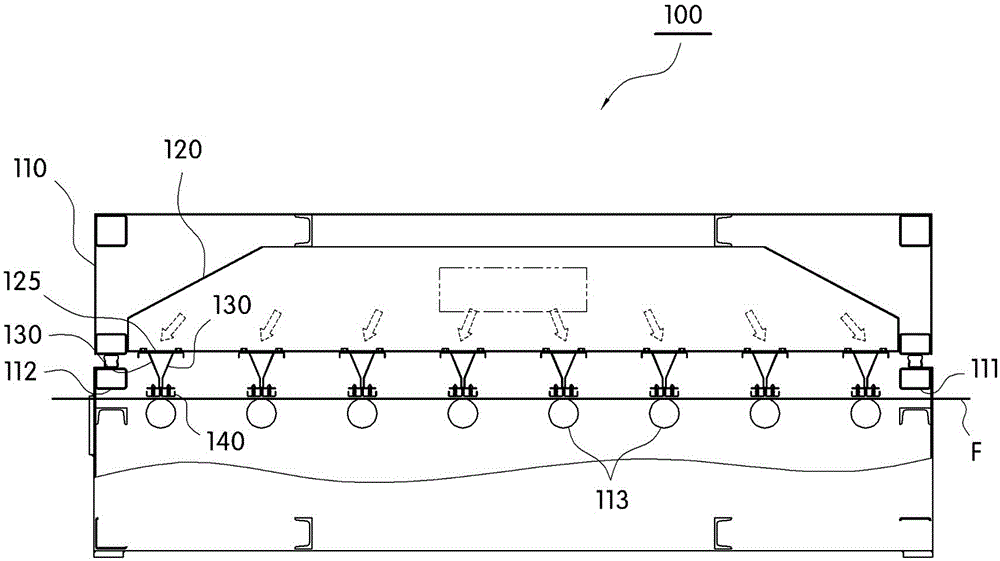

Hot air drier having a variance nozzle

A technology of hot air dryer and discharge port, applied in the direction of heating to dry solid materials, dryers, drying solid materials, etc., can solve problems such as difficulty in preventing product defects, changing spray conditions, drying efficiency restrictions, etc., to reduce management and maintenance. cost, improve product yield, and prevent adverse effects of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

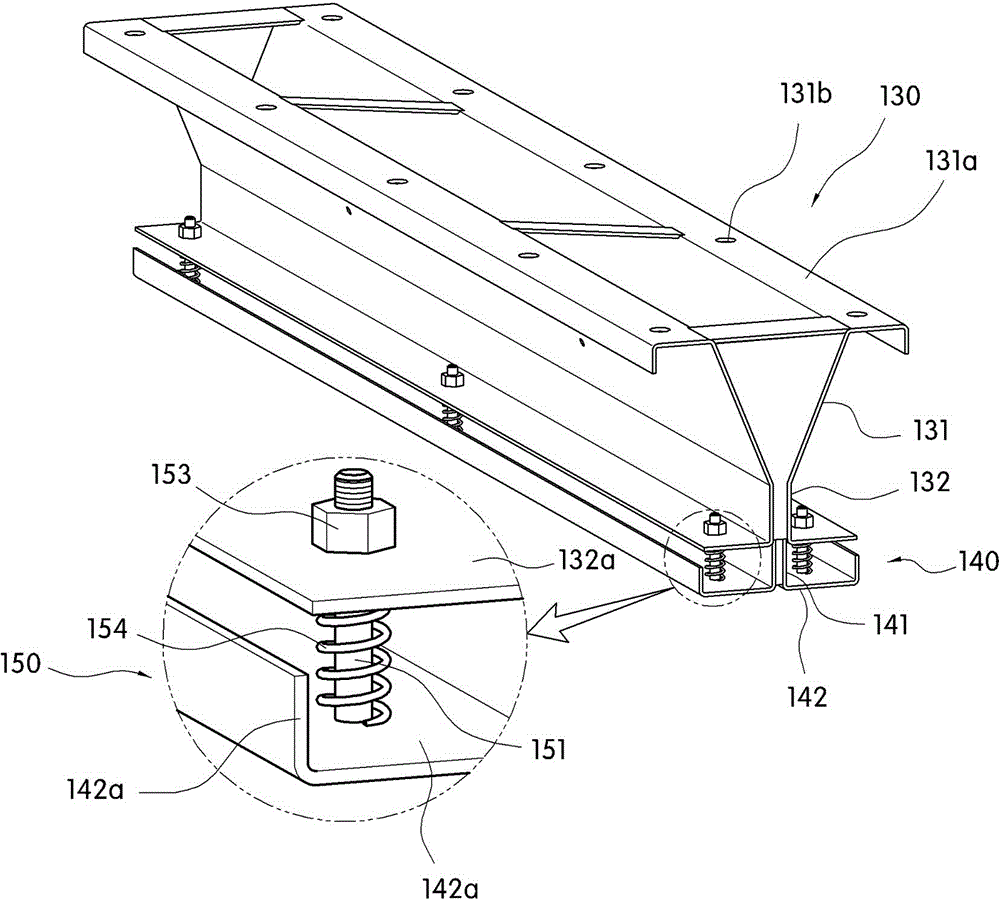

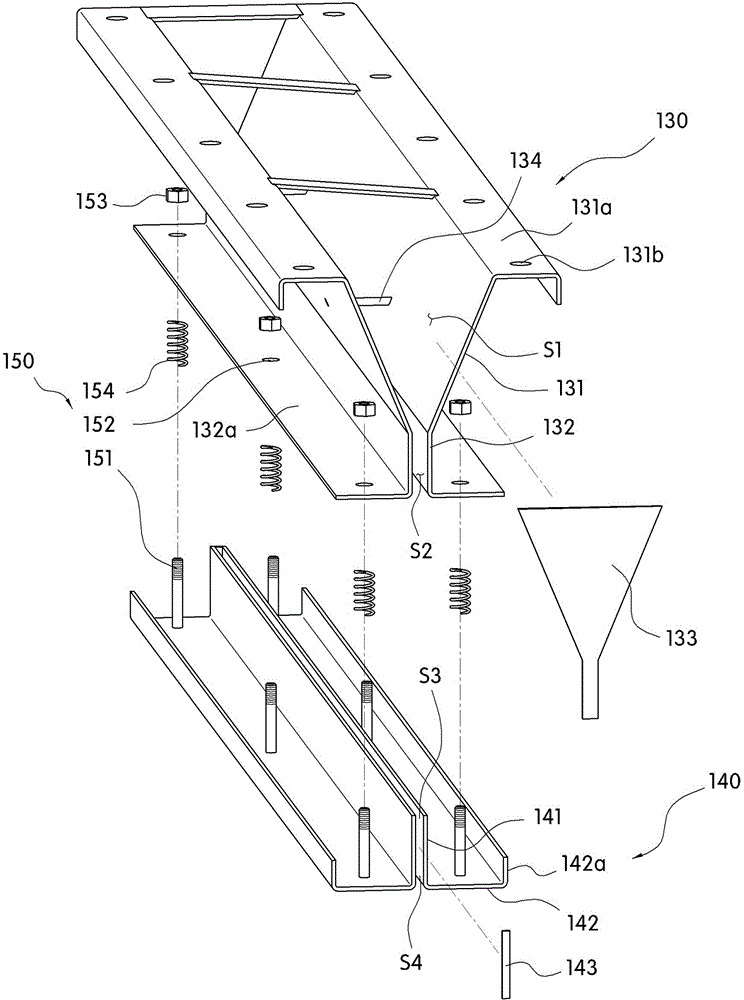

Embodiment Construction

[0052]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily implement the present invention. However, in the process of explaining the structural principles of the preferred embodiments of the present invention in detail, if it is judged that the specific description of the relevant known functions or structures will unnecessarily obscure the gist of the present invention, the detailed description will be omitted. .

[0053] Also, throughout the drawings, the same reference numerals are used for parts that perform similar functions and actions.

[0054] In addition, throughout the specification, when it is stated that one part is "connected" to another part, this includes not only the case of "direct connection" but also the case of "indirect connection" via other elements therebetween. Also, when it is indicated that a part "includes" a structural element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com