Steel for enamel heat transfer element having corrosion resistance and manufacturing method thereof

A heat transfer element and corrosion resistance technology, applied in the field of steel materials, can solve the problems of enamel surface defects, reduced service life, devitrification, etc., and achieve the effect of good corrosion resistance, high corrosion resistance, and resistance to sulfuric acid dew point corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In order to solve the technical problem that the enamel heat transfer element in the prior art may produce enamel surface defects during the manufacturing process, and local chipping or devitrification may occur during installation and use, which greatly reduces the service life. A corrosion-resistant steel for enamel heat transfer elements is provided. The steel plate itself has good corrosion resistance, and at the same time, the surface of the steel plate can be coated with enamel. The enamel heat transfer element manufactured by using the steel plate of the present invention has no scale explosion and enamel adhesion Good, low pinhole rate, and still has good corrosion resistance under the condition of partial enamel damage.

[0028] The weight percent of the chemical composition of the steel for the enamel heat transfer element is: C≤0.010%, Mn0.40-0.60%, Si≤0.10%, P≤0.02%, S≤0.02%, Als0.02%-0.06%, Cu0.20%~0.40%, Cr0.70%~1.10%, Sb0.04%~0.10%, Ti0.02%~0.05%, Nb0.01%...

Embodiment 2

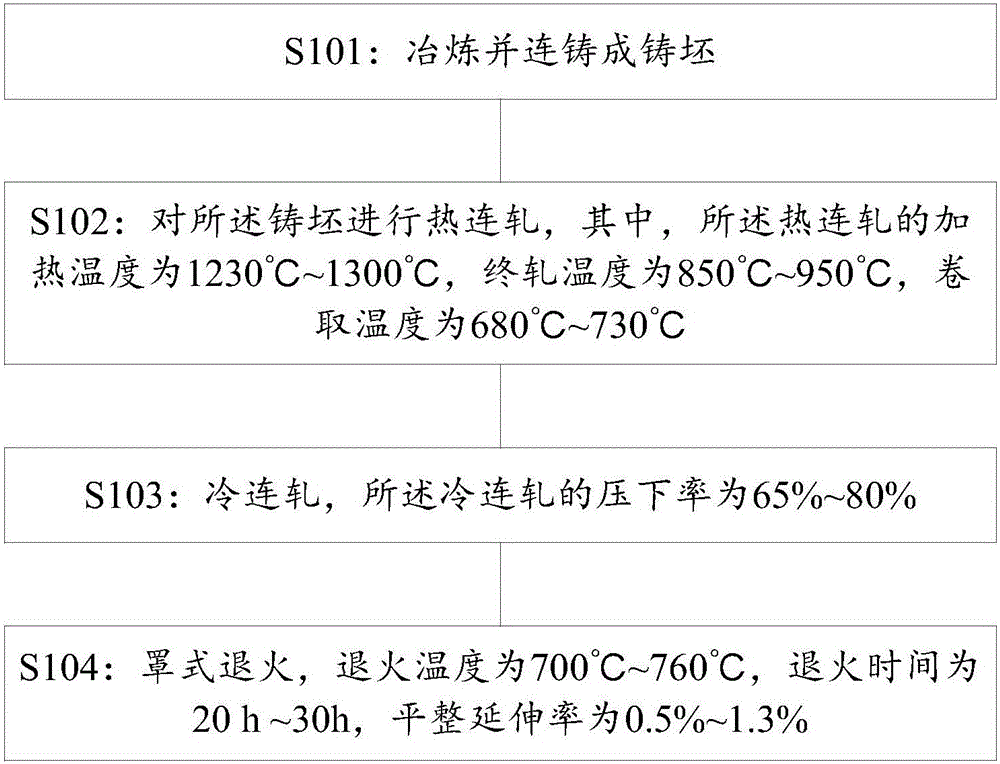

[0044] Based on the same inventive concept, the present application also provides a method for manufacturing a corrosion-resistant enamel heat transfer element steel, the method comprising the following steps:

[0045] Step S101: smelting and continuous casting into slabs, specifically including: molten iron pretreatment, converter smelting, refining and continuous casting;

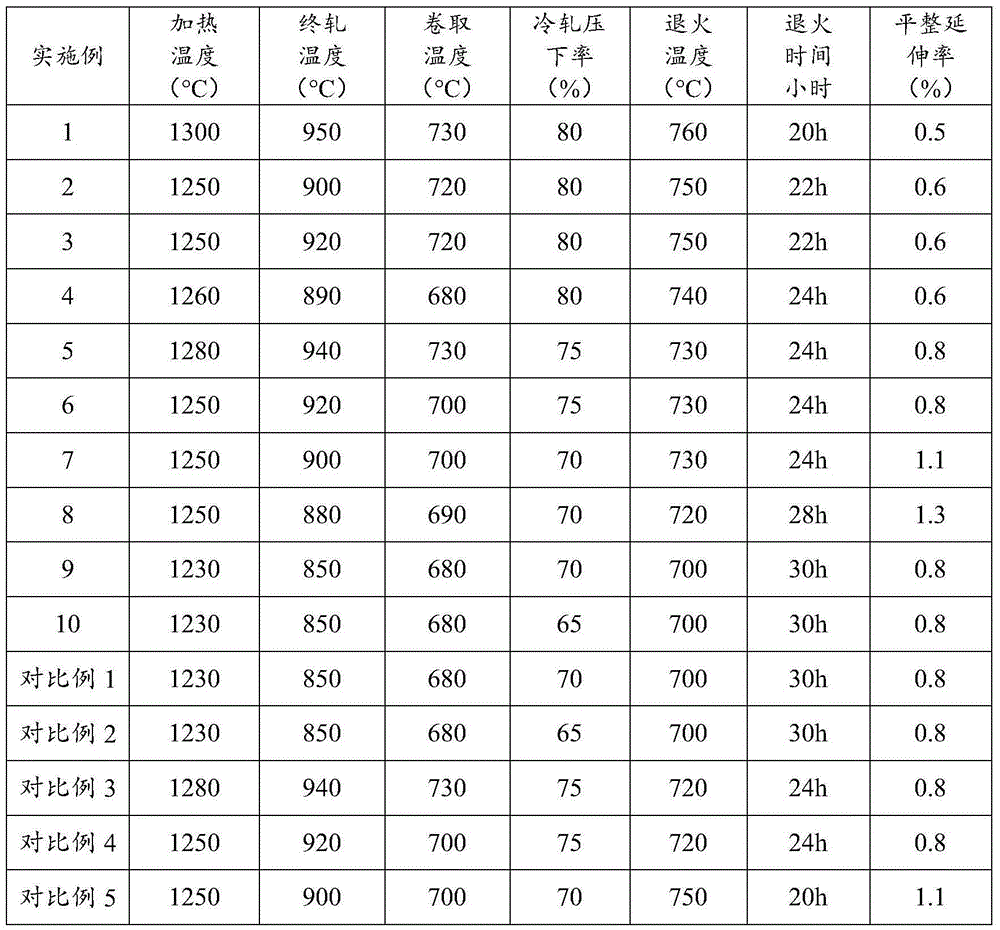

[0046] Step S102: performing continuous hot rolling on the slab, wherein the heating temperature of the continuous hot rolling is 1230°C-1300°C, the finishing temperature is 850°C-950°C, and the coiling temperature is 680°C-730°C;

[0047] Step S103: continuous cold rolling, the reduction rate of the continuous cold rolling is 65%-80%;

[0048] Step S104: bell annealing, the annealing temperature is 700°C-760°C, the annealing time is 20h-30h, and the flat elongation is 0.5%-1.3%.

[0049] Specifically, before step 104, the method further includes pickling.

[0050] Specifically, after step 104, the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com