Method for promoting healing of cuttings of southern pines in high temperature seasons

A cutting and high temperature technology, which is applied in the field of southern pine cutting propagation, can solve problems such as high temperature, low survival rate, and small temperature difference between day and day

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

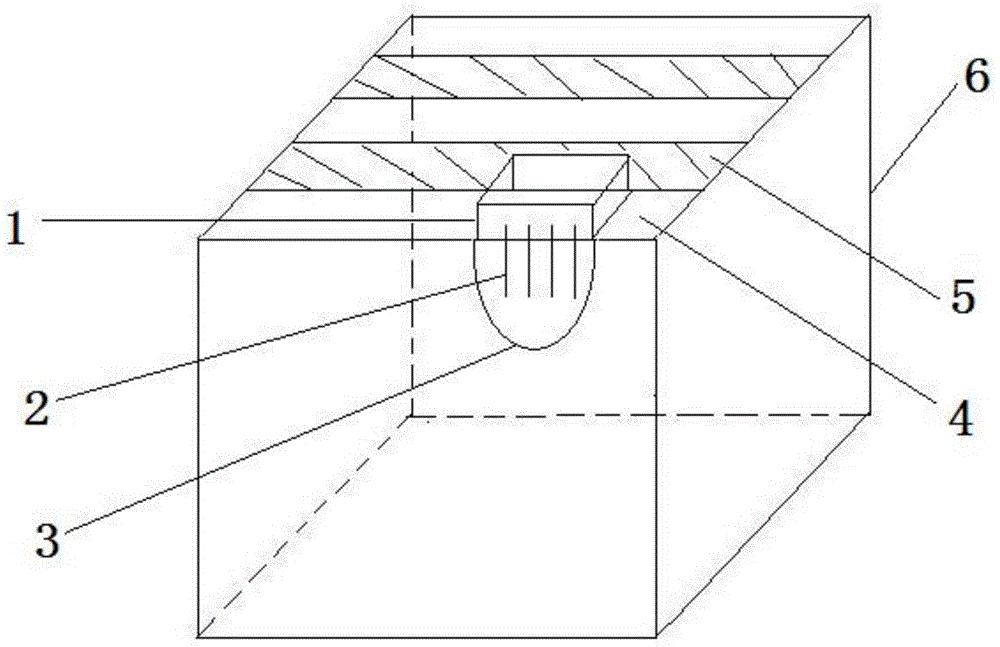

[0023] Renovation of the freezer door—cut the glass door (100cm×60cm) of the horizontal freezer into 3 strip-shaped openings (100cm×9.5cm) according to the size of the cutting container, so that the edge of the cutting container is just stuck in the freezer after being inverted Outside the glass door; add aluminum alloy to the 3 glass strips cut out, and the freezer door can be restored without wound induction;

[0024] Cutting container—choose a transparent disposable plastic box of 15cm×10cm×5cm, and use a puncher to punch one hole every 5cm on the five sides of the plastic box except the top surface (3 holes on the long side, 2 holes on the wide side, 1 hole on the high side, a total of 12 holes) in order to ventilate and replenish water, fill the container with moist coconut peat and compact it, and seal the container with plastic film;

[0025] Cuttings——on July 5, 2014, select semi-lignified masson pine cuttings, cut the incision, soak in water for 12 hours to remove ...

Embodiment 2

[0030] same as embodiment 1

[0031] same as embodiment 1

[0032] Cuttings——on August 5, 2014, select semi-lignified slash pine cuttings, cut flat cuts, soak in water for 10 hours to remove turpentine, soak in IBA solution with a concentration of 500ppm for 1 hour, and then soak in 0.3% carbendazim for 8 minutes. Insert the cuttings into the cutting container prepared in step , cut 60 cuttings in a plastic box, and the cutting depth is 4.5cm (requires a successful cutting, repeated cuttings will loosen the matrix and cause the cuttings to not be fixed when inverted), Spray the needles of the cuttings with spray, spray a layer of wet mist on the inner layer of the black film (it is better not to drip water) and cover the cuttings. The distance between the black film and the cuttings is 10cm, and the bag of the black film is fixed on the plastic box with a rubber band. mouth;

[0033] same as embodiment 1

[0034] same as embodiment 1

[0035] Field cuttings - After p...

Embodiment 3

[0037] same as embodiment 1

[0038] same as embodiment 1

[0039] Cuttings——on September 3, 2014, select semi-lignified slash pine cuttings, cut the incision, soak in water for 12 hours to remove turpentine, soak in IBA solution with a concentration of 300ppm for 2 hours, and then soak in 0.1% carbendazim for 10 minutes. Insert the cuttings into the cutting container prepared in step , cut 65 cuttings in a plastic box, and the cutting depth is 4cm (successful cutting is required once, repeated cuttings will loosen the substrate and the cuttings cannot be fixed when inverted), spray Spray the needles of the cuttings with moisture, spray a layer of wet mist on the inner layer of the black film (it is better not to drip water), and then cover the cuttings. The distance between the black film and the cuttings is 10cm, and the black film bag is fixed on the mouth of the plastic box with a rubber band. ;

[0040] same as embodiment 1

[0041] same as embodiment 1

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com