Tapered centrifugal beneficiation equipment

A mineral processing equipment and shrinkage technology, which is applied in the field of tapered flow film centrifugal mineral processing equipment and tapered centrifugal mineral processing equipment, can solve the problems of poor separation effect, low mineral processing capacity, and low enrichment ratio, etc., to achieve The separation effect is remarkable, the sorting time is shortened, and the application range is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

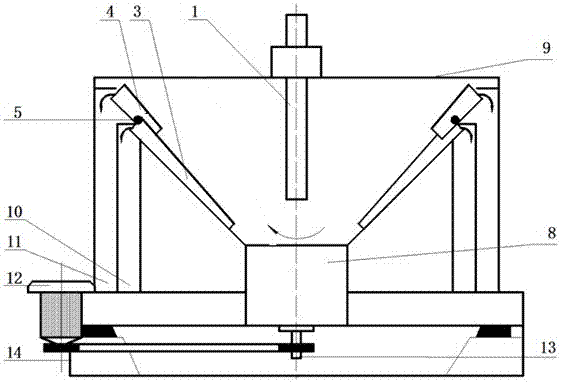

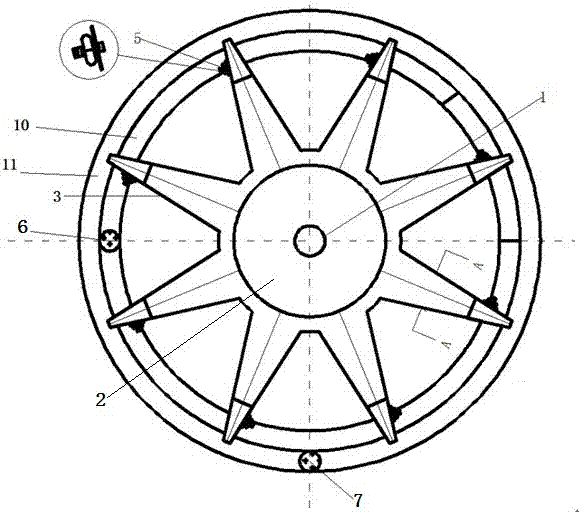

[0035] A kind of sharp-shrinking centrifugal beneficiation equipment, such as figure 1 , 2 , 3, and 4, including central ore feeding pipe 1, centrifugal drum 2, diverter tank 3, interceptor tank 4, hollow shaft rotating platform 8, shell 9, concentrate tank 10, tailings tank 11, drive motor 12, Hollow shaft 13, frame 14; centrifugal drum 2, interception tank 4, hollow shaft rotating platform 8, concentrate tank 10, tailings tank 11 are set inside the shell 9, centrifugal drum 2 and hollow shaft rotating platform 8 are located in the shell 9 center, the center of the bottom of the centrifugal drum 2 is connected with a hollow shaft rotating platform 8, and the central ore feeding pipe 1 passes through the shell 9 from the outside and faces the bottom of the centrifugal drum 2, so that minerals can be fed from the upper end of the central feeding pipe 1. into the bottom of the centrifugal drum 2, eight shunt grooves 3 are evenly arranged around the side wall of the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com