Anti-corrosion anti-seepage layer and manufacturing method thereof

A production method and technology for an anti-seepage layer, which are applied in anti-corrosion coatings, coatings, earth-moving drilling and mining, etc., can solve the problems of poor anti-corrosion and anti-seepage performance, complicated construction steps, single materials, etc., and improve transportation efficiency. Dense, excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

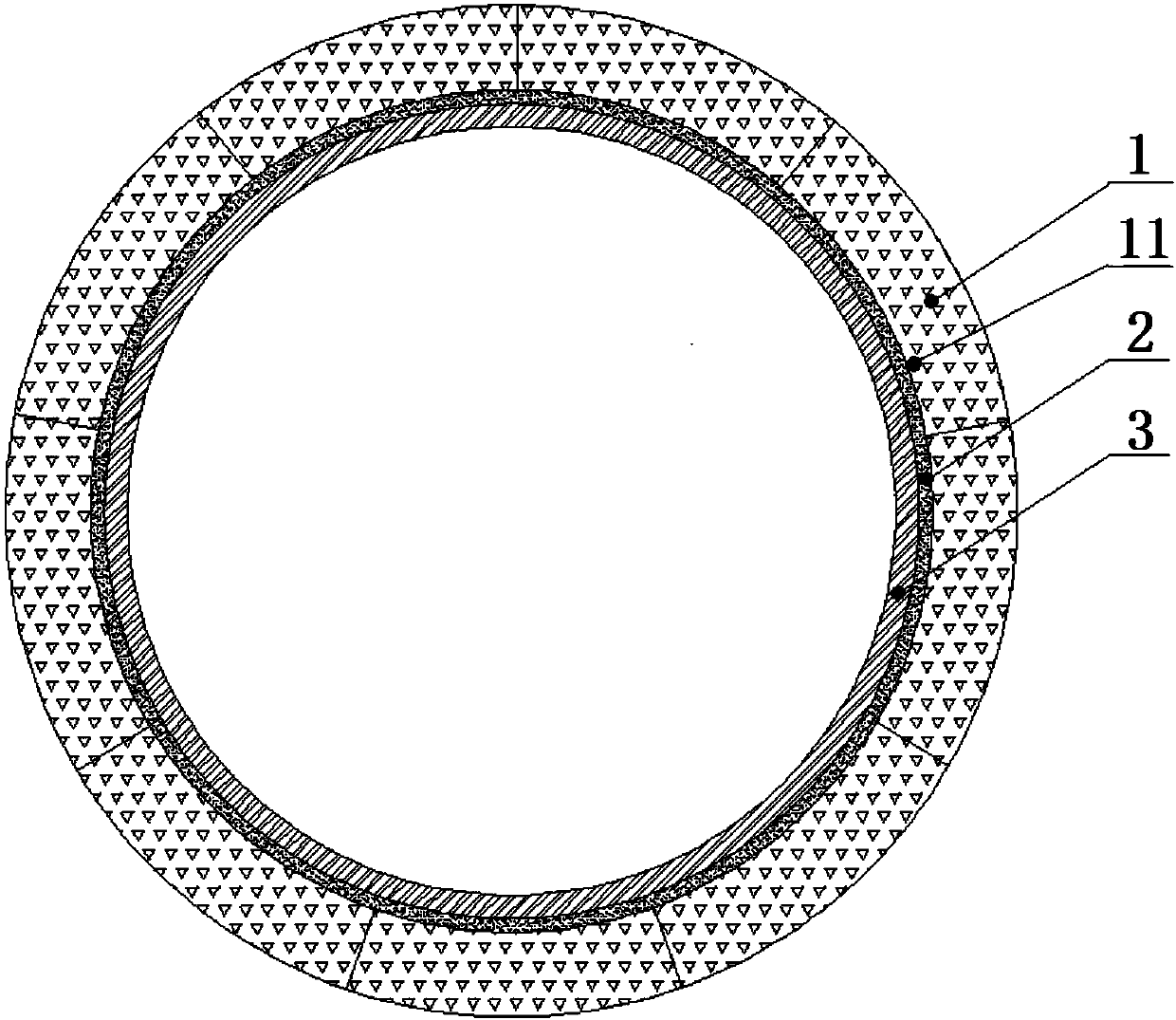

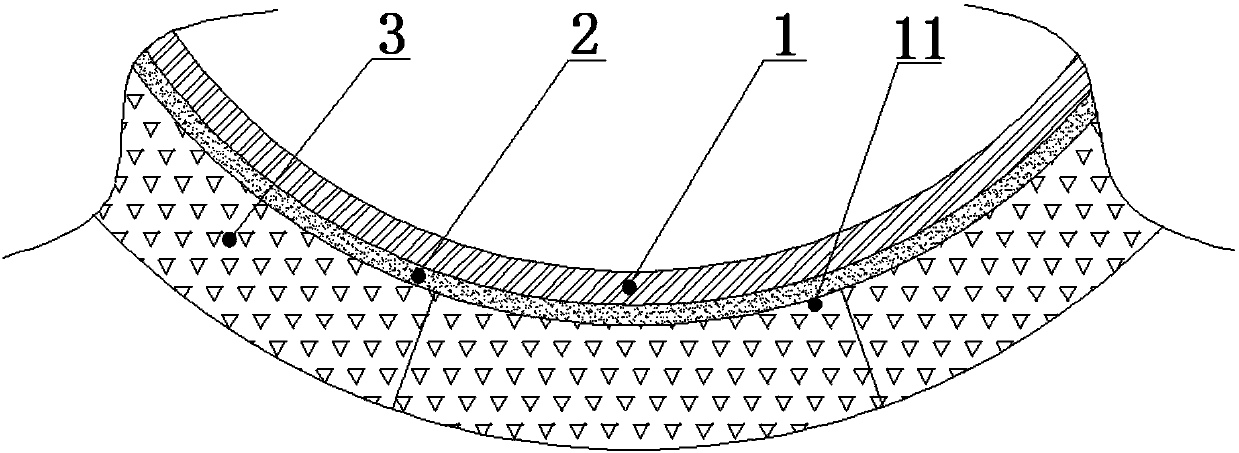

[0028] refer to figure 1 with figure 2 , in this embodiment, an anti-corrosion and anti-seepage layer is provided, and the anti-corrosion and anti-seepage layer is used as the inner lining structure of the circular tubular member 1 . The anti-corrosion and anti-seepage layer includes a bottom layer 2 attached to the component 1 and a surface layer 3 attached to the bottom layer 2 . Wherein, the bottom layer material forming the bottom layer 2 includes MMA waterproof material, that is, the bottom layer material may only be composed of MMA waterproof material, or may be mainly composed of MMA waterproof material. The surface layer material forming the surface layer 3 includes enamel, that is, the surface layer material can be composed only of enamel, or mainly composed of enamel.

[0029] Among them, the MMA waterproof material has good waterproof performance on the one hand, so that the anti-corrosion and anti-seepage layer can obtain good impermeability; on the other hand, ...

Embodiment 2

[0038] This embodiment provides a method for manufacturing the anti-corrosion and anti-seepage layer in Embodiment 1, which includes a surface treatment step, a bottom layer material coating step and a surface layer material coating step performed in sequence.

[0039] Firstly, the surface treatment step is carried out on the base surface 11 of the component 1 (the surface on which the anti-corrosion and anti-seepage layer needs to be attached), so that the roughness of the base surface 11 is within the range of CSP3-CSP5, so as to increase the bottom layer formed by subsequent coating The bonding force with the base surface 11 improves the firmness of the connection between the anti-corrosion and anti-seepage layer and the base surface 11.

[0040] Specifically, the surface treatment step includes the following sub-steps:

[0041] S1. Use mortar to repair the recesses on the base surface 11 (including but not limited to inner wall joints, holes, etc.), and the aggregate parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com