for controlling the sleep time and awakening time of the Internet of things terminal, and at least disabling the industry application module and the communication module in the sleep time of the Internet of things terminal.

Owner:ZTE CORP

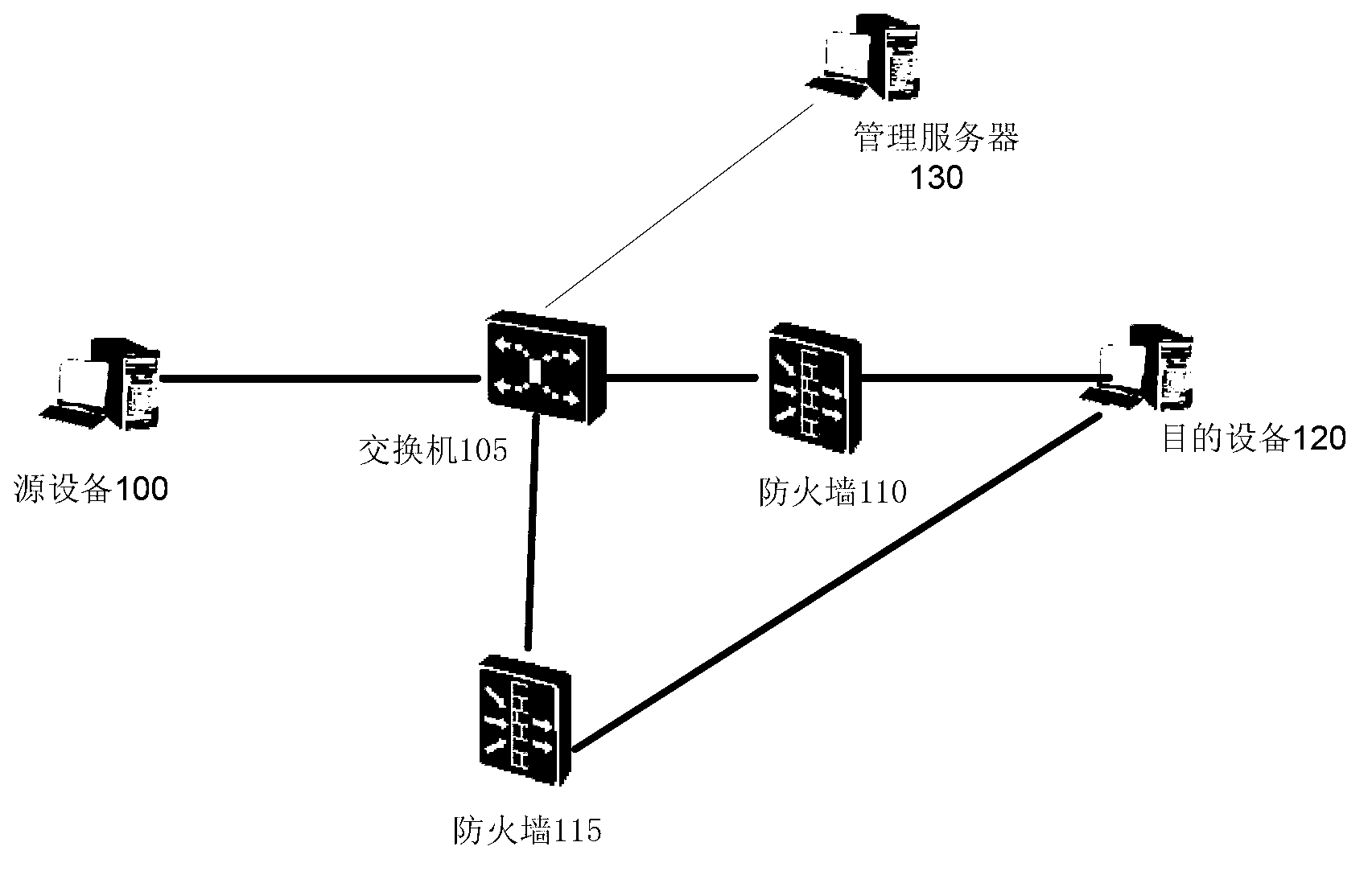

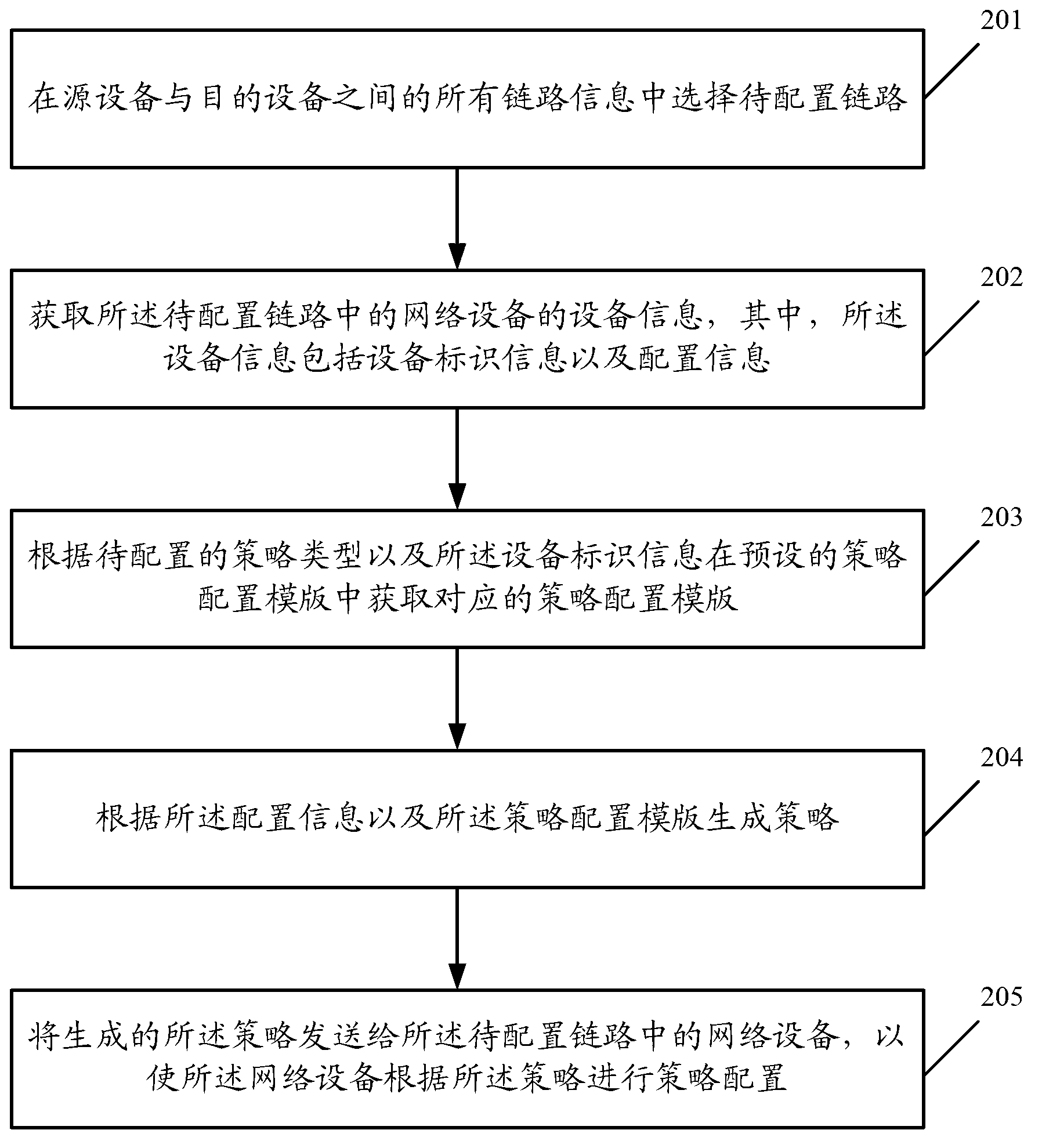

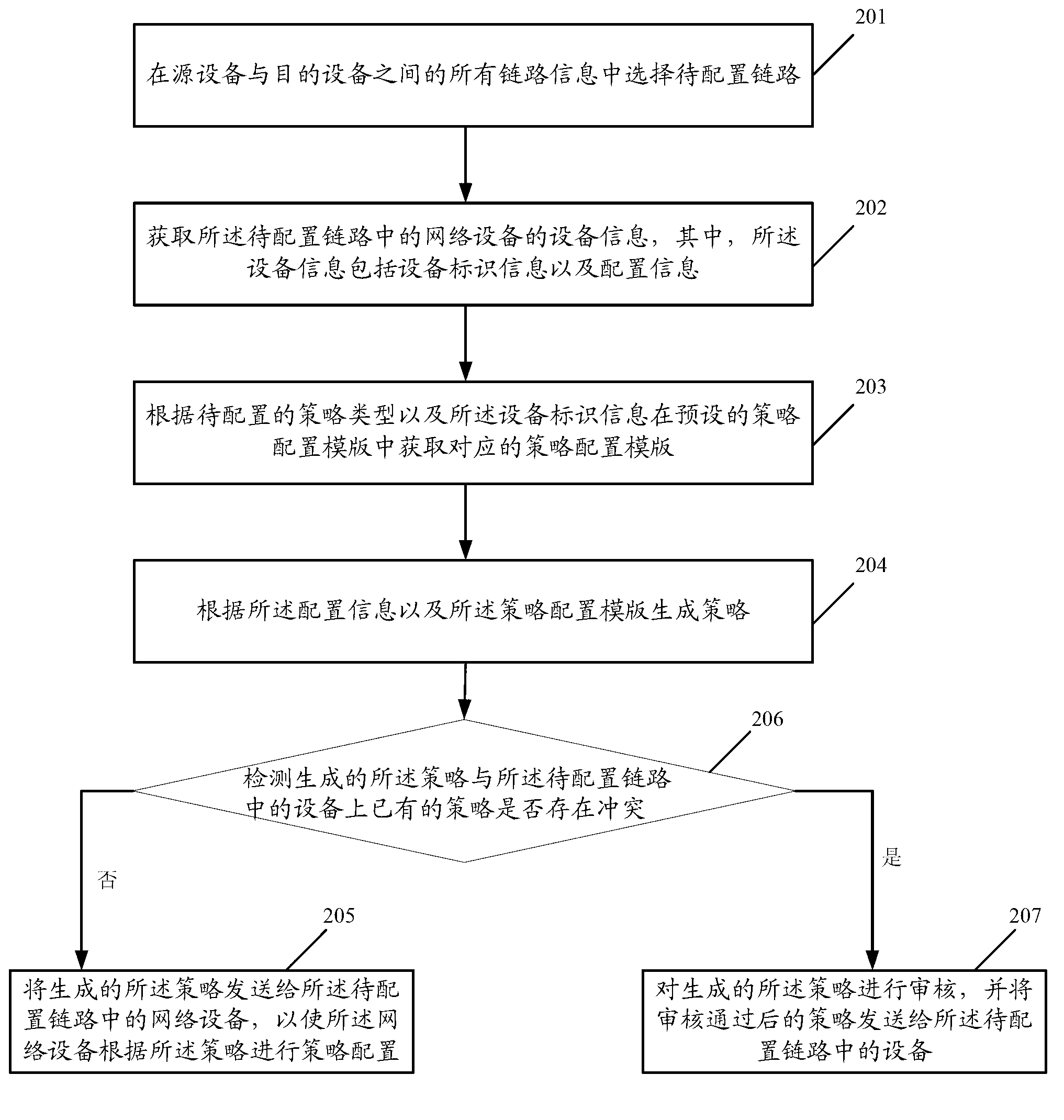

Method, managing server and network system for strategy configuration

ActiveCN103023707AImprove efficiencyReduce management and maintenance costsData switching networksDistributed computing

An embodiment of the invention discloses a method and a managing server for strategy configuration. The method includes selecting a to-be-configured link through all link information between a source device and a target device to obtain device information of a network device in the to-be-configured link so as to generate a strategy, and transmitting the strategy to the network device in the to-be-configured link to allow the network device to perform strategy configuration according to the strategy. Accordingly the problem of large management and maintenance work load caused by the fact that an administrator needs to configure strategies of the network devices in the to-be-configured link one by one, management and maintenance efficiency is improved, and management and maintenance cost is lowered.

Owner:HUAWEI TECH CO LTD

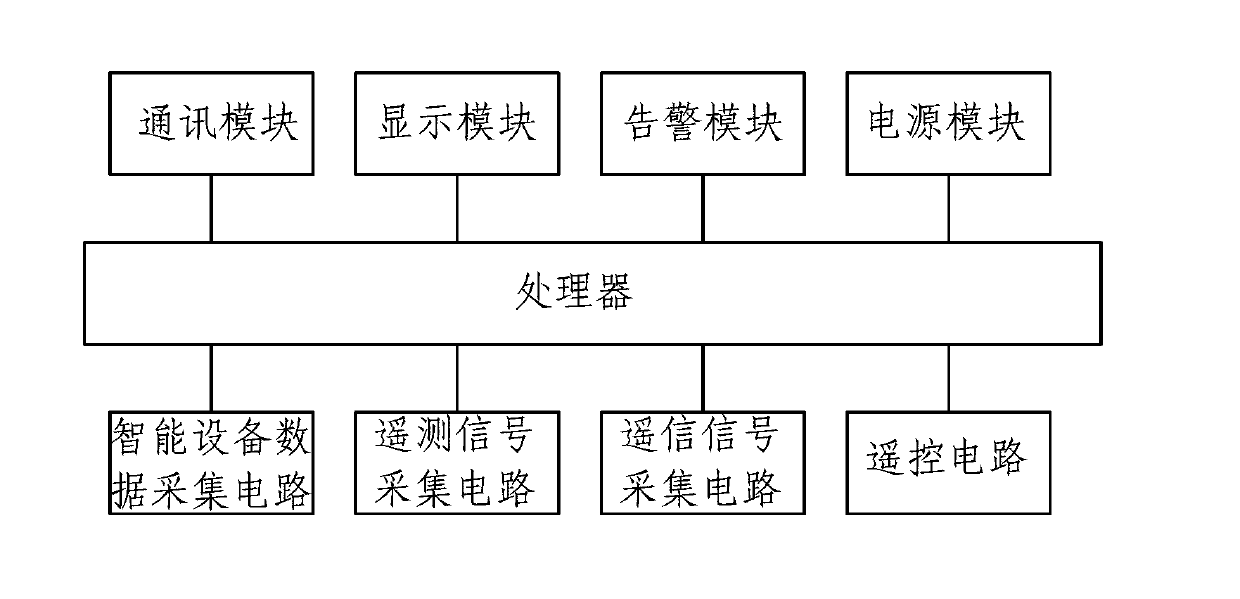

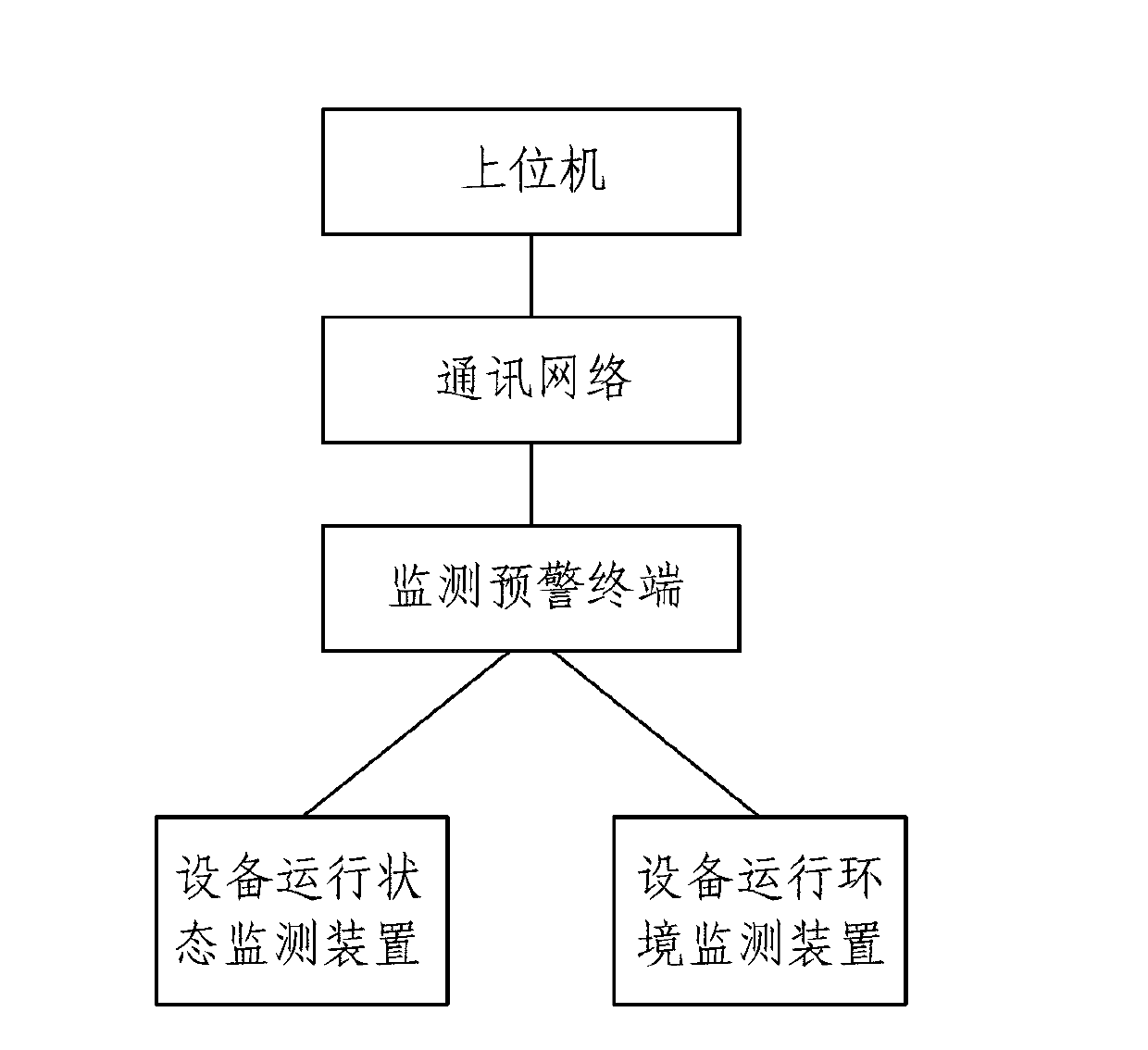

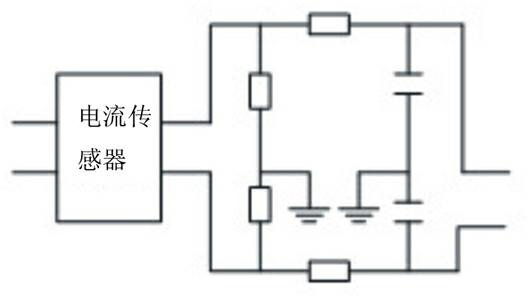

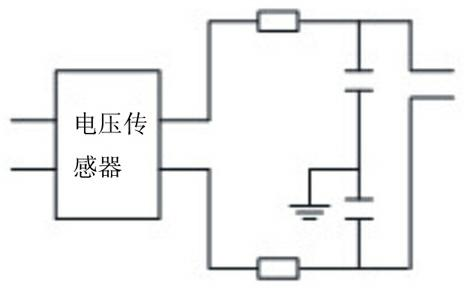

Substation equipment monitoring and early warning terminal

InactiveCN103108034AAddress Security ManagementSolve remote monitoring problemsTransmission systemsCircuit arrangementsTransformerIntelligent equipment

The invention discloses a substation equipment monitoring and early warning terminal which comprises a circuit board, a processor, a communication module, an alarm module, a display module, an intelligent equipment data collecting circuit, a telemetering signal collecting circuit, a remote communication signal collecting circuit, a remote control circuit and a power module, wherein the processor, the communication module, the alarm module, the display module, the intelligent equipment data collecting circuit, the telemetering signal collecting circuit, the remote communication signal collecting circuit, the remote control circuit and the power module are arranged on the circuit board. The processor is connected with a substation equipment operating status monitoring device or an equipment operating environment monitoring device through the intelligent equipment data collecting circuit, the telemetering signal collecting circuit, the remote communication signal collecting circuit and the remote circuit, and carries out data interaction with an upper computer with the communication module accessing to a communication network. The substation equipment monitoring and early warning terminal can carry out on-line monitoring to the operating statuses of various equipment of a transformer substation and factors affecting the safe operating of the transformer substation, enables fault information to be detected in an early stage and processed in time, enables operating personnel to know the operating conditions of the equipment well, and not only guarantees the safe operating of the equipment of the transformer substation, but also reduces the management and maintenance cost of the equipment of the transformer substation.

Owner:国核信息科技有限公司

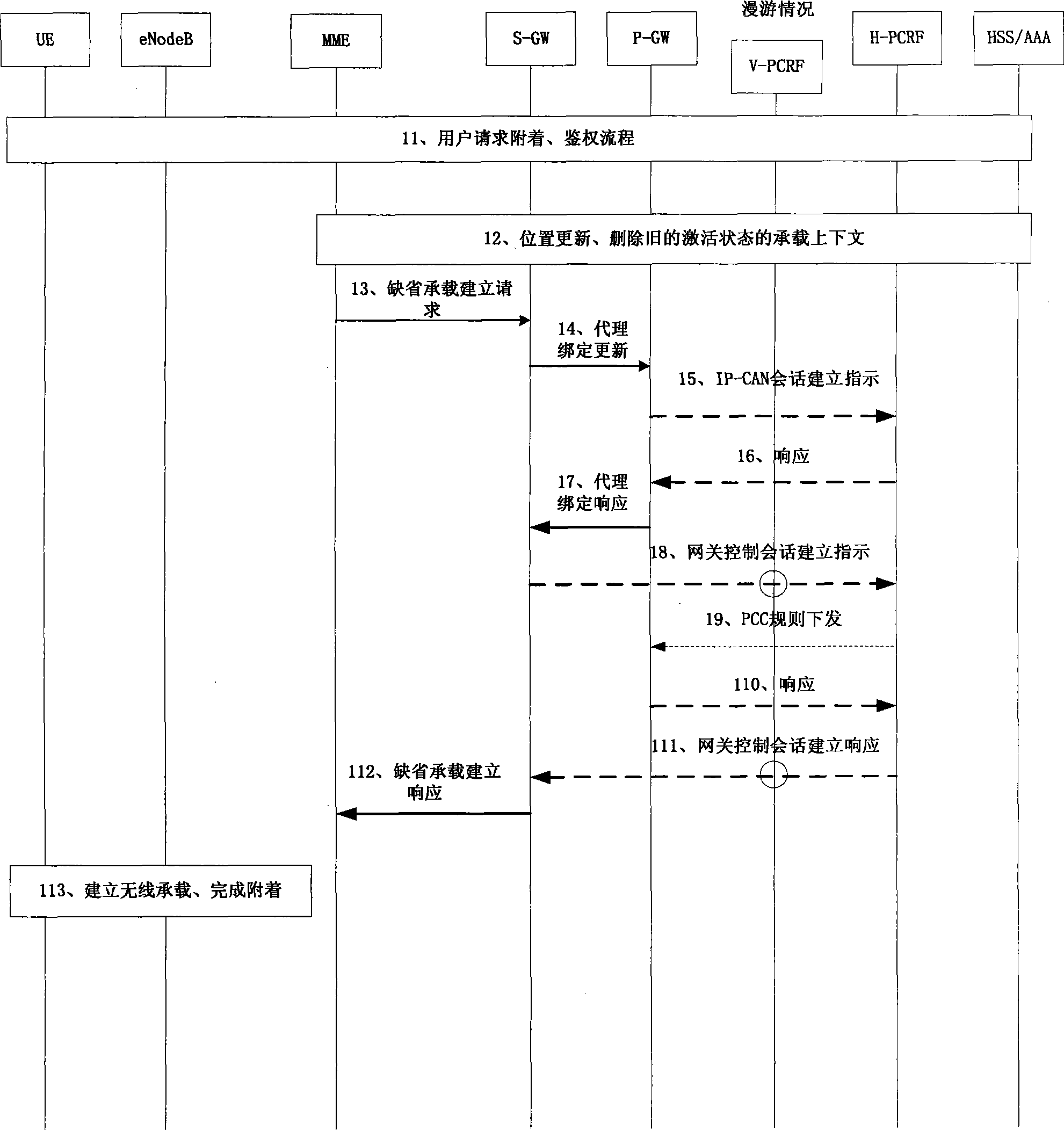

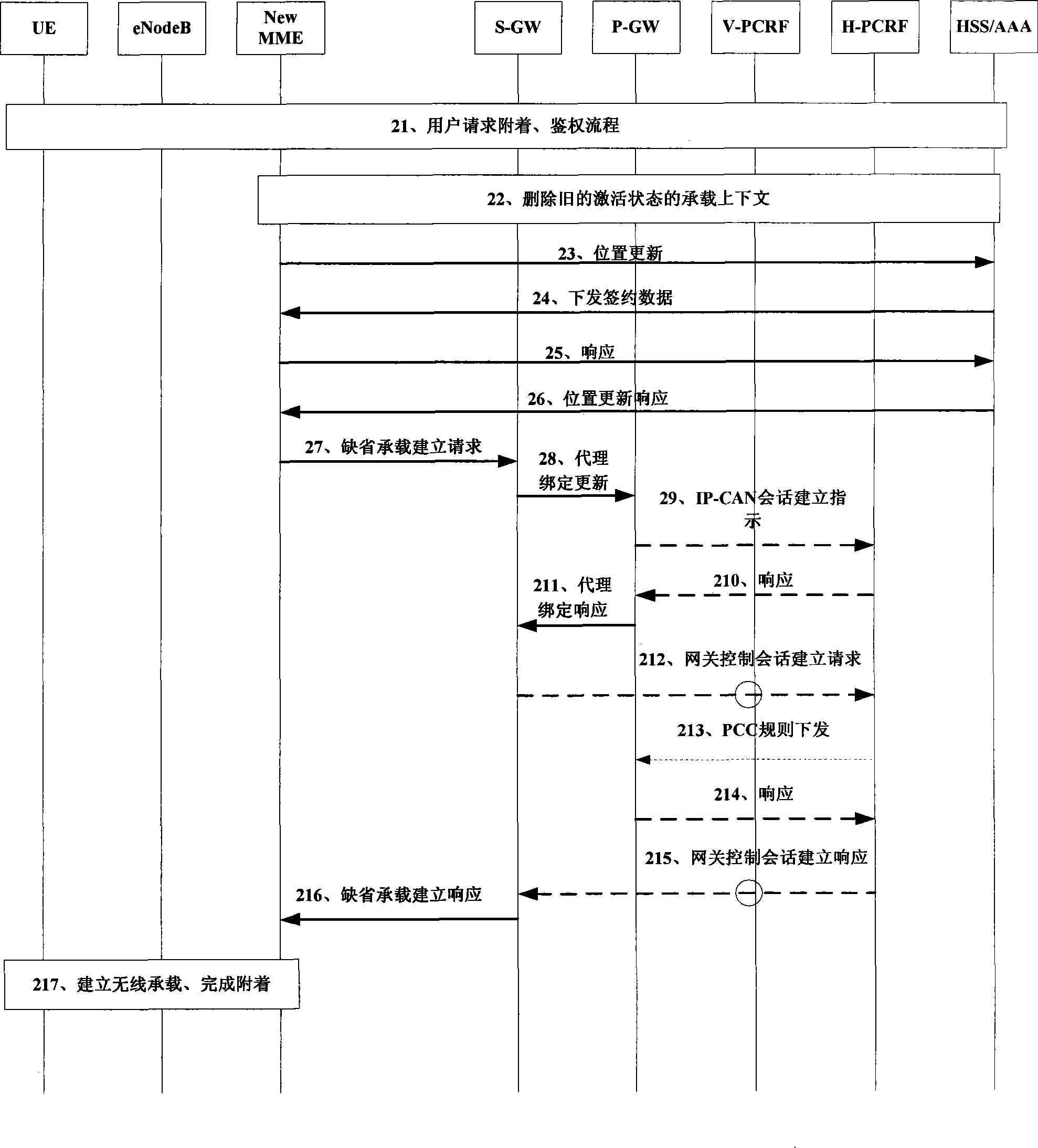

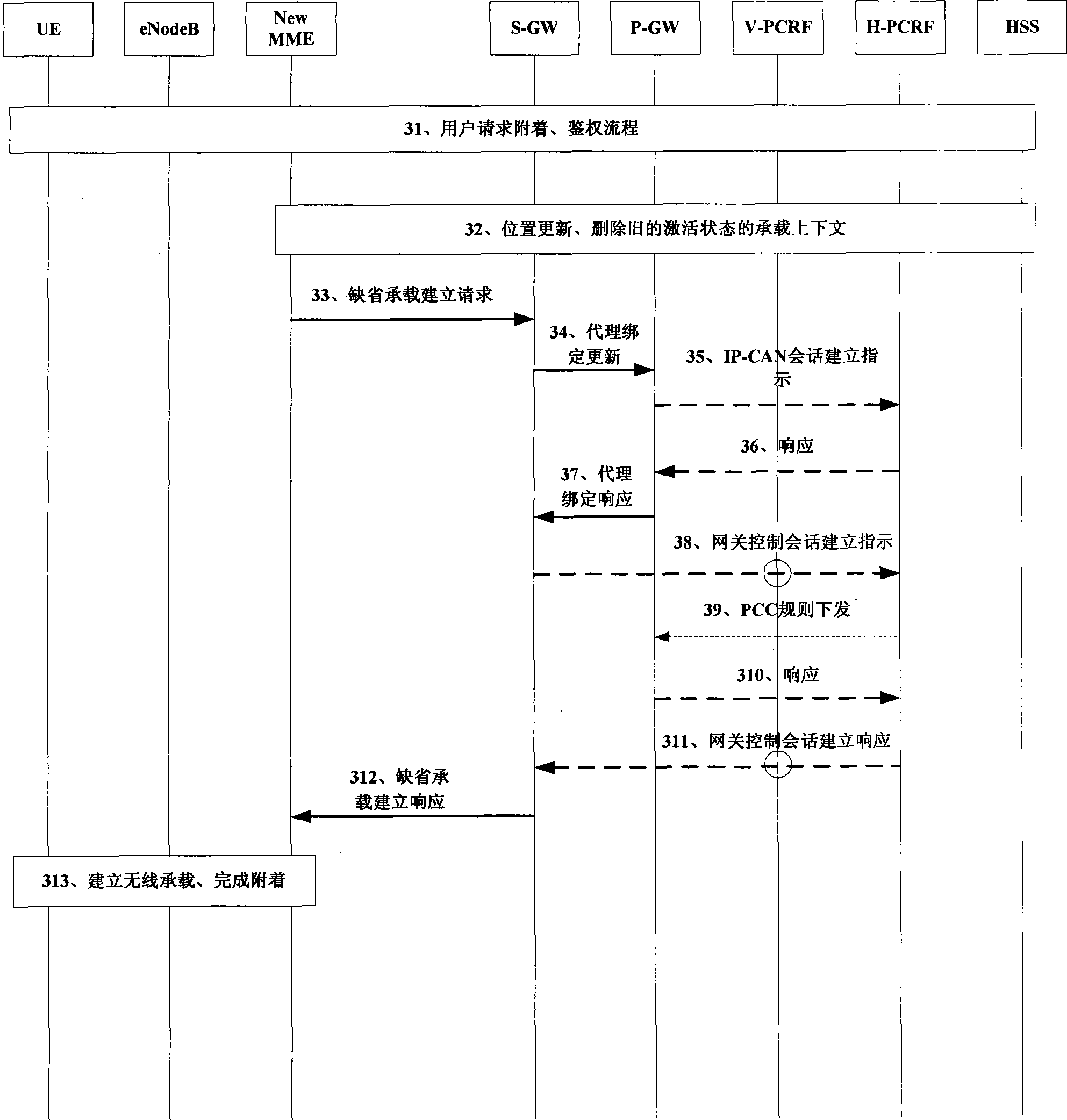

Method and device for triggering policy control and charging function

ActiveCN101472259AReduce management and maintenance costsEasy to expandTelephonic communicationConnection managementAccess networkEmbedded system

The embodiment of the invention provides a method and a device for triggering a PPC (Policy Control and Charging) function, the method mainly comprises the following steps: a PCEF (Policy and Charging Enforcement Function) acquires instruction information triggering the PCC function on the basis of the IP-CAN (IP connected access network) conversation; and the PCEF triggers the PCC function according to the instruction information. By using the invention, the PCEF can judge whether to start the process of the PCC function according to the dynamically obtained instruction information triggering the process of the PCC function on the basis of the IP-CAN conversation, thereby reducing the management and the maintenance costs of an operator and helping expand the subscriber service.

Owner:HUAWEI TECH CO LTD

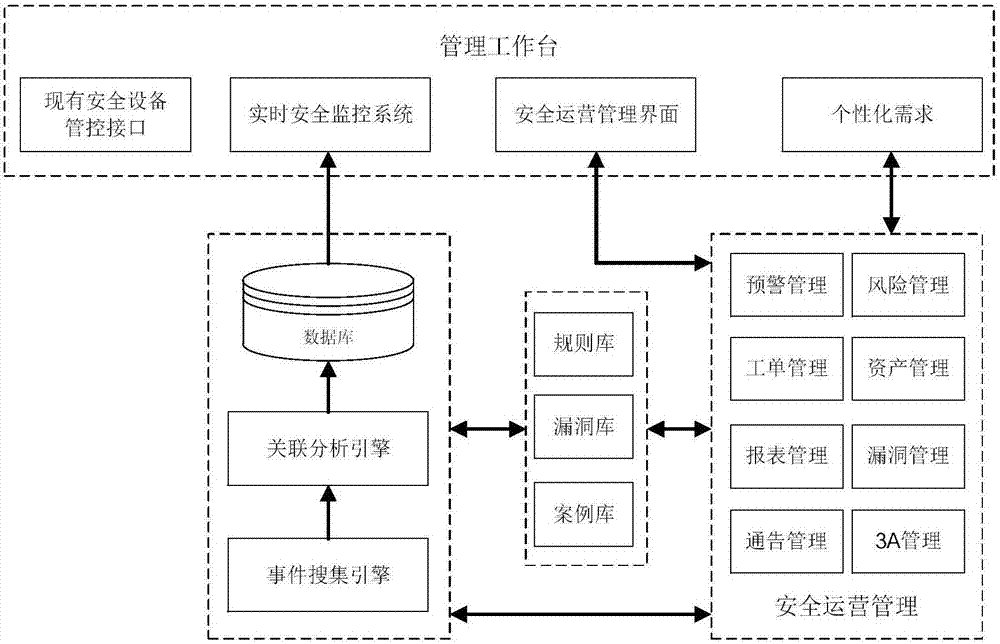

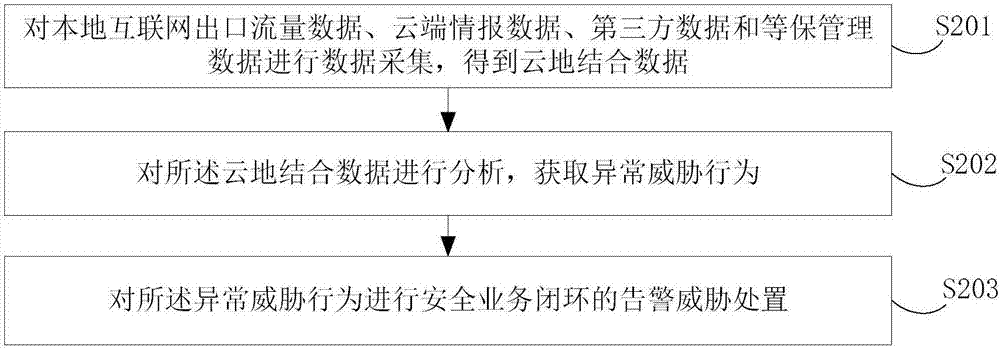

Cloud and local combined data processing method and device

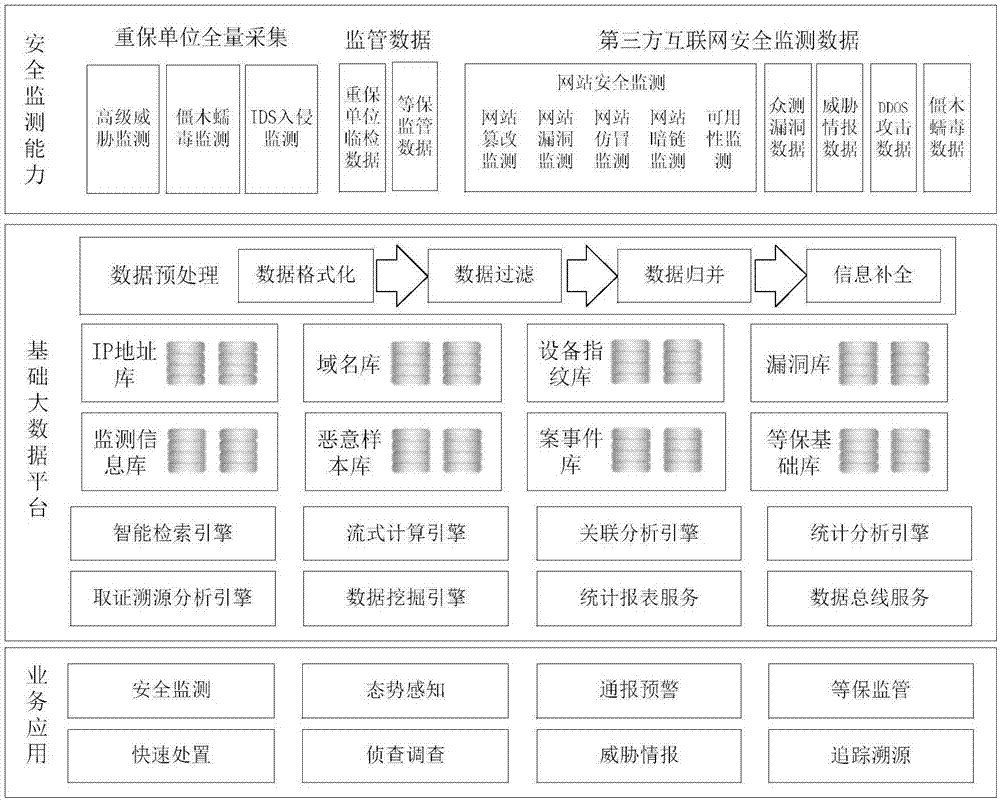

InactiveCN107547526AComprehensive collectionGuaranteed DiscoveryTransmissionTraffic capacityThird party

The embodiment of the invention discloses a cloud and local combined data processing method and device. The method comprises the steps of: performing data acquisition of local internet export flow data, cloud intelligence data, third-party data and grade protection management data, so that cloud and local combined data is obtained; analyzing the cloud and local combined data to obtain an abnormalthreat behaviour; and, performing security service closed-loop warning threat disposal of the abnormal threat behaviour. The device is used for executing the method. In the embodiment of the invention, the local data, the cloud data, the third-party data and the grade protection management data are acquired; therefore, the data acquisition is relatively comprehensive; the coverage rate is relatively high; discovery, detection and security analysis on an important event can be ensured; simultaneously, the security service closed-loop warning threat disposal is carried out for the abnormal threat behaviour; a whole set of staged flexible scheme, which is continuously expanded, is provided; and the management and maintenance cost of a system is reduced.

Owner:BEIJING QIANXIN TECH

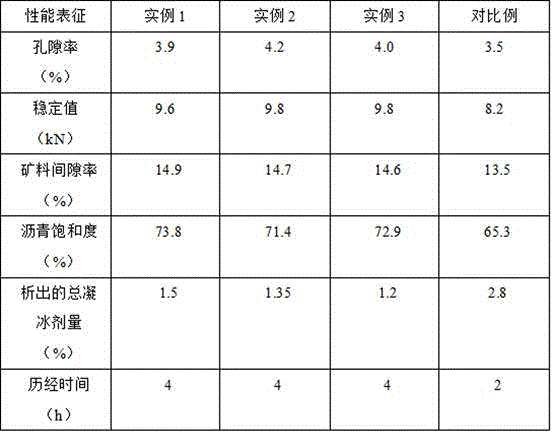

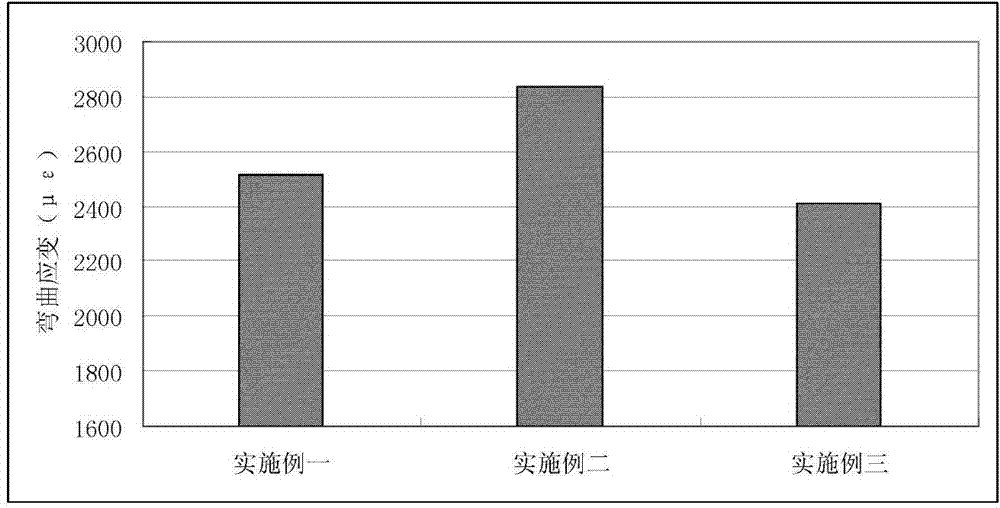

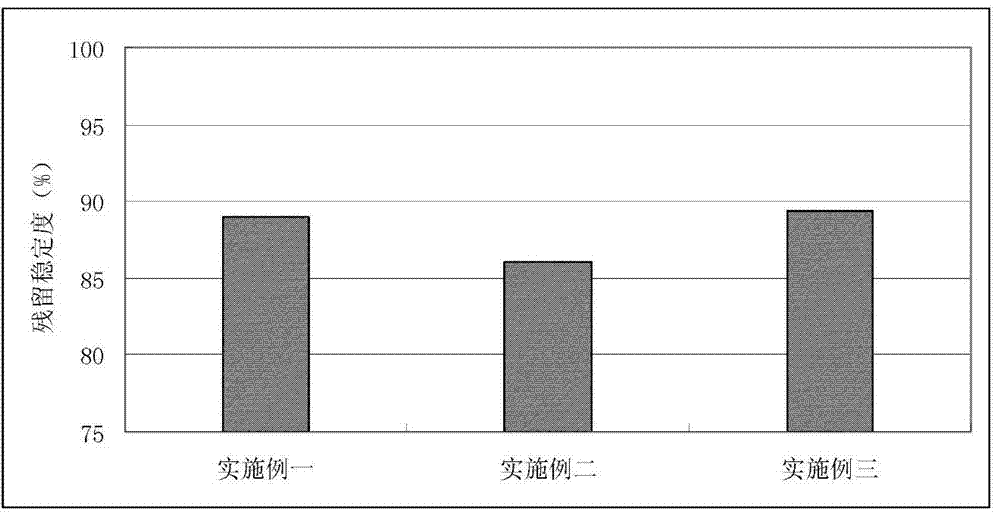

Antifreeze asphalt mixture and preparation method thereof

The invention relates to an antifreeze asphalt mixture and a preparation method thereof and belongs to the technical field of road construction. A calcium acetate melting agent is prepared by the aid of acetylene residues to be loaded on the surface of kieselguhr prior to being subjected to low surface hydrophobic treatment to obtain an antifreezing agent, pavement freezing point can be effectively lowered, icy pavement is prevented, long-term pavement antifreezing effect is achieved, maintenance cost of winter pavement management is lowered, releasing of the calcium acetate melting agent can be effectively alleviated through the kieselguhr, and the antifreezing agent can be evenly released within the range of pavement service life. Basic asphalt aggregate sandstone is prepared as required, rubber particles are tightly embedded between the mixture and the rubber particles as well as the stone material, pavement friction is enhanced, the mixture which is compressed is stable in structure, the rubber particles bear higher pressure, the antifreeze material cannot be destroyed during mixing of the asphalt mixture and paving of the asphalt pavement, and long-term antifreezing performance is achieved.

Owner:谢新昇

Method for constructing close-to-nature vegetations in southern coastal sandy land

InactiveCN104488531AImprove growth performanceEasy maintenancePlant cultivationCultivating equipmentsVegetationScaevola taccada

The invention discloses a method for constructing close-to-nature vegetations in a southern coastal sandy land. The method disclosed by the invention comprises the following steps: firstly, screening six plants, namely lpomoea pes-caprae, scaevola taccada, spinifex, vitex rotundifolia, catharanthus roseus and stachytarpheta jamaicensis, which are suitable for planting in the coastal sandy land, and forming two combinatorial planting; then, digging planting holes, adding family manure as a base fertilizer, adding a water-retaining agent, placing straws on the peripheries of the planting holes to form straw checkboards (which have the function of improving the microenvironment (light shading, wind keepout and the like) for seedling growth, and the straws can be used as a fertilizer after being rotted), soaking bag seedlings with water, adding a compound fertilizer, backfilling sand or foreign soil, and maintaining. After about two months, the six plants are relatively good in growth effect and can form the close-to-nature vegetations; in addition, the vegetations are relatively simple to manage and maintain, and the survival rate reaches over 90 percent respectively.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI +1

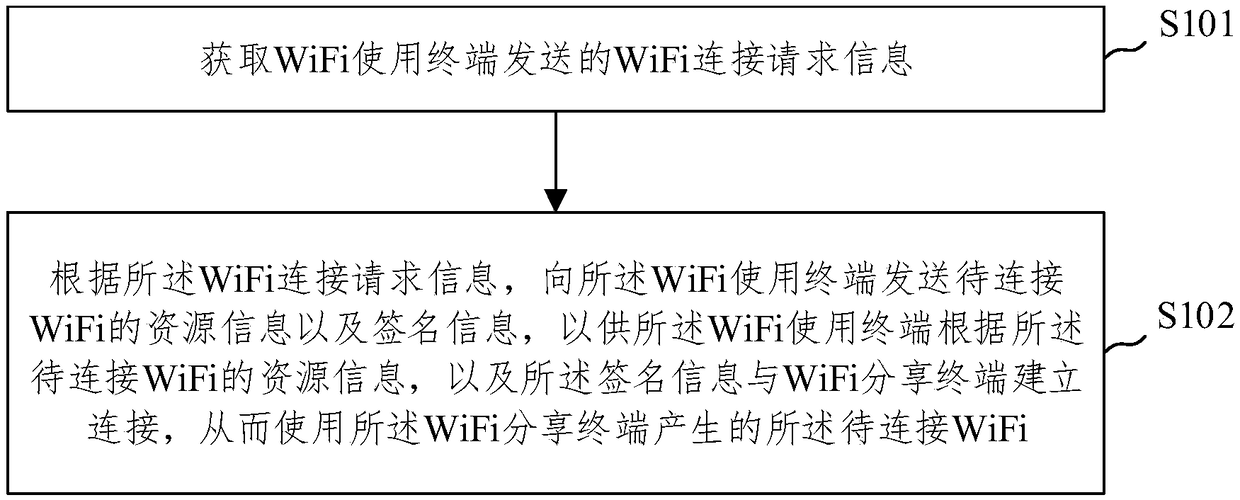

WiFi sharing method and server based on block chain

ActiveCN109168139AImprove securityIncrease usageAccounting/billing servicesTelephonic communicationResource informationUser privacy

The invention provides a WiFi sharing method and a server based on a block chain. The method comprises the following steps: acquiring WiFi connection request information sent by a WiFi using terminal;obtaining WiFi connection request information sent by a WiFi using terminal; obtaining WiFi connection request information from the WiFi using terminal. According to the WiFi connection request information, sending resource information and signature information of WiFi to be connected to the WiFi using terminal, so that the WiFi using terminal establishes a connection with the WiFi sharing terminal according to the resource information of the WiFi to be connected and the signature information, thereby using the WiFi to be connected generated by the WiFi sharing terminal. The invention provides a block chain-based WiFi sharing method and a server, By designing a decentralized form of WiFi sharing platform based on block chain, which improves the security of WiFi sharing network, Compatiblewith public WiFi and private WiFi, WiFi providers are authenticated and WiFi users are billed to make WiFi providers profitable, WiFi resources that motivate WiFi sharing and provide convenience to users are realized, user WiFi information is protected and user privacy data is protected.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Automatic backup and recovery system of cloud host

InactiveCN108874590AReduce cost pressureBreak through architectural limitationsRedundant operation error correctionClient-sideCloud storage

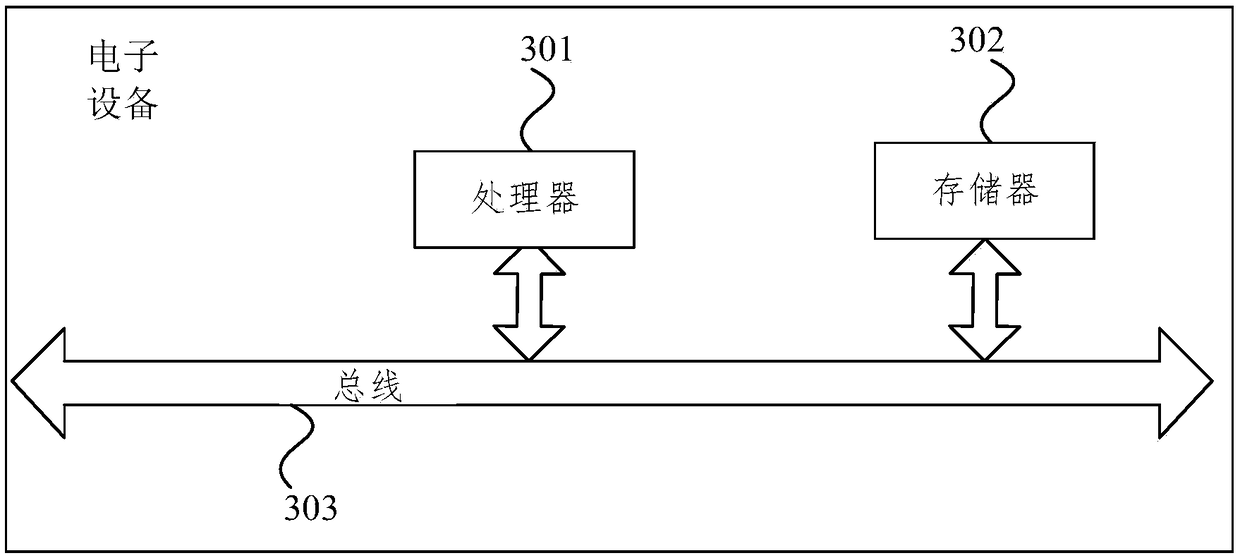

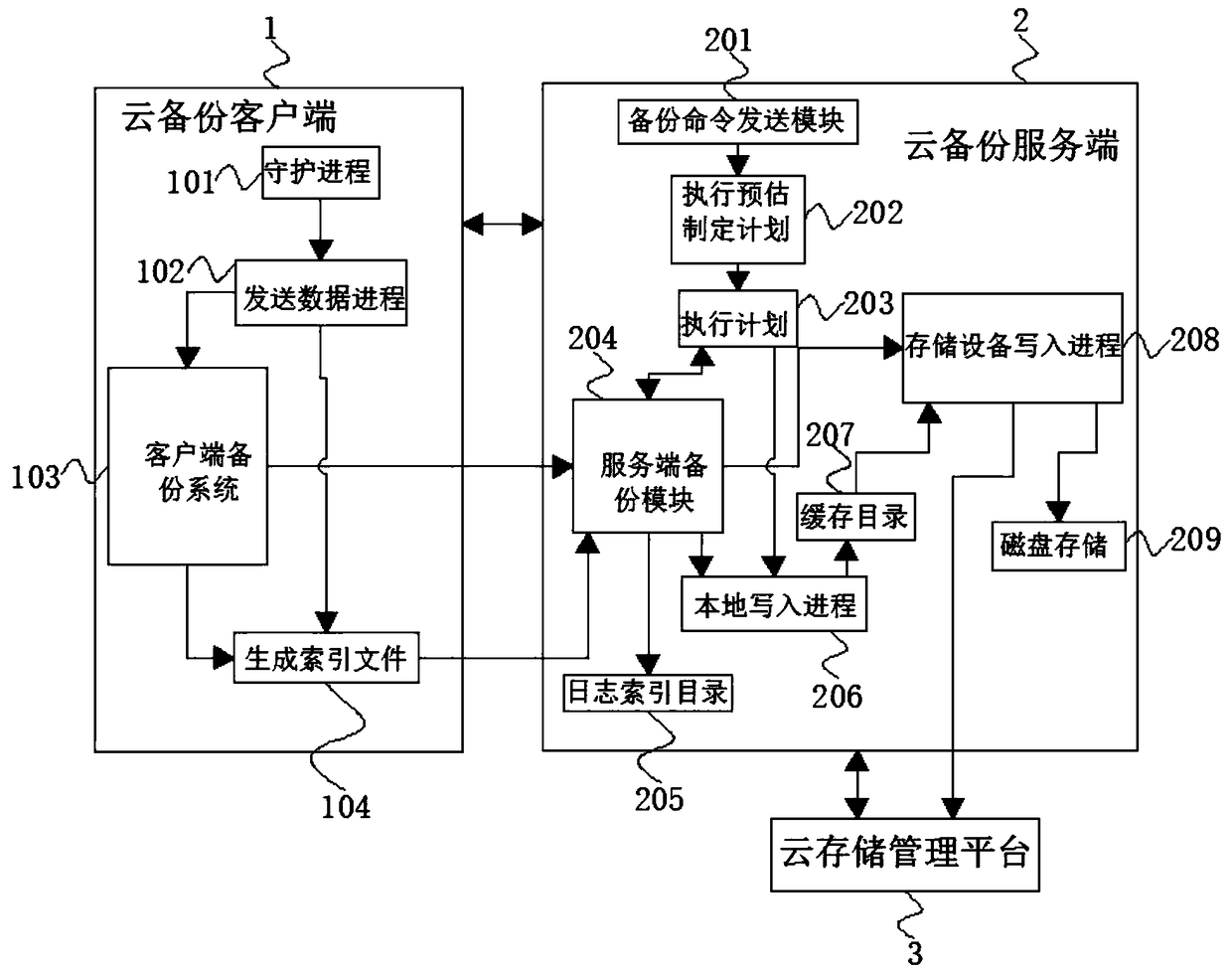

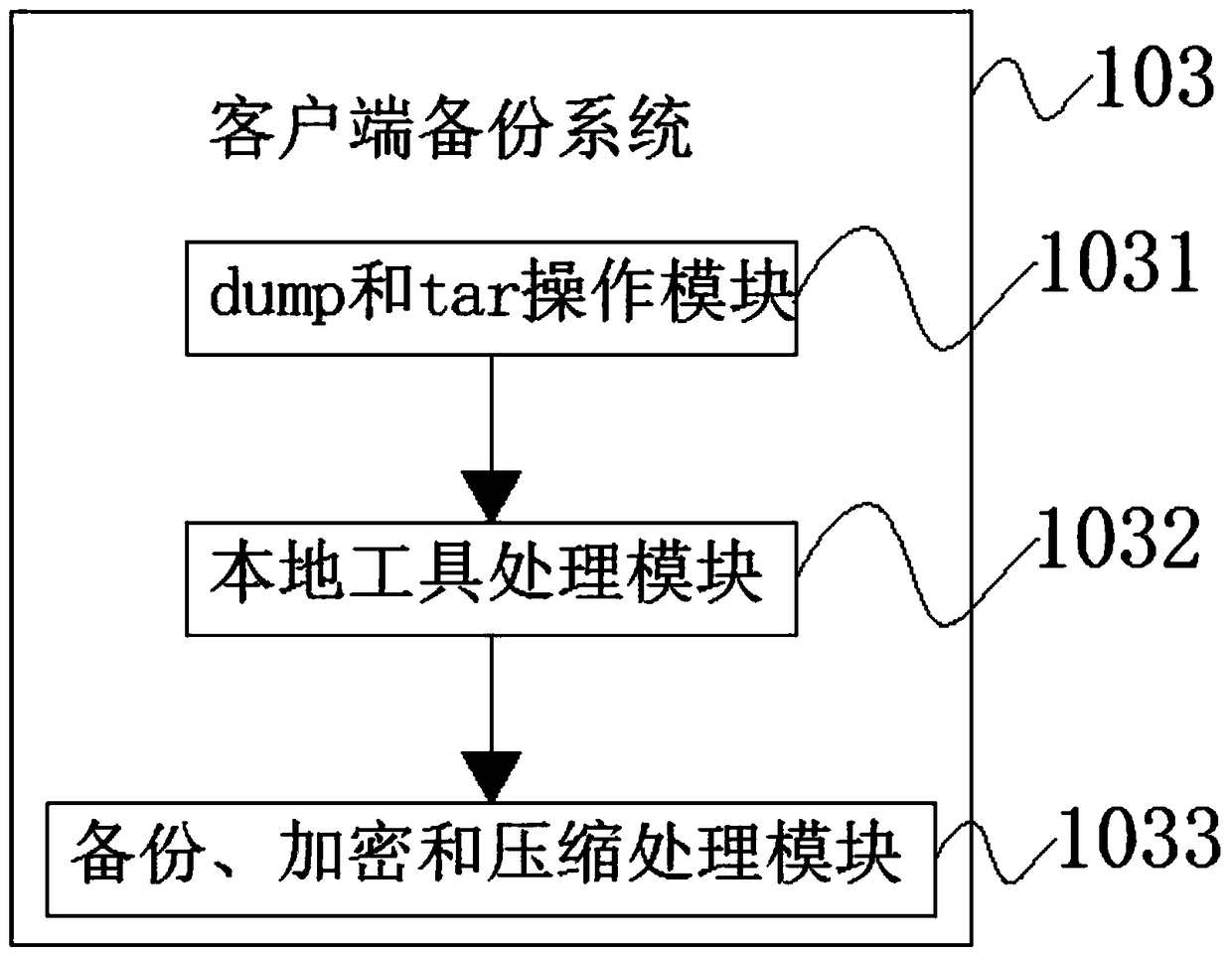

The invention discloses an automatic backup and recovery system of a cloud host. The system comprises a cloud backup client, a cloud backup server and a cloud storage management platform, wherein a bidirectional connection is achieved between the cloud backup client and the cloud backup server, and a bidirectional connection is achieved between the cloud backup server and the cloud storage management platform; the cloud backup client comprises a daemon process, a data sending process, a client backup system and an index generation file. The system relates to the field of network data backup technologies. The automatic backup and recovery system of the cloud host can relieve the cost pressure of middle and small-sized enterprises on backup service usage, the server fuses proxy server and backup server functions, the limitation of traditional frameworks is broken, the backup structure is simplified, and the cloud storage is used as a storage rear-end, so that the problem that a transmission bottleneck and a single-point fault between the storage system and the computing system is avoided, the management and maintenance costs of the backup system are reduced, and the guarantee is provided for reliability and stability of data storage.

Owner:武汉商启网络信息有限公司

Freezing-proof bituminous mixture as well as preparation method and construction method thereof

InactiveCN103771765AWith rubbingWith denseIn situ pavingsSnow removalEnvironmental resource management

The invention relates to a freezing-proof bituminous mixture as well as a preparation method and a construction method thereof, and belongs to the field of engineering technology. According to the invention, Mafilon is added into a bituminous mixture, so that the problem that bituminous pavement freezes in winter is solved, and the freezing point of the frozen pavement can be lowered to relieve freezing of the pavement in winter. The preparation process of the freezing-proof bituminous mixture is simple and convenient, so that the service performance of the bituminous mixture is ensured, and the effect of reliving the freezing of the pavement is achieved. According to the invention, the freezing temperature of the pavement can be lowered to about -3 DEG C to -5 DEGC; a pavement of a place with large snowfall is more easily subjected to snow removal as compared with a common pavement, and a great quantity of human, material and financial resources are reduced; the mixture contains components for relieving freezing, so that the effect of preventing accidental freezing is achieved; the driving safety of a car on the pavement can be improved in winter, and traffic accidents are reduced; compared with the common method for removing ice through spilling salt and the like, the ice removing method adopting the bituminous mixture has the advantages that nearly no damage to the environment is caused, a pavement method for protecting ecology is realized, and the pollution to the environment is reduced; the cost for the management and maintenance of the pavement in winter is lowered, and the better economical efficiency is achieved.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

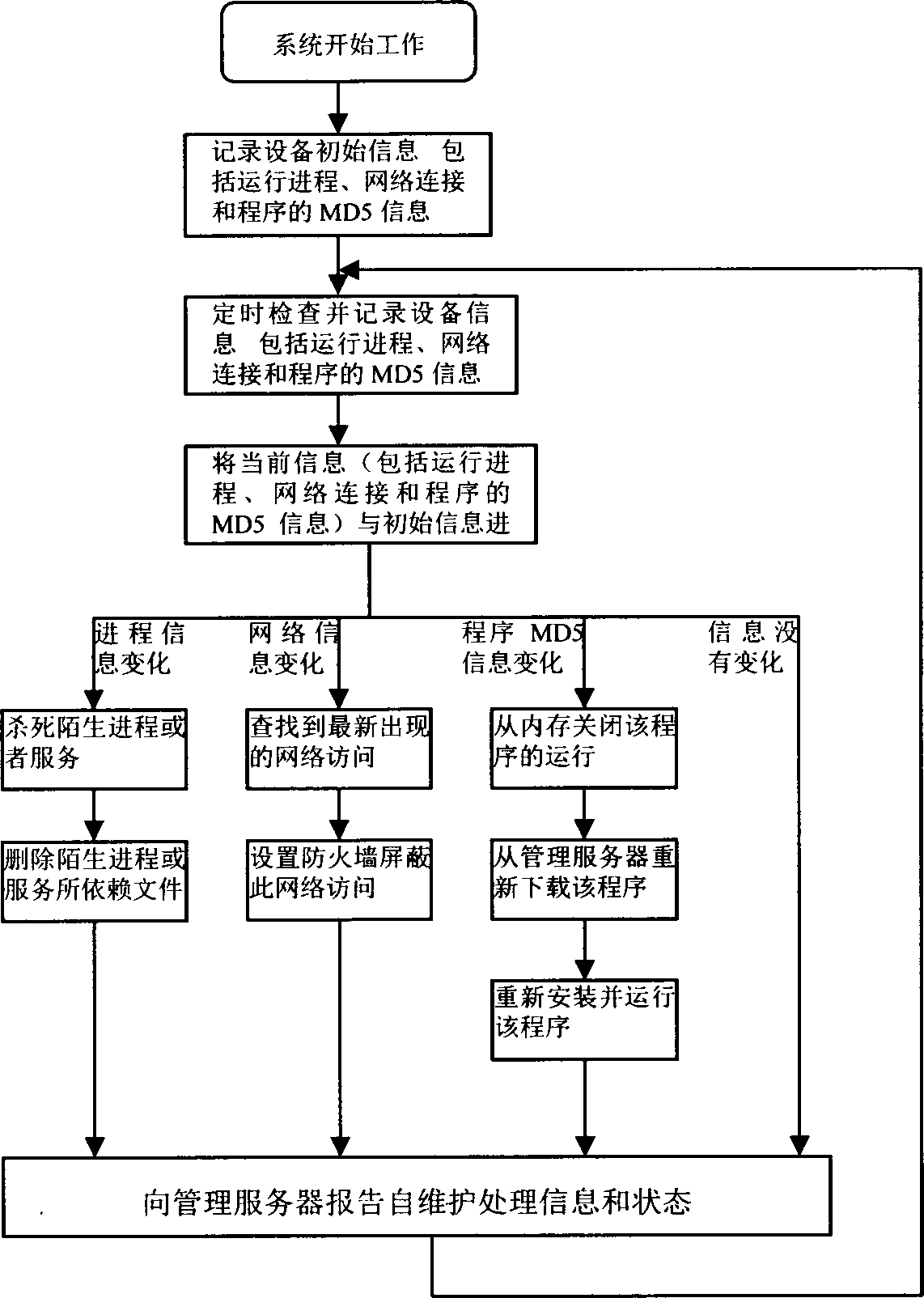

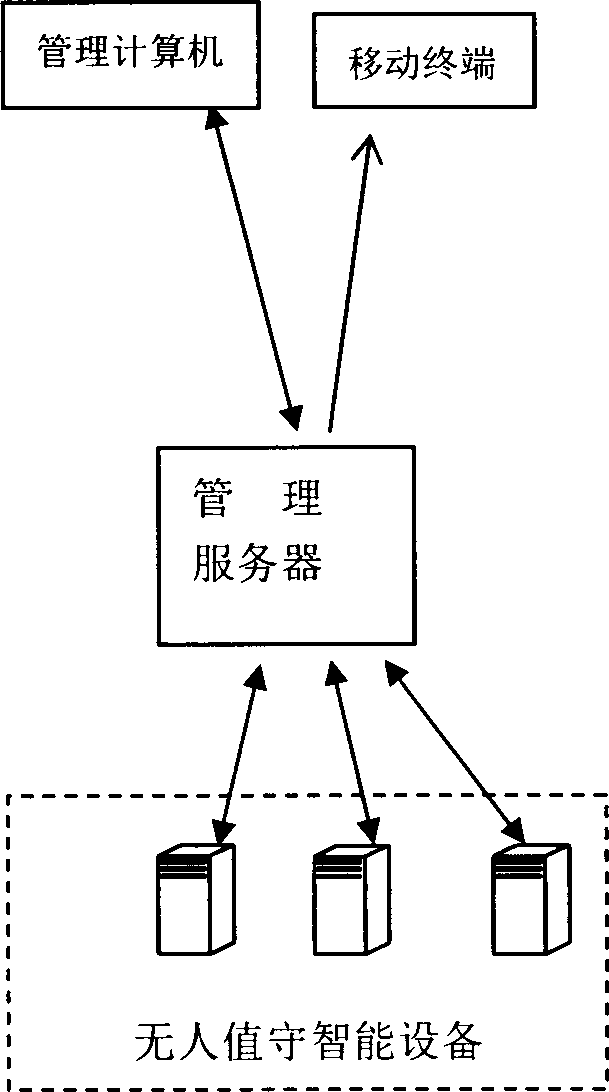

Self-maintenance and management system and method for unattended intelligent device

InactiveCN104168126AReduce overheadGuaranteed to workData switching networksSelf maintenanceNetwork connection

The invention discloses a self-maintenance and management system and method for an unattended intelligent device. The method comprises the following steps: 1) the intelligent device is internally provided with a monitoring program used for detecting running status of the intelligent device at regular time and carrying out self-maintenance according to the setting; 2) when the system begins to work normally, the monitoring program records running process and network connection information in the intelligent device, and carries out MD5 verification on important programs in the intelligent device and records summary information; and 3) the intelligent device checks the change conditions of the running process, the network connection and MD5 information of the programs through the monitoring program at regular time, and makes a comparison with initial running process, network connection and MD5 information of the programs, and then, takes corresponding processing measures. With the self maintenance method, the problem of safety fault management of the unattended intelligent device can be solved automatically in a quick and low-cost manner, and the functions of finding the problems automatically and alarming and automatically maintaining the work environment of the system and the like can be realized.

Owner:江苏华视文化传媒有限公司

Credible power access control method based on block chain

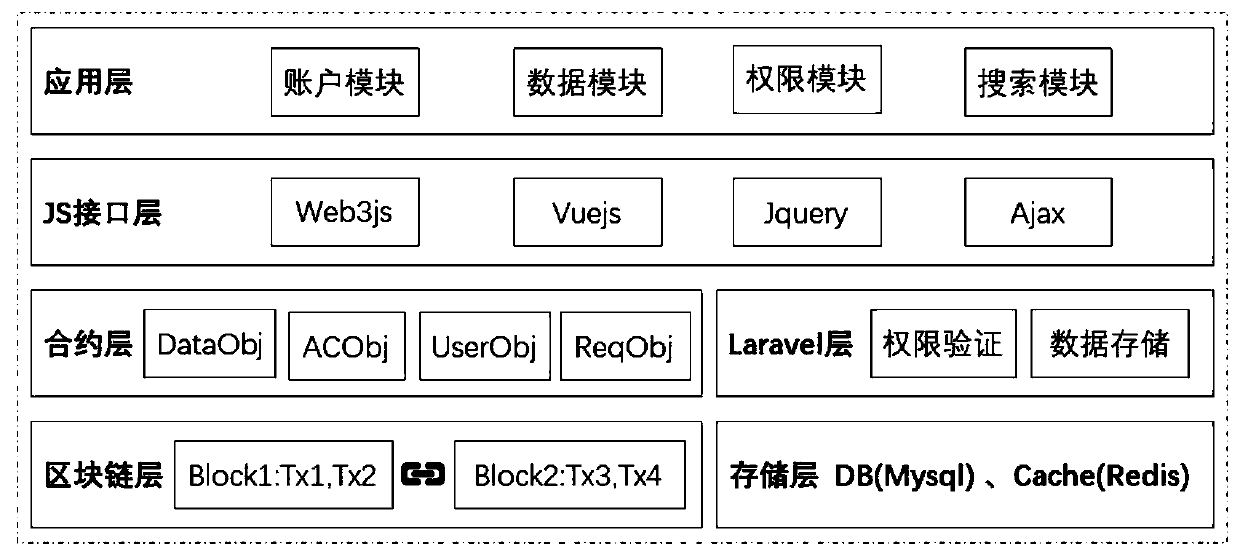

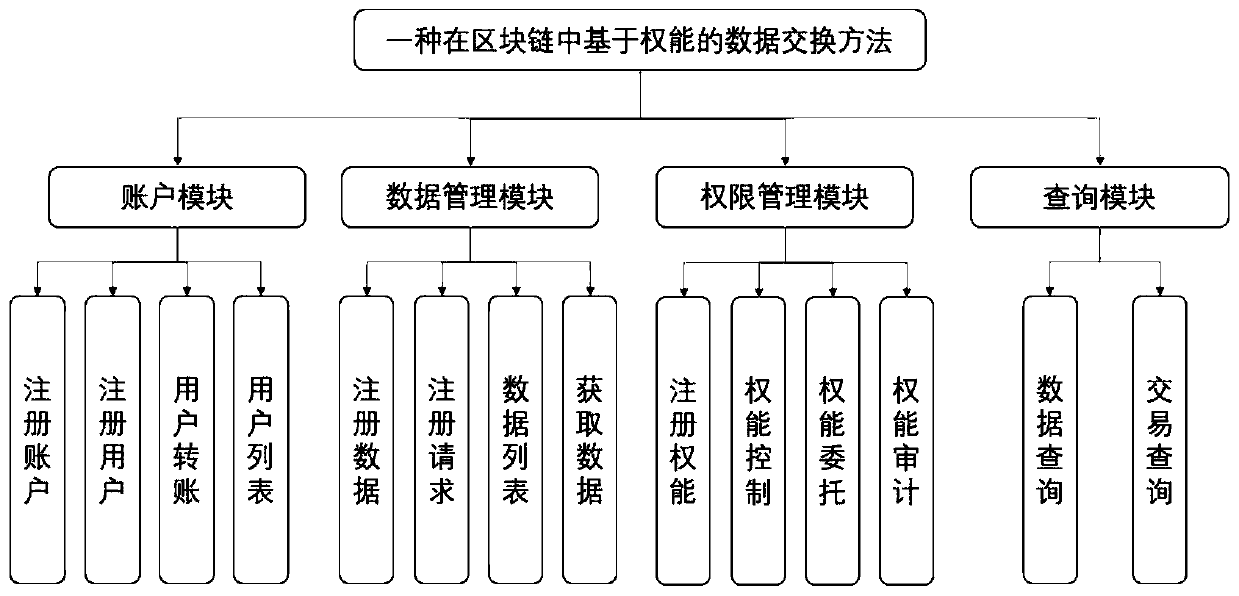

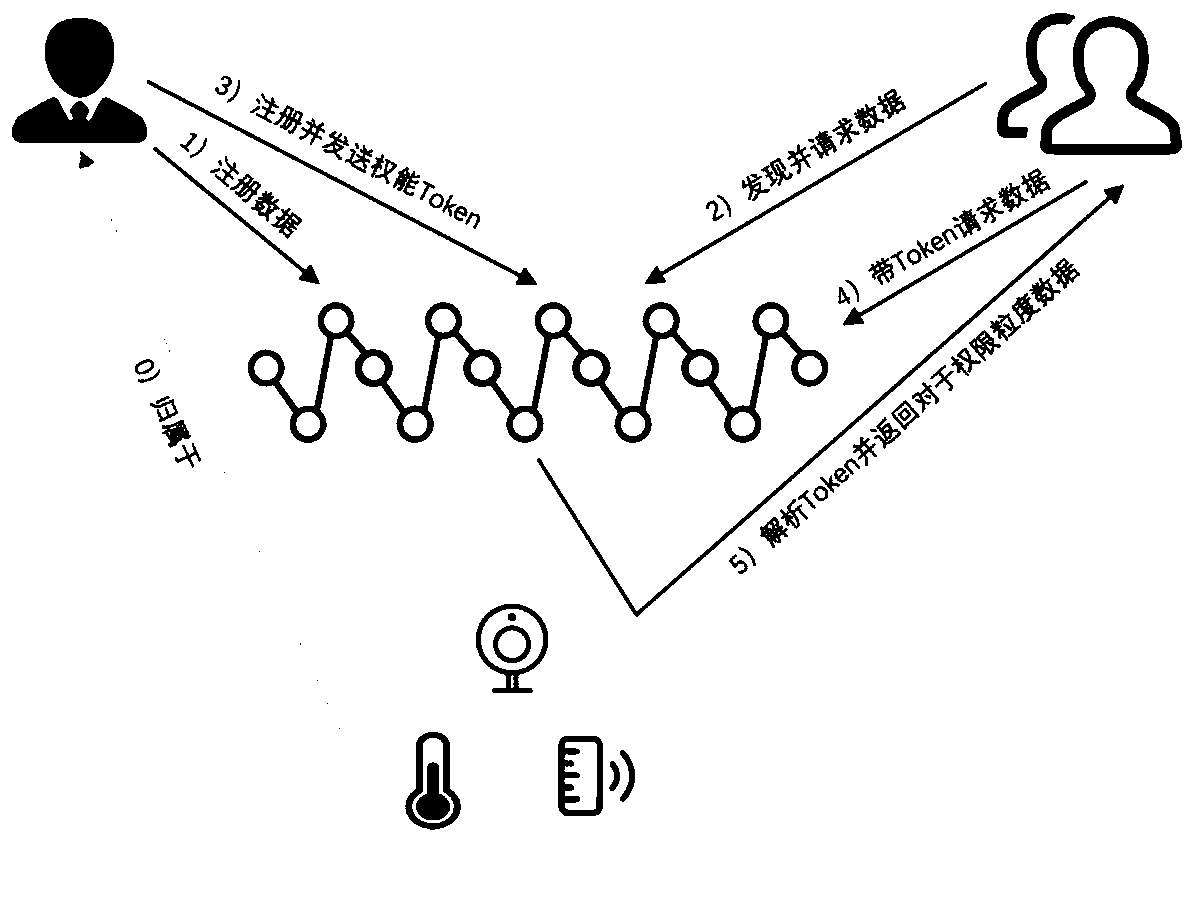

ActiveCN110222518AEnsure safetyReduce management and maintenance costsDigital data protectionTransmissionData exchangeCentralized management

The invention discloses a credible power access control method based on a block chain, the method is realized based on a data system in a distributed environment, and the system consists of a front-end web page and the block chain. Due to the characteristics of the block chain, the storage performance of the platform is weak, and the platform only stores the data access address without providing adata storage function. Wherein the front end consists of a Vue framework and Web3.Js for calling a block link port; the block chain platform uses an Ethereum platform, the Solidity language is used on the Ethereum platform to compile the logic of the intelligent contract, and as the Solidity language realizes the complete intelligent contract programming of the graph, the method is based on the private chain deployed by the Ethereum platform. According to the method, the problem that divergence and conflicts may be generated after data exchange among users is solved through power and energy exchange operation chaining, the problem is rapidly positioned, and objective, real and effective proof is provided; and the management cost and the maintenance cost are greatly reduced, and meanwhile,the risks of attacks, privacy leakage and the like caused by centralized management are also avoided.

Owner:BEIJING UNIV OF TECH

Method for improving top-grafting survival rate of camellia trees

InactiveCN108450226AReduce lossSpeed up recoveryGraftingFertilising methodsCamellia oleiferaRootstock

The invention discloses a method for improving the top-grafting survival rate of camellia trees. The method includes the steps of grafting time selection, rootstock selection, rootstock treatment, scion collection, grafting, first rootstock binding, second rootstock binding and fostering and fertilizing management. On sunny days from May to July every year, robust camellia tree branches on the camellia trees aged 20 to 30 years are selected as rootstocks; on the basis of a conventional bark-pulling cut-grafting method, it is unnecessary to keep vegetative branches and shading branches, film belts are used for binding the rootstocks from bottom to top one ring after another ring without gaps, and then the rootstocks are covered with moisturizing bags and shading objects; when scion buds survive, the moisturizing bags and the shading objects are removed, and then film belts are used for binding the rootstocks; after grafting, management is conducted in combination with a conventional method. By means of the method, rootstock germination can be effectively inhibited, it is prevented that the rootstocks are subjected to bark cracks and death due to sunburn and water loss of the rootstocks, the costs of management and protection after grafting and crown changing of the camellia trees are effectively reduced, and recovery and formation of crowns of the camellia trees after grafting can be quickened.

Owner:GUANGXI FORESTRY RES INST

Centralized intelligent electric meter

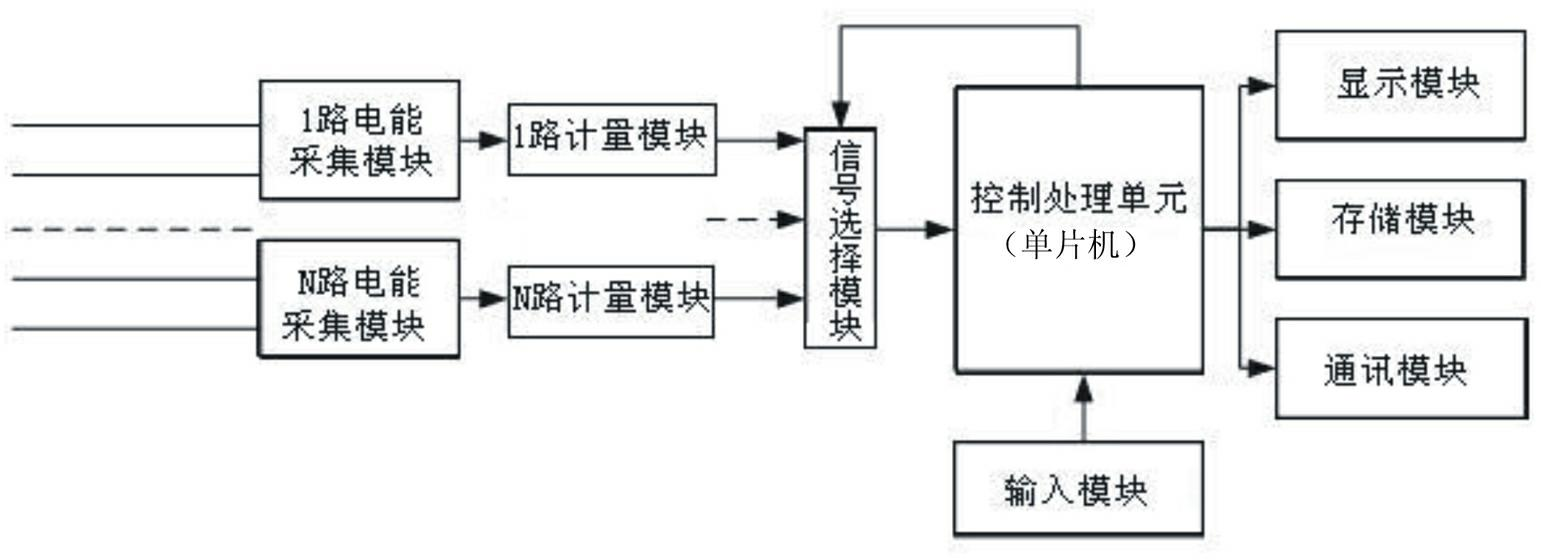

ActiveCN102621380AVisual inspectionRealize individual meteringElectrical measurementsComputer moduleEngineering

The invention relates to a centralized intelligent electric meter. The electric meter comprises a plurality of electric energy sampling modules, wherein each electric energy sampling module is connected with a measuring module; the measuring module is connected with a signal selection module; the signal selection module is connected with a control processing unit; the control processing unit is connected with a display module; each electric energy sampling module acquires the electric quantity of each user and transmits the acquired signal to the measuring module; the measuring module converts the signal acquired by each electric energy sampling module into a frequency signal; the frequency signal passes through the signal selection module and is transmitted to the control processing unit; and the control processing unit processes the signal and transmits the processed signal to the display module for display. The electricity utilization data of a plurality of users is centralized on the same display screen for polling display, so that the requirement of the electric meter on an installation position is reduced, the meter reading efficiency of meter reading personnel is improved, and management and maintenance cost is reduced.

Owner:WUHAN YANGTZE OPTICAL TECH

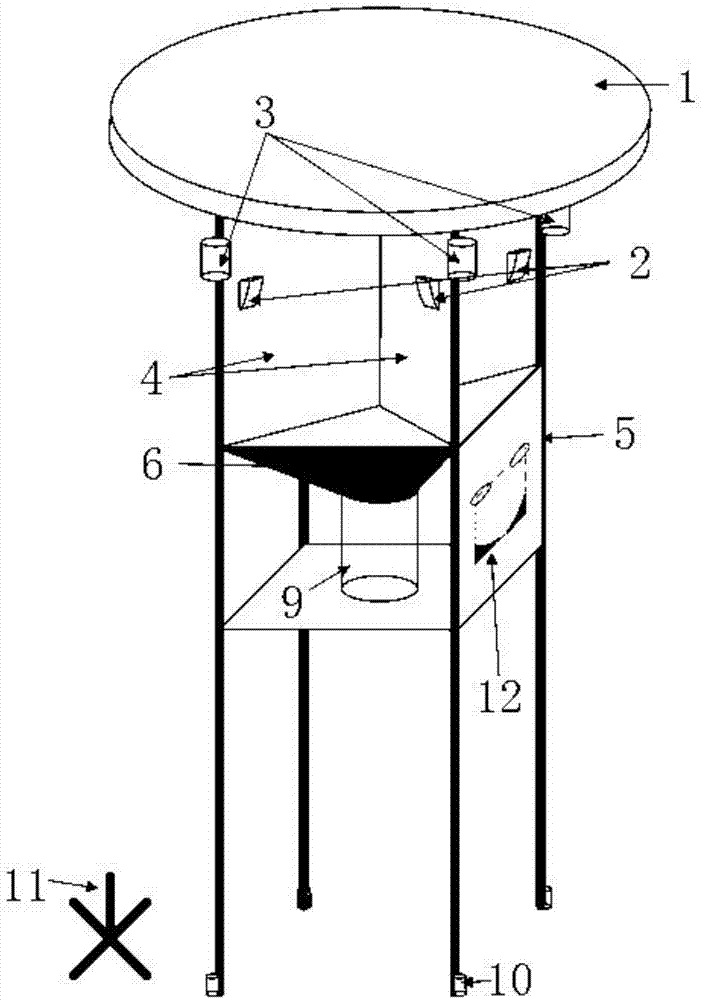

Garden pest monitoring method and large vertical garden pest monitoring device

The invention discloses a garden pest monitoring method and a large vertical garden pest monitoring device. A transparent intercepting plate with a hole is elevated through a bracket, and pests are attracted by means of a slow-release attractant, so that the insects fall into an insect collecting funnel at the bottom after colliding with the transparent intercepting plate; a pest collecting cup containing a specimen preservation solution is arranged below the insect collecting funnel to collect the fallen pests, so that garden pest monitoring can be achieved by counting the pests in the pest collecting cup; meanwhile, the garden pests are subjected to centralized trapping and killing, and the number of the garden pests can be effectively controlled.

Owner:SOUTHWEST FORESTRY UNIVERSITY +2

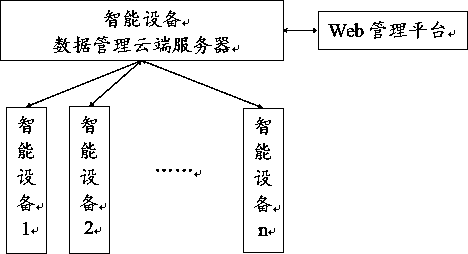

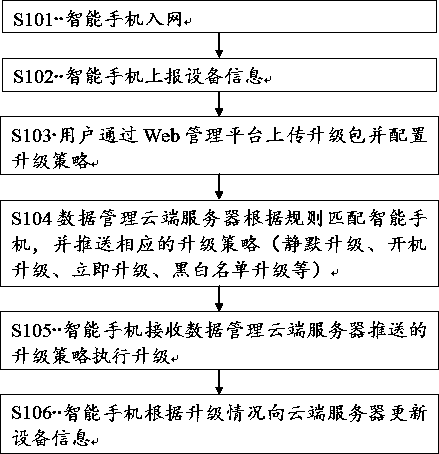

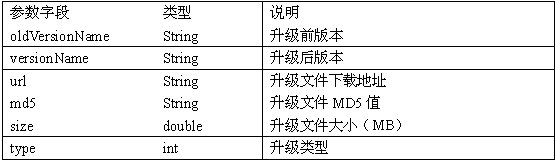

Intelligent equipment upgrading management system and method

InactiveCN110532009ADiversified upgrade operationsReduce management and maintenance costsVersion controlSoftware deploymentData managementBluetooth

The invention belongs to the field of intelligent Bluetooth equipment and using methods, and particularly relates to an intelligent equipment upgrading management system and a method. The system comprises an intelligent equipment, a Web management platform and a data management cloud server. The intelligent equipment logs in and accesses the data management cloud server through a wireless network,and reports equipment information; the Web management platform uploads an upgrade package to the data management cloud server through a wireless network and configures an upgrade strategy; the data management cloud server matches the connected corresponding intelligent equipment according to the upgrading strategy and pushes the upgrading strategy; and the intelligent equipment receives the upgrading strategy pushed by the data management cloud server to execute upgrading. The method has the beneficial effect of solving the problems of disordered upgrade package version management, single upgrade mode and the like in the prior art.

Owner:厦门市思芯微科技有限公司

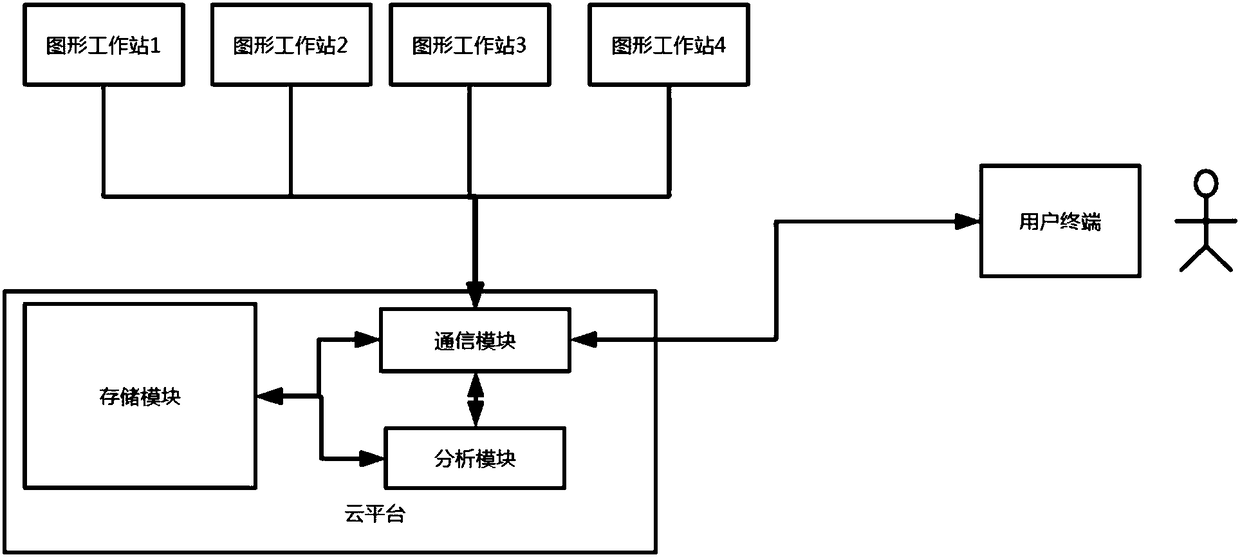

Cloud computation-based GPU performance monitoring system

ActiveCN108733531AReduce management and maintenance costsEffectively monitor usageHardware monitoringPerformance indexWorkstation

The invention relates to a cloud computation-based GPU performance monitoring system. A GPU performance data acquisition unit is used for uploading acquired GPU performance data to a cloud platform-based service center; the service center is responsible for storing the performance data and calculating performance indexes according to rules; and managers can check the real-time performance indexesthrough a mobile terminal or a PC. When the performance indexes exceed a preset range, the service center initiatively notifies the managers through an intelligent terminal. The system is capable of observing GPU performance in real time so as to enable the managers to conveniently grasp the using conditions of GPU resources, and receiving notification information in time, deploying resources andgiving reasonable correspondences when GPU using is overloaded so as to greatly reduce the whole workstation management and maintenance cost and improve the working efficiency of maintenance of the managers.

Owner:南京维拓科技股份有限公司

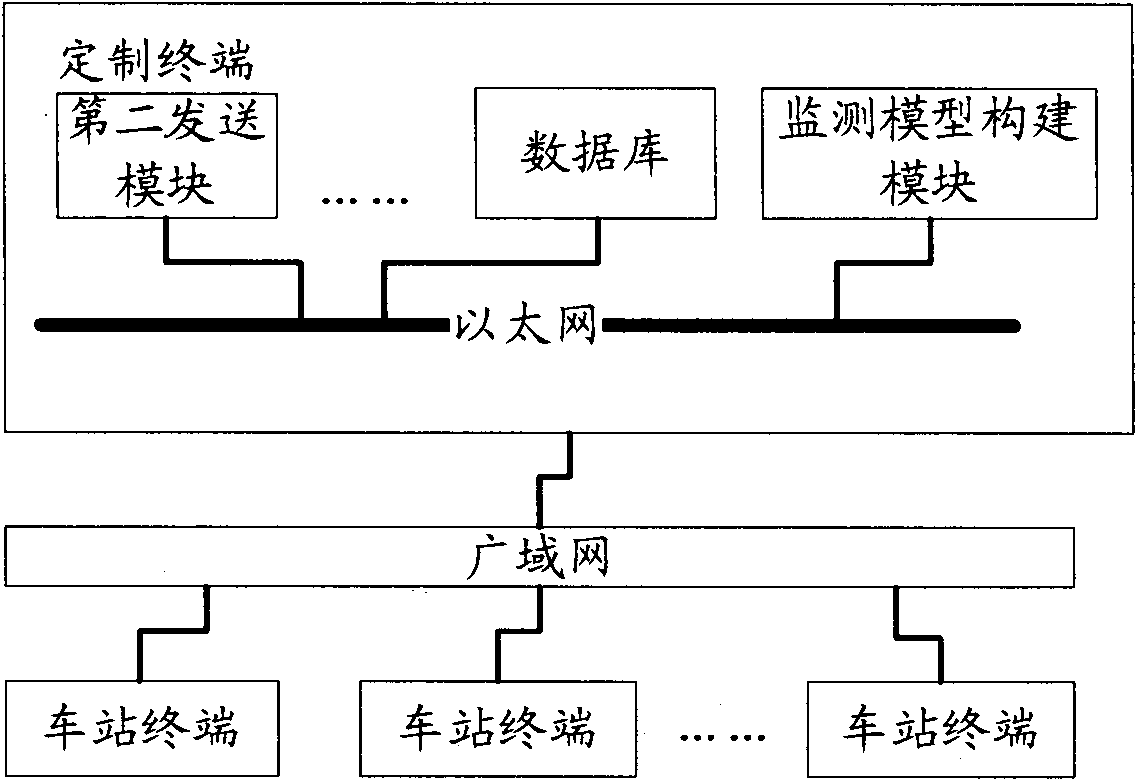

Method, equipment and system for monitoring railway equipment

ActiveCN101905704AReduce workloadReduce management and maintenance costsAutomatic systemsWorkloadSoftware

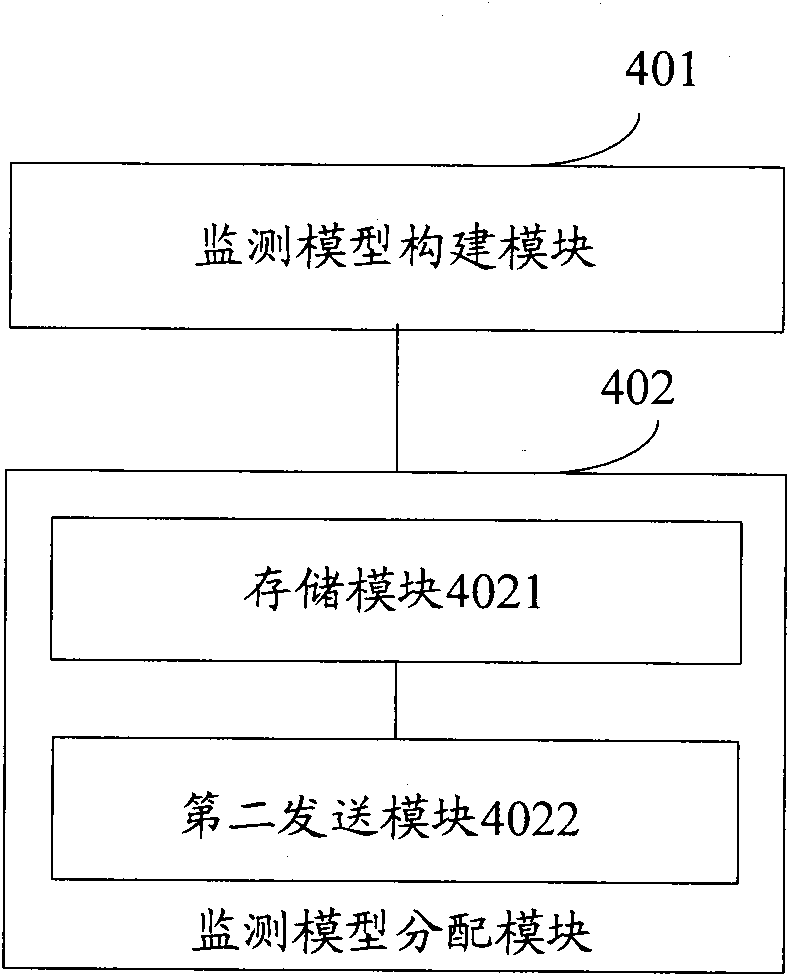

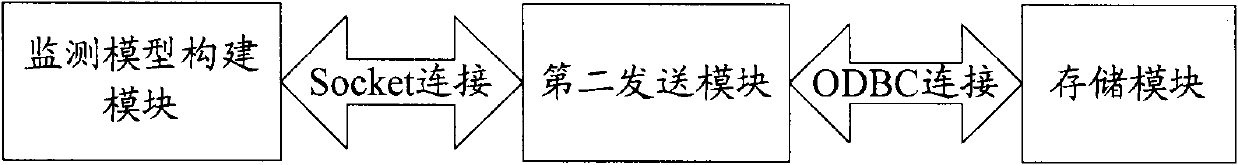

The embodiment of the invention discloses a method, equipment and a system for monitoring railway equipment, wherein the method comprises the following steps of: establishing a monitoring business model according to elements appointed by users in a basis element library, wherein the appointed elements comprise equipment elements for indicating monitored equipment, equipment signal elements for indicating monitored signals, event elements of logic calculation relation for indicating among monitored signals and expression form elements for indicating the expression forms of monitoring results; and distributing the established monitoring business model to every station terminal so that the station terminals analyze the obtained monitoring business model into monitoring control commands and then monitor railway equipment according to the monitoring control commands. The embodiment of the invention can reduce the workload of developers, and reduce the management and maintenance cost for monitoring software by maintenance personnel.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

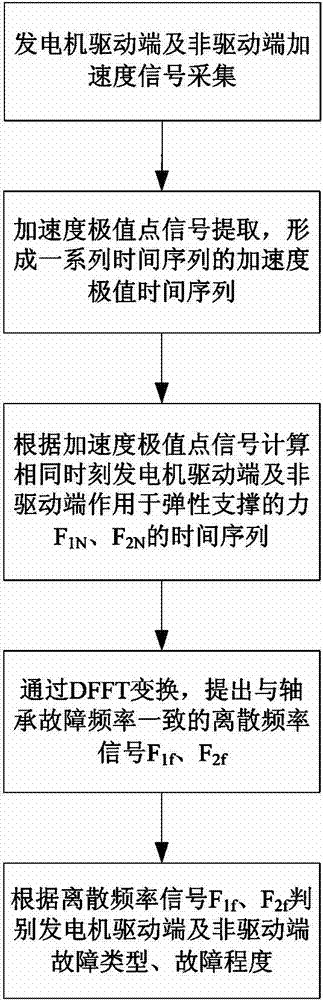

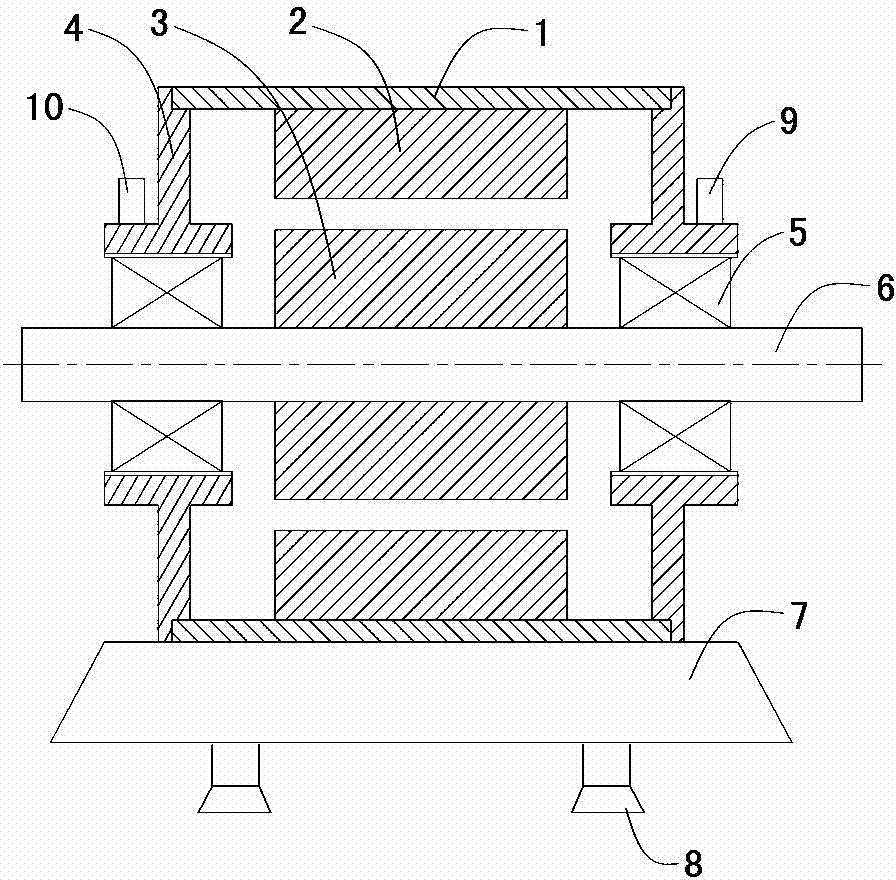

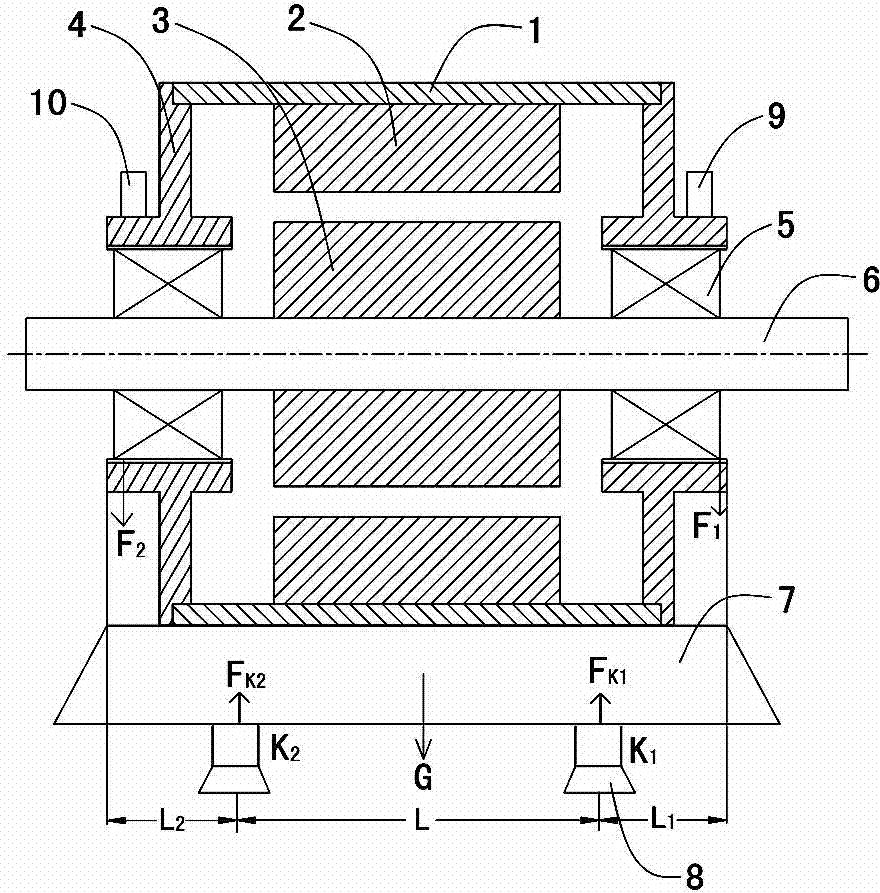

Method and device for judging fault of wind electricity doubly-fed generator rolling bearing

InactiveCN103575535AGuaranteed uptimeWill not misjudgeMachine bearings testingElectricityEngineering

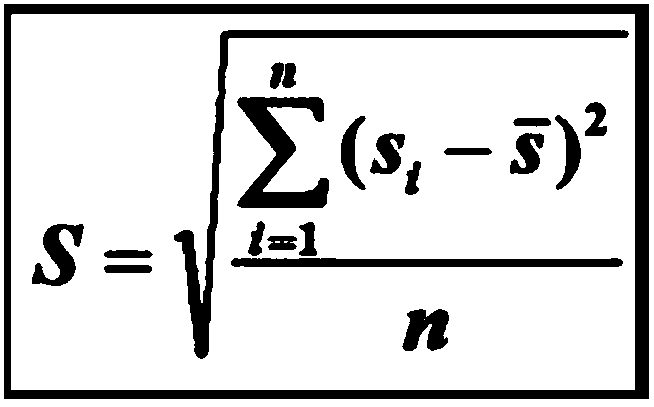

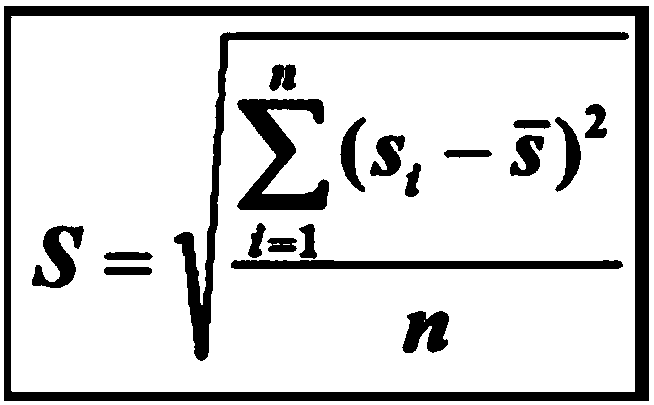

The invention discloses a method and device for judging faults of a wind electricity doubly-fed generator rolling bearing. The method comprises the following steps: respectively detecting acceleration signals of a doubly-fed generator driving end and a non-driving end, respectively extracting acceleration extreme point signals so as to obtain a time sequence of acceleration extreme points, respectively calculating elastic support force to obtain a time sequence of the elastic support force, respectively performing DFFT (Discrete Fast Fourier Transform) so as to obtain bearing fault characteristic frequency signal, respectively performing fault judgment on the a doubly-fed generator driving end and the non-driving end according to the bearing fault characteristic frequency signal, and outputting the judgment result. The device comprises a first acceleration sensor, a second acceleration sensor, an acceleration extreme value point extracting module, an elastic support force calculation module, a fault characteristic frequency calculation module and a fault judgment module. The method and the device have the advantages of precise fault detection, high accuracy, convenience and rapidness in detection, convenience in use, and low bearing management and maintenance cost.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

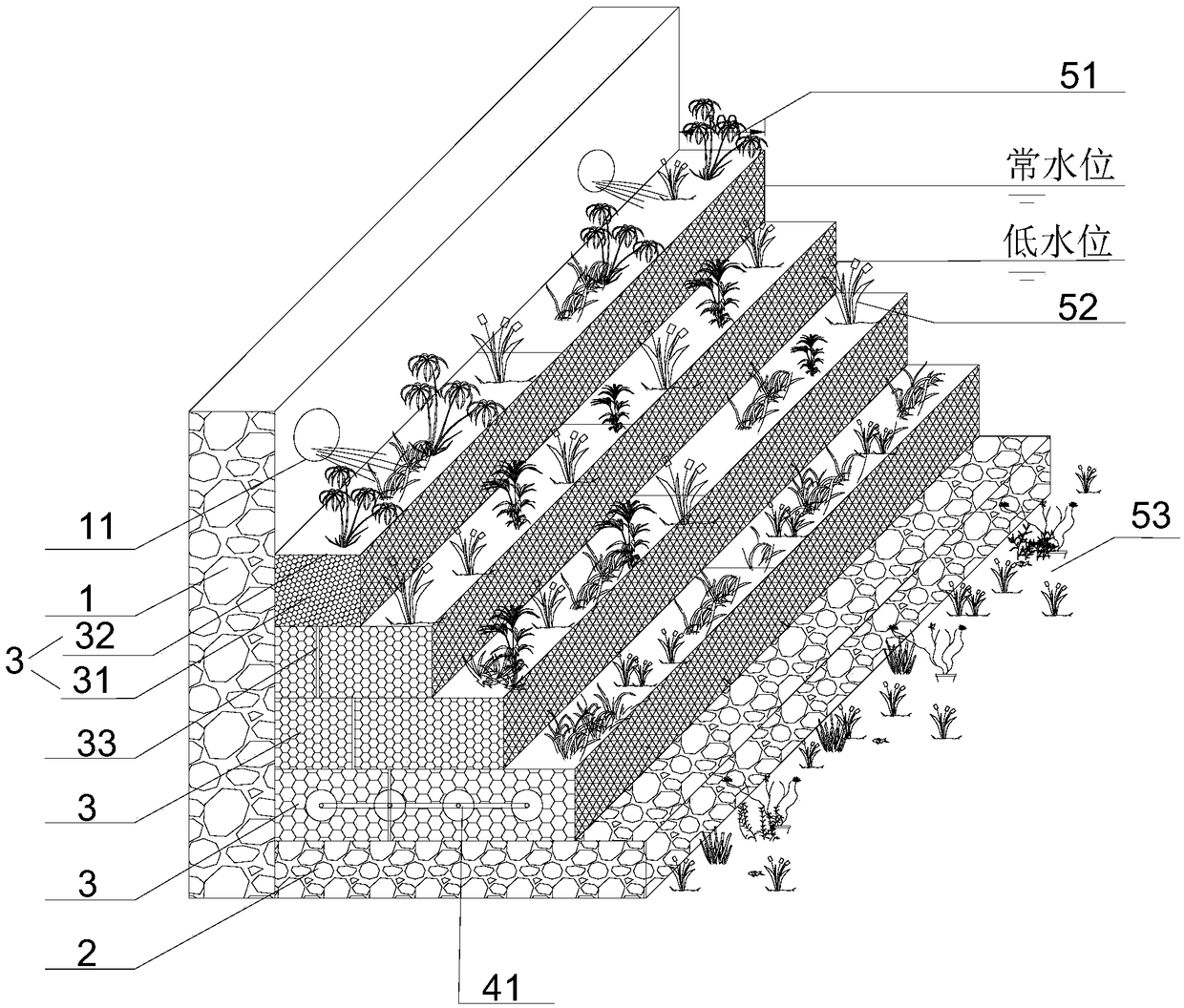

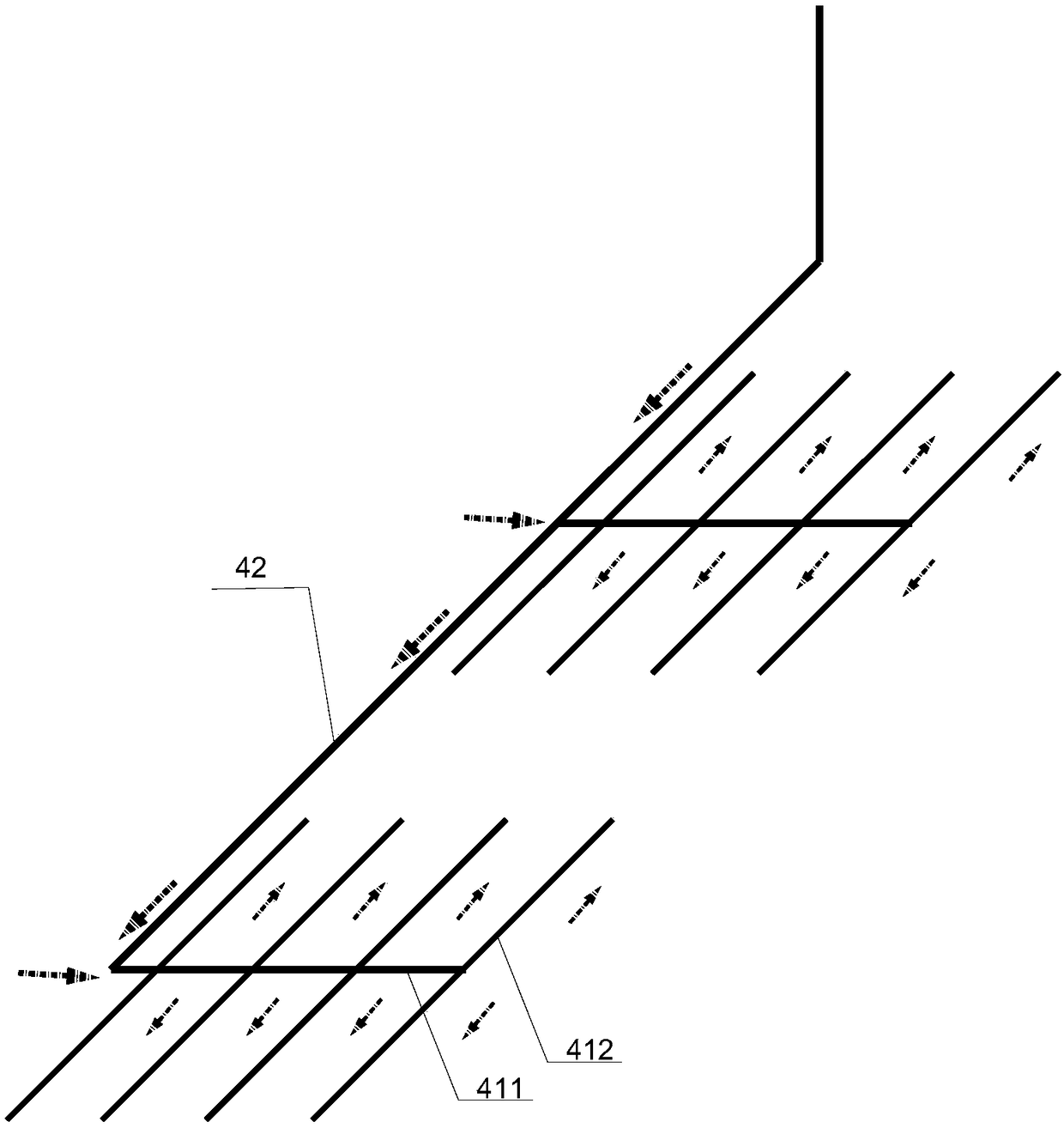

Ecological landscape revetment for river water quality control

PendingCN109368796AIncrease dissolved oxygenGood removal effectHops/wine cultivationCoastlines protectionRiver routingWater quality

The invention relates to an ecological landscape revetment for river water quality control. The ecological landscape revetment comprises an aeration device as well as a base cushion layer and a plurality of module assembling layers which are arranged adjacent to a river revetment and from bottom to top, wherein a staircase structure extending from top to bottom is formed by the base cushion layerand the module assembling layers; each module assembling layer comprises a filler layer and an enclosing support layer surrounding the outer periphery of the filler layer; flow guiding holes are formed in each module assembling layer except the uppermost module assembling layer along the vertical direction and the horizontal direction in a penetrating manner; and the aeration device comprises an aerator on the river bank, an aeration branch pipe embedded in the lowermost module assembling layer and an aeration main pipe in fluid communication with an air outlet of the aerator and an air inletof the aeration branch pipe. The ecological landscape revetment disclosed by the invention not only has the functions of protecting the bank and purifying water, but also has the functions of increasing the dissolved oxygen in the water body through the aeration device and enhancing the pollutant removing effect.

Owner:中建生态环境集团有限公司

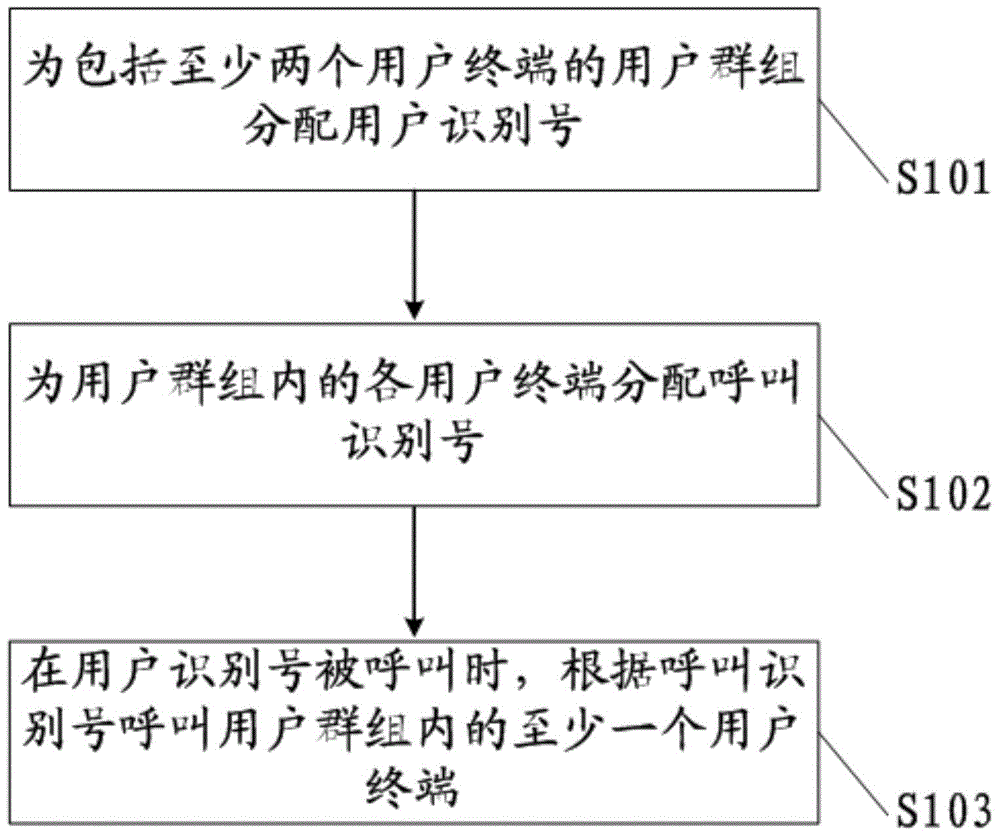

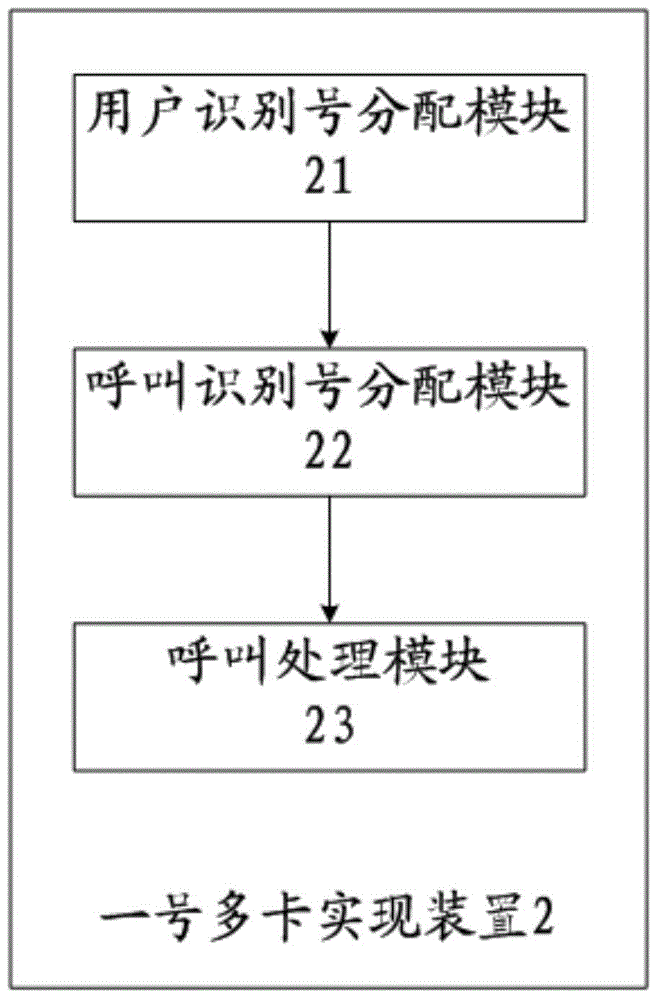

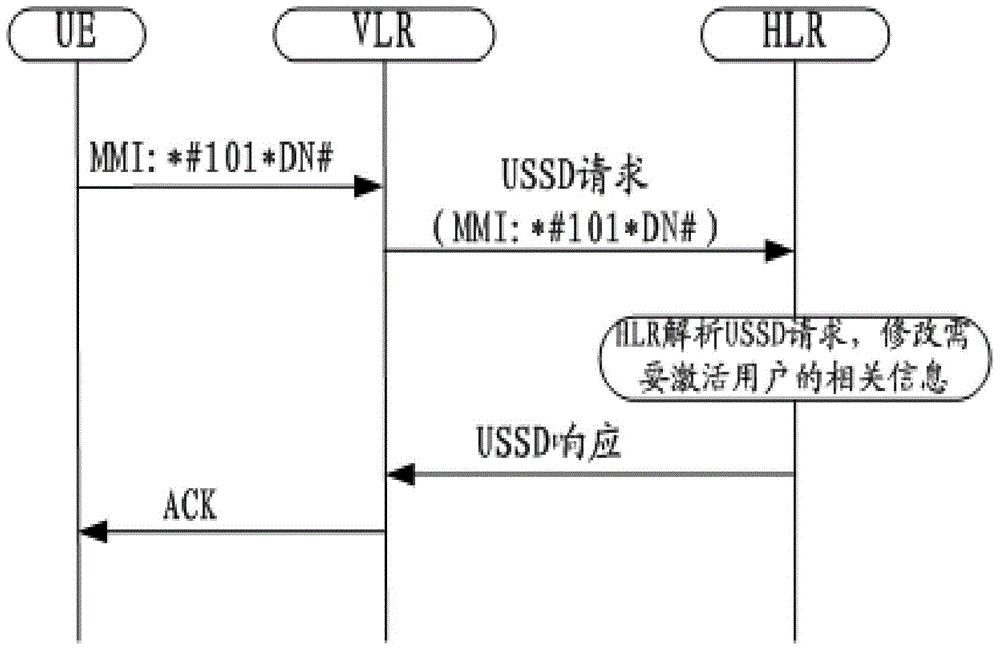

Method and device for realizing a one-number multiple-card technology, home location register and communication system

InactiveCN105530632AReduce use costReduce management and maintenance costsNetwork data managementService providerUser group

The invention provides a method and a device for realizing the one-number multiple-card technology, a home location register and a communication system. The method comprises steps that, a user group including at least two user terminals is distributed with a user identification number; call identification numbers are distributed to each user terminal in the user group; when the user identification number is called, at least one user terminal in the user group is called according to the call identification number. Through the method, the one-number multiple-card technology is realized, multiple user terminals can commonly use one user identification number, use cost of the users is reduced, the quantity of user identification numbers distributed by a service provider is reduced, management and maintenance cost of the service provider are further reduced, and a problem of high cost existing in the one-number one-card technology in the prior art is solved.

Owner:ZTE CORP

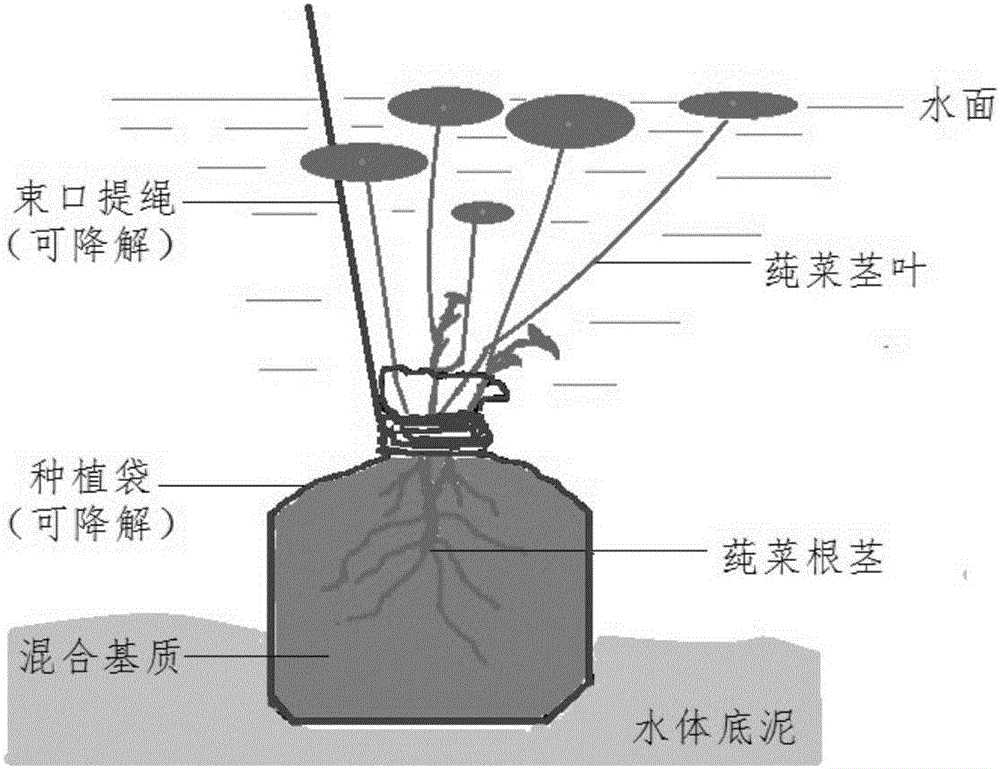

Transplanting method for aquatic vegetable brasenia schreberi

InactiveCN106665104AReduce labor costsImprove rooting rateGrowth substratesCulture mediaEutrophicationSludge

The invention belongs to the technical field of aquatic vegetable planting and particularly relates to a transplanting method for aquatic vegetable brasenia schreberi. The method comprises the following steps: adopting a special degradable planting bag; mixing a base fertilizer, pond sludge and garden soil in a certain ratio and preparing into a matrix; spraying naphthylacetic acid in a certain concentration or rooting powder sold in market onto the roots of brasenia schreberi seedlings or soaking the roots into the naphthylacetic acid or rooting powder; quickly planting into the planting bag on land; compacting the soil and then trussing an upper opening of the planting bag; pulling a pulling rope and carefully sinking the planting bag into a destination water bottom; guaranteeing the upward leaves and stems of the brasenia schreberi. According to the method, a planter does not need to enter water, the labor intensity is effectively relieved and the labor cost is saved; meanwhile, the disturbance to water and bottom sludge is extremely reduced; the seedlings are prevented from floating; the rooting of the brasenia schreberi is boosted; the survival rate of transplanting is increased; the method is beneficial to the quick growth recovery of the brasenia schreberi; the fertility is effectively utilized; the possibility of water eutrophication and moss propagation is reduced; the method is suitable for the brasenia schreberi planters to transplant in large scale and is also suitable for the science researchers to plant in small scale.

Owner:NANJING UNIV

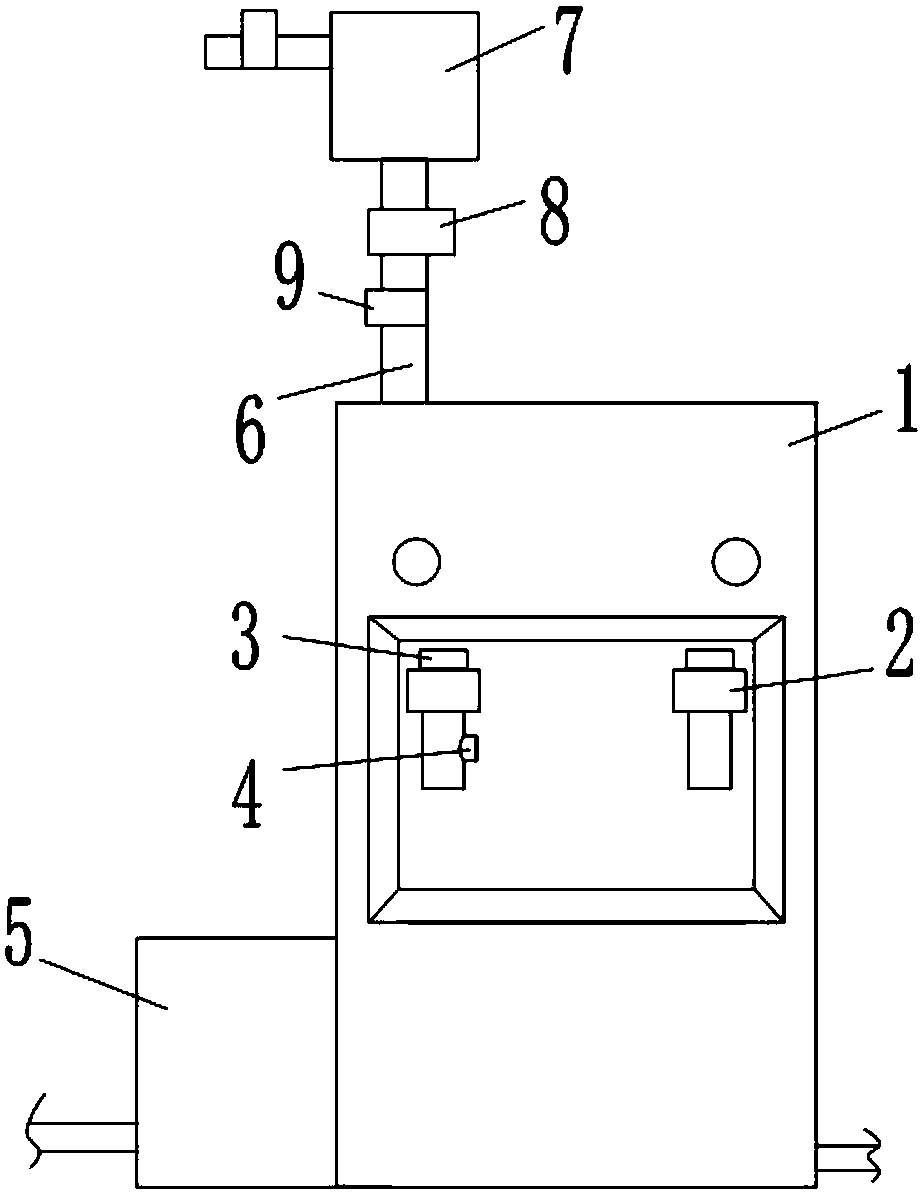

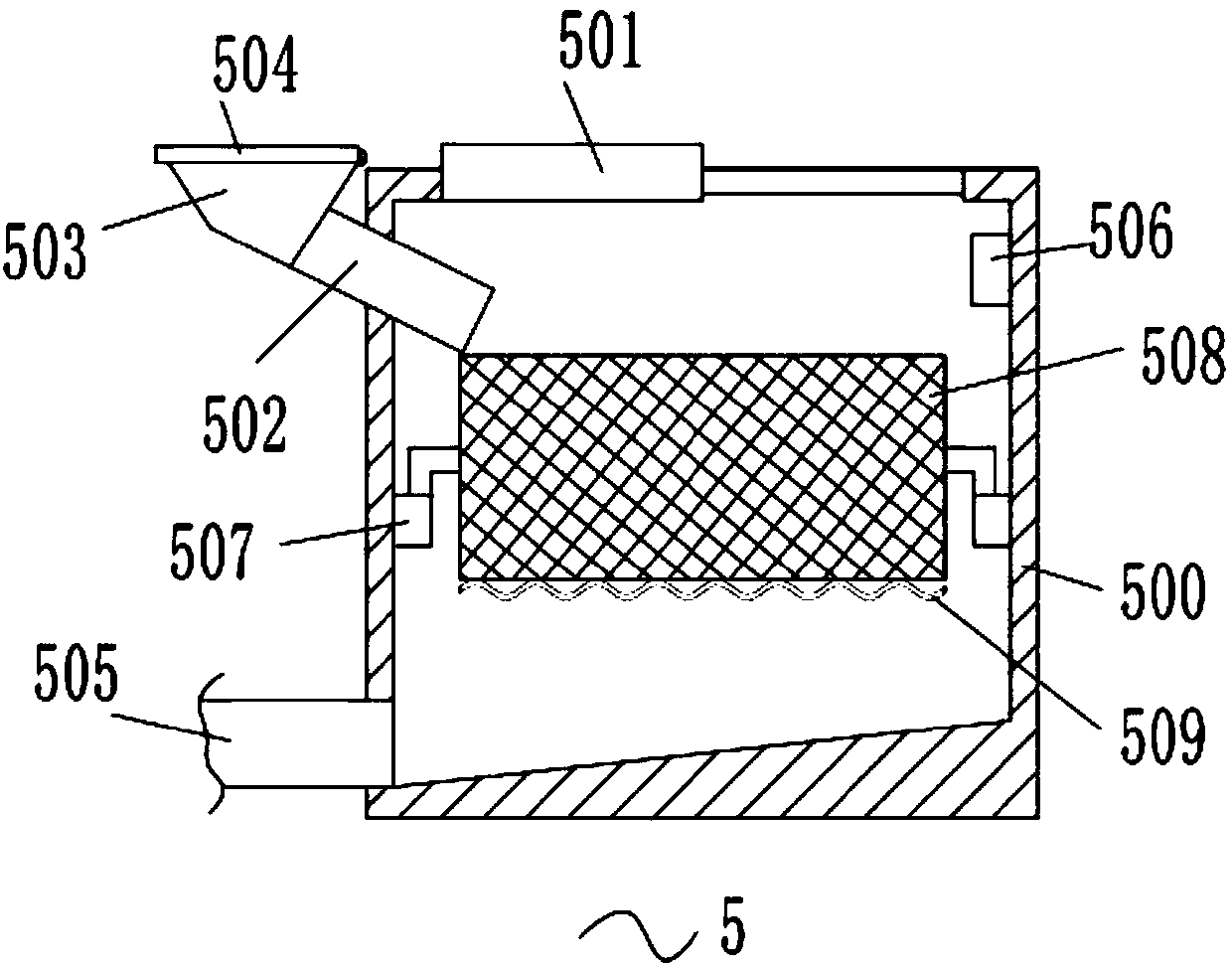

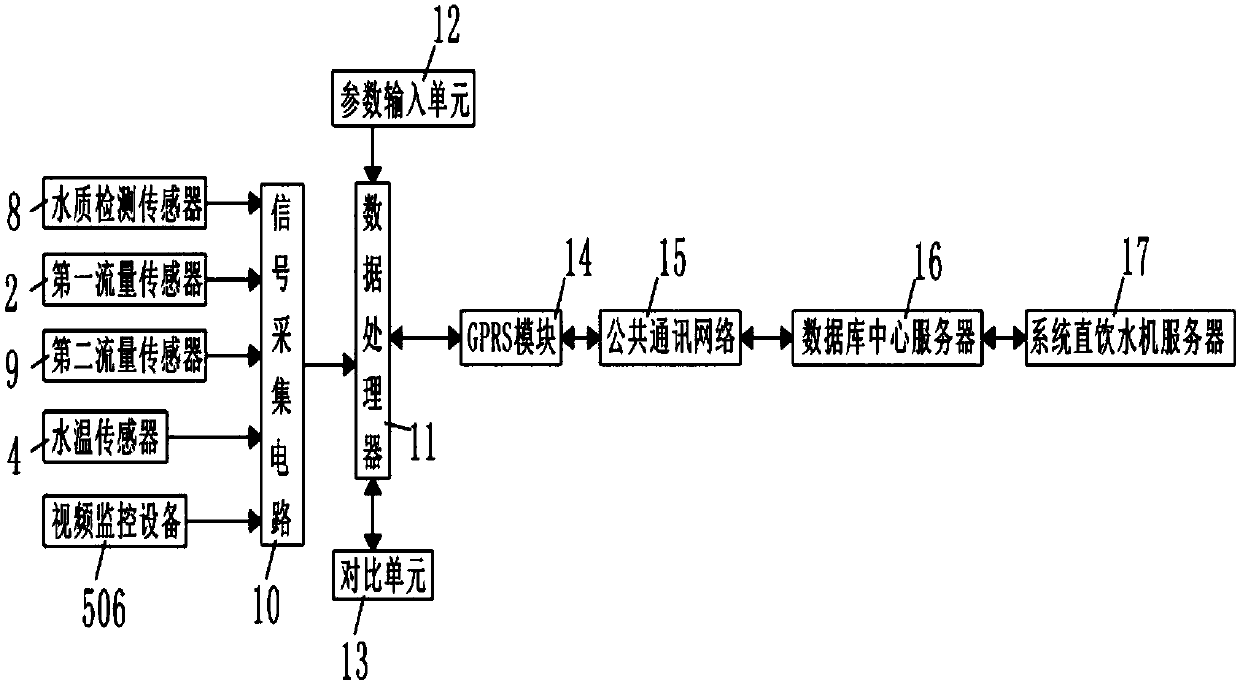

Internet-of-things direct drinking water system

The invention discloses an internet-of-things direct drinking water system, and belongs to the technical field of water fountains. The internet-of-things direct drinking water system comprises a direct drinking water purifier body, wherein a cold / hot water output pipe of the direct drinking water purifier body is provided with a first flow sensor and an infrared induction valve; further, an infrared induction probe of the infrared induction valve is located at the top of the surface of a shell of the direct drinking water purifier body; a hot water output pipe of the direct drinking water purifier body is provided with a water temperature sensor; the left side of the direct drinking water purifier body is provided with a tea oven-drying device; the top of the direct drinking water purifierbody is provided with a water inlet pipe; the top of the water inlet pipe is provided with a tap water purification device. The real-time monitoring and management on the equipment running state, theequipment failure condition and the like of each direct drinking water purifier are realized; meanwhile, hot water is controlled by utilizing the infrared induction valve to flow out; a child is prevented from using the internet-of-things drinking water system in the condition of being not accompanied by an adult; a scald is avoided; the manual participation is reduced; the management and maintenance times are reduced; thus, the management and maintenance costs are decreased and the market application prospect is wide.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

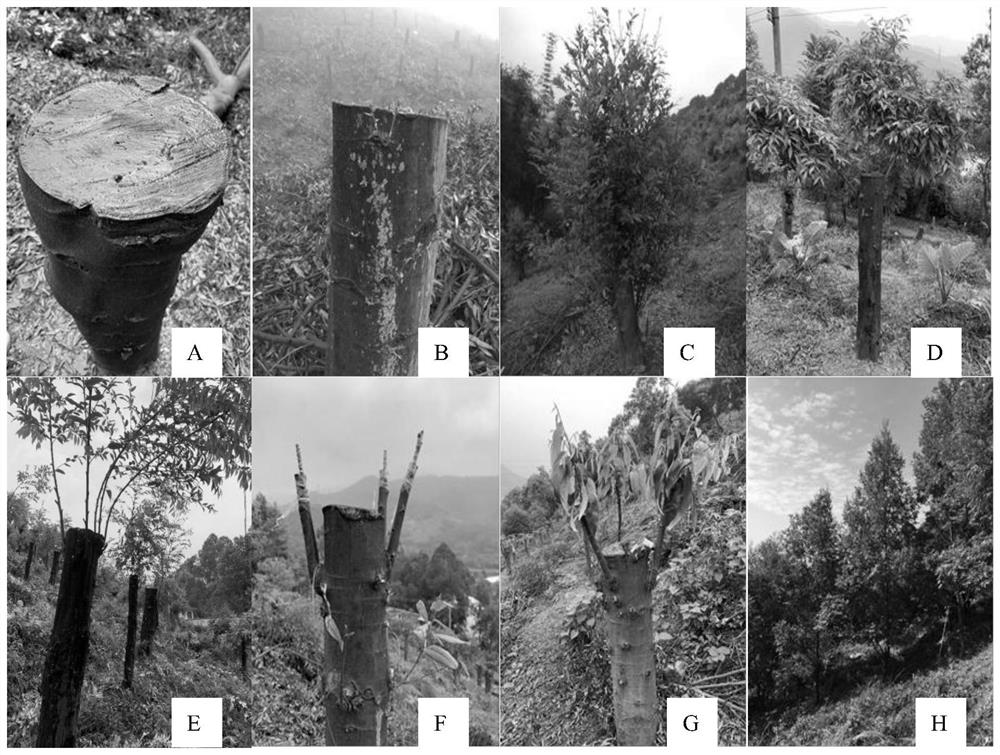

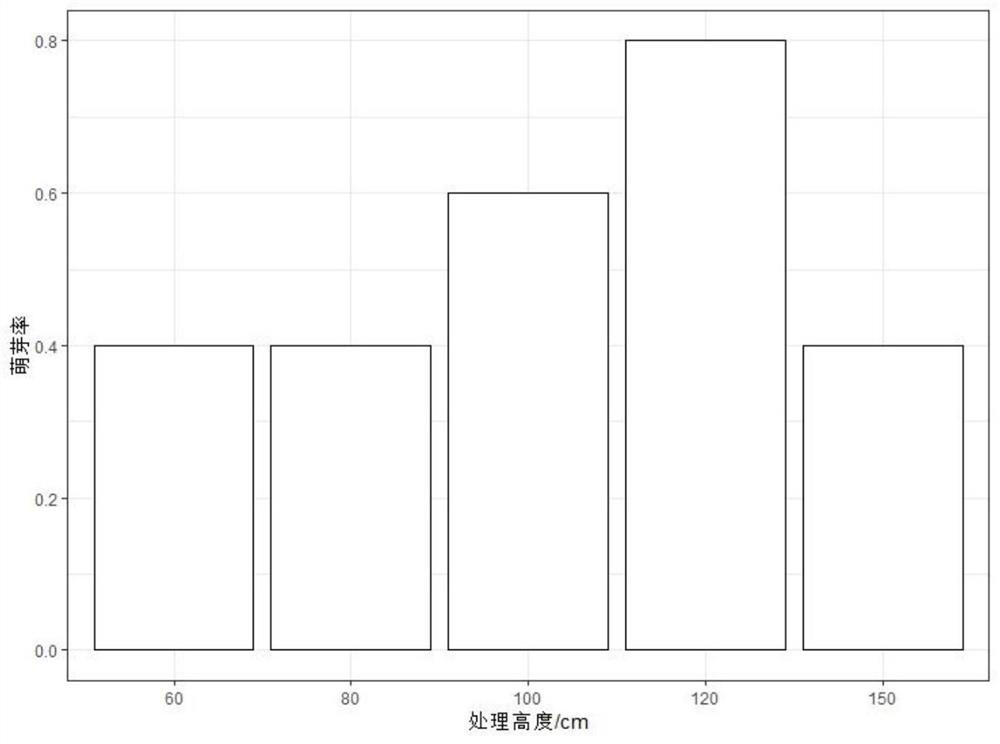

Method for quickly establishing clonal seed orchard of Castanopsis hystrix and application of method

ActiveCN111837791AQuick buildGuarantee the vitality of forest standsGraftingFertilising methodsYoung treeRootstock

The invention provides a method for quickly establishing a clonal seed orchard of Castanopsis hystrix and application of the method, and belongs to the technical field of forest tree breeding. The method for quickly establishing the clonal seed orchard of Castanopsis hystrix includes the steps: selecting forest stand, cutting stems for promoting sprouting, treating rootstocks, selecting parent materials, collecting scions, performing top grafting and carrying out later management. For the first time, Castanopsis hystrix trees of 5-10 years are adopted as rootstocks, fast-growing high-quality scions suitable for orchard construction are selected as materials in consideration of genetic distance and the ratio of male flowers to female flowers, and the excellent clonal seed orchard can be established quickly through a matched grafting technology which is obtained through careful exploration and design. The method is different from previous grafting which is based on seedlings or saplings,through the scheme, the flowering time is shortened quickly, early fruiting is promoted, and the forest can be formed quickly; and the stand viability of the seed orchard is ensured, and efficient productivity of high-quality seeds is ensured.

Owner:GUANGDONG ACAD OF FORESTRY

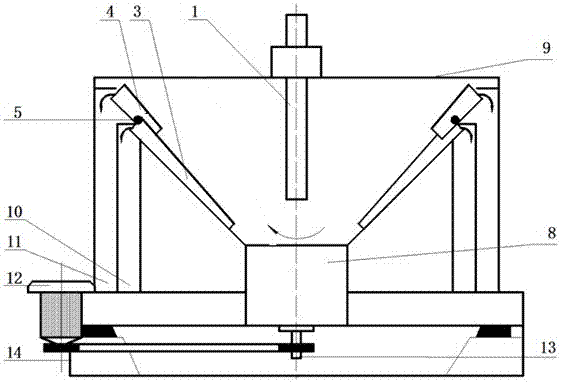

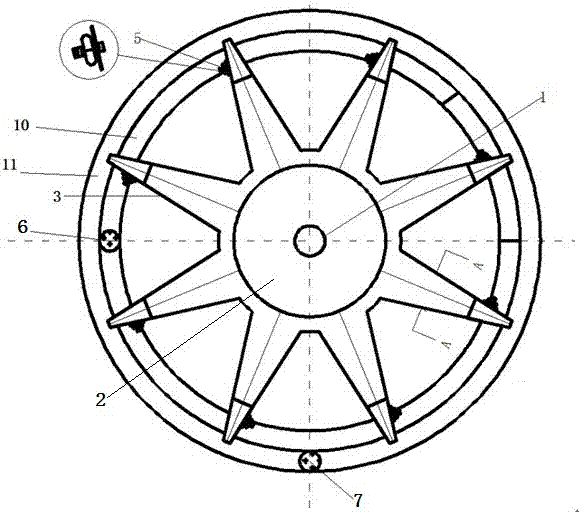

Tapered centrifugal beneficiation equipment

ActiveCN106925436APromote loosePromote stratificationRotary centrifugesElectric machineClassical mechanics

The invention discloses tapered centrifugal beneficiation equipment. The tapered centrifugal beneficiation equipment comprises a central ore feeding pipe, a centrifugal rotating drum, shunting grooves, intercepting grooves, a hollow shaft rotating platform, a shell, a concentrate groove, a tailing groove, a driving motor, a hollow shaft and a machine frame, wherein the centrifugal rotating drum, the intercepting grooves, the hollow shaft rotating platform, the concentrate groove and the tailing groove are arranged in the shell, the centrifugal rotating drum is located in the center of the interior of the shell, the central ore feeding pipe penetrates through the shell from outside to be right opposite to the bottom of the centrifugal rotating drum, the shunting grooves are uniformly formed in the periphery of the centrifugal rotating drum, the intercepting grooves are formed in the tail ends of the shunting grooves, the concentrate groove is formed in the outlets of the shunting grooves, the tailing groove is formed in the outlets of the intercepting grooves, the centrifugal rotating drum is arranged on the hollow shaft rotating platform, the hollow shaft rotating platform is connected with the hollow shaft, the hollow shaft is connected with the driving motor, and the driving motor is arranged on the machine frame. The tapered centrifugal beneficiation equipment is environment-friendly, efficient, energy-saving, capable of automatically and continuously discharging concentrate and tailings, high in efficiency, low in cost and suitable for high-efficiency sorting of fine-grain mineral so that the sustainable development of resources can be realized.

Owner:KUNMING UNIV OF SCI & TECH

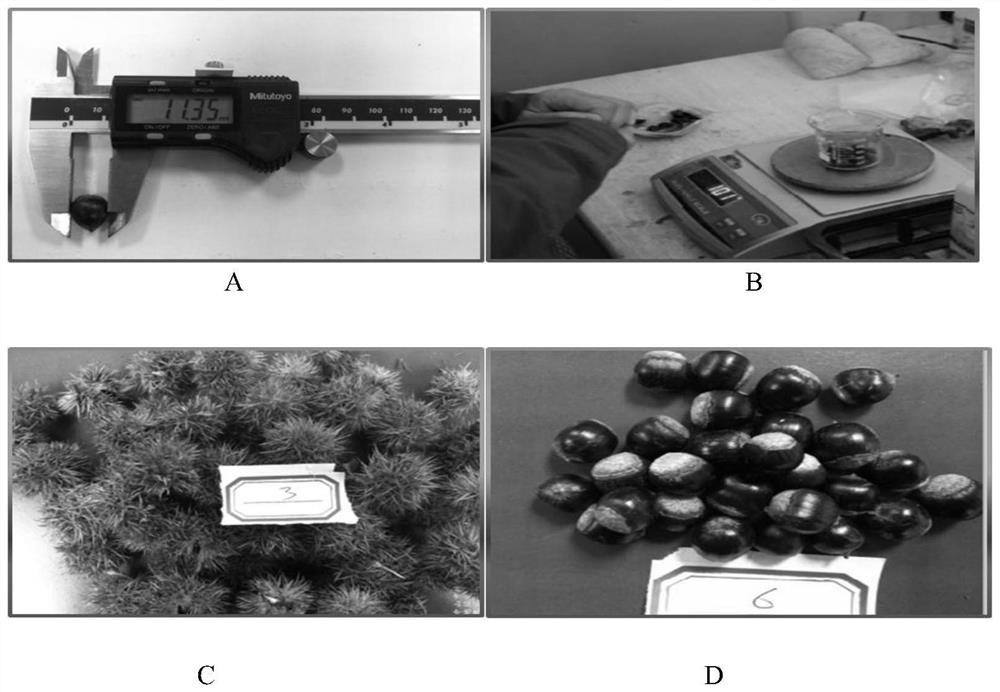

Method for commercialized cultivation of container seedling of cold-resistant japanese cinnamon germplasm

InactiveCN102550271AMeet production quarantine requirementsIncrease commodity rateClimate change adaptationCultivating equipmentsGermplasmGreening

The invention relates to a method for commercialized cultivation of container seedling of cold-resistant japanese cinnamon germplasm. During the process of culturing seedlings, the requirements for the technical links such as seed harvesting, storing, matrix sterilizing and the like are strict; according to the features of different stages of container seedling cultivation, the method of the invention adopts the technical scheme of rational base fertilizer, foliage dressing, water treatment, pruning and so on; and the configuration materials of the matrix are easily-accessible, and are low in cost, and the seedlings have good growth adaptability and grow fast. According to the growth characteristics of japanese cinnamon, the method of the invention divides the container seedling cultivating into two stages so as to effectively avoid the possible damages to the seedlings caused by low temperature in winter and effectively increase the growth speed of the seedlings. The method of the invention uses the technical indicators of seedling age, shape, physiology and so on as the basis, determines the quality grade of seedlings of different usages, reduces the application cost of afforestation and greening, and improves the application effects.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

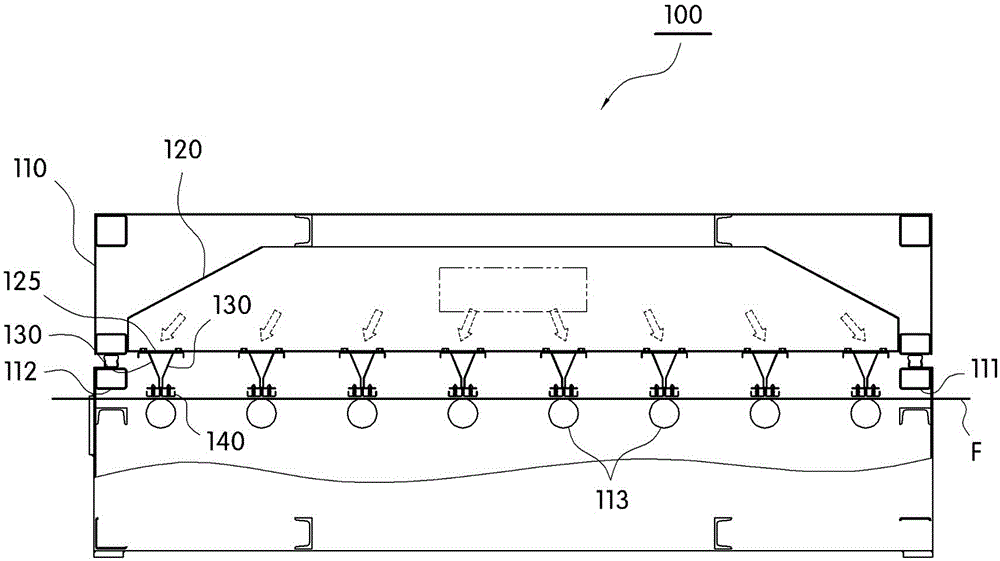

Hot air drier having a variance nozzle

InactiveCN105013679AAdjust dischargeAdjust up and down intervalDrying solid materials with heatDrying gas arrangementsInterior spaceEngineering

The invention relates to a hot air drier having a variance nozzle. The hot air drier includes: a drying oven, coated with a film coating solution to a predetermined thickness in one direction through the drying oven; an inner chamber disposed within an interior space of the drying furnace, and is filled by hot air supplied from the outside; a first nozzle , which is detachably assembled within the interior chamber, so that the first inlet is formed in the through the internal chamber of the plurality of hot air supply ports communicating; a second nozzle, having a second inlet in order to be able to move inserted in a manner corresponding to the first nozzle extends a predetermined length from the first discharge port, and communicates with the first nozzle to the outlet through the second coated with the coating solution to the film side injection of hot air; and a nozzle adjusting portion, a second nozzle disposed in a first adjustment screw, a first adjustment screw, disposed in the through hole formed in a first regulating nozzle of the first, with respect to the first nozzle portion to change the position of the second nozzle nozzle adjustment to adjust the interval between the second nozzle and the film.

Owner:PROTEM

Rapid green-recovering method for ground cover plants in mountain forests

InactiveCN108575170AEnhance layeringRich landscaping effectPlant cultivationCultivating equipmentsWater storageSlope length

The invention relates to a rapid green-recovering method for ground cover plants in mountain forests, and belongs to the technical field of green recovery in the mountain forests. A concept of ''storage and seepage'' in a sponge city is applied to the method, water storage grass ditches are arranged according to different slope lengths and slope degrees of mountain slopes, different plats are sequentially planted in the mountain slopes in the mountain forests from the top to the bottom, and the drought-tolerant moisture-tolerant dwarf plants or ground cover plants are planted in the water storage grass ditches. The method provided by the invention has the advantages of simple construction, a wide applicable region, low investment costs, a quick effect, convenient later management, and easycopying and promotion.

Owner:WUXI MISHO ECOLOGY LANDSCAPE

Method for promoting healing of cuttings of southern pines in high temperature seasons

ActiveCN104823629APromote early healingSlow physical activityHorticultureSkin callusObserved Survival

The invention discloses a method for promoting healing of cuttings of southern pines in high temperature seasons. Temperature of upper portions of the cuttings is artificially decreased to be lower than that of lower portions of the cuttings so as to promote advance healing of the cuttings. Experiments prove that when the method is adopted for pine cutting pretreatment, callus tissues can be formed in 20-25 days, rooting induction from the callus tissues needs about 20 days, the accumulated rooting time of the cuttings is 43-46 days, which is 14-17 days shorter compared with the traditional method. Meanwhile, parts with leaves in the low temperature environment are slow in physiological activities, and water demand and rate of infection are obviously reduced, thereby greatly saving management and protection cost. The method is economically efficient and easy to operate, solves the problems of large management and protection difficulty and low survival rate of cuttings of southern pines in high temperature seasons, is applicable to being popularized and used in production units of cutting propagation of southern pines, and has an important practical importance for scaled cutting propagation of southern pines.

Owner:GUANGXI FORESTRY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com