Environment-friendly polyurethane surface lacquer enamel

A polyurethane, environmentally friendly technology, applied in the field of enamel paint, can solve the problems of poor weather resistance and wear resistance, and achieve the effects of high environmental protection, high wear resistance and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] An environment-friendly polyurethane surface enamel, comprising hydroxyacrylic resin, biuret, non-heavy metal pigment, butyl acetate, and low-distillation range aromatic hydrocarbon solvent, wherein the weight percent content of each component is respectively: the described hydroxyacrylic resin is 50%, the biuret is 15%, the non-heavy metal pigment is 20%, the butyl acetate is 10%, and the low-distillation aromatic hydrocarbon solvent is 4.95%.

[0009] The distillation range of the low-distillation-range aromatic hydrocarbon solvent is 155-175°C.

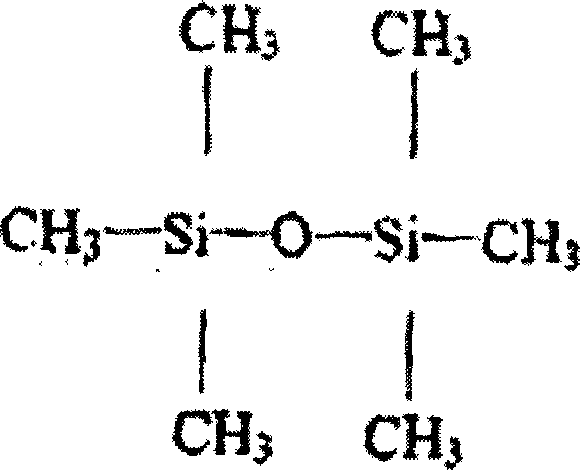

[0010] In the present invention, chemical additives that do not affect its performance can be added, such as adding 0.05% by weight of hexamethyldisiloxane as a leveling agent. Methyldisiloxane is commonly known as silicon ether, and its molecular formula is: (CH 3 ) 3 SiOSi (CH 3 ) 3 , its structural formula is as follows:

[0011]

[0012] Methyldisiloxane can increase the compatibility of polyurethane slurry and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com