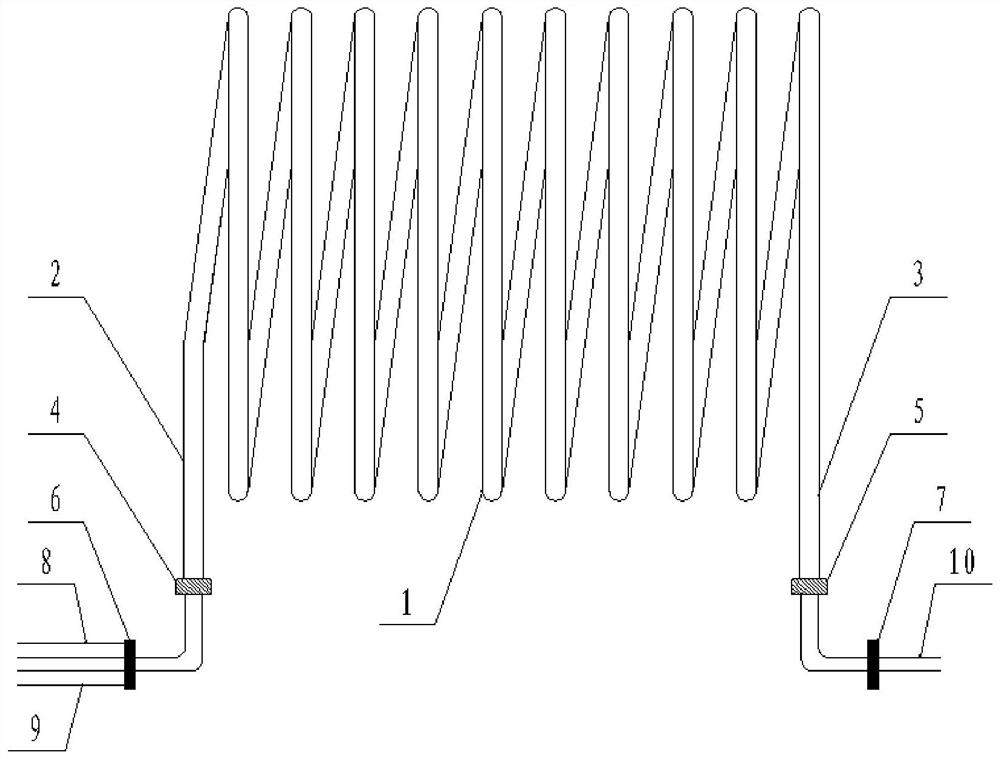

An integrated method for coating and drying solar water tanks

A solar water tank and integrated technology, which is applied in the field of integrated coating and drying of solar water tanks, can solve the problems of affecting the quality and service life of the coil, the complex shape of the coil, and the thinning of the glaze slurry, so as to improve the quality and Work efficiency, improve coating quality, and save usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

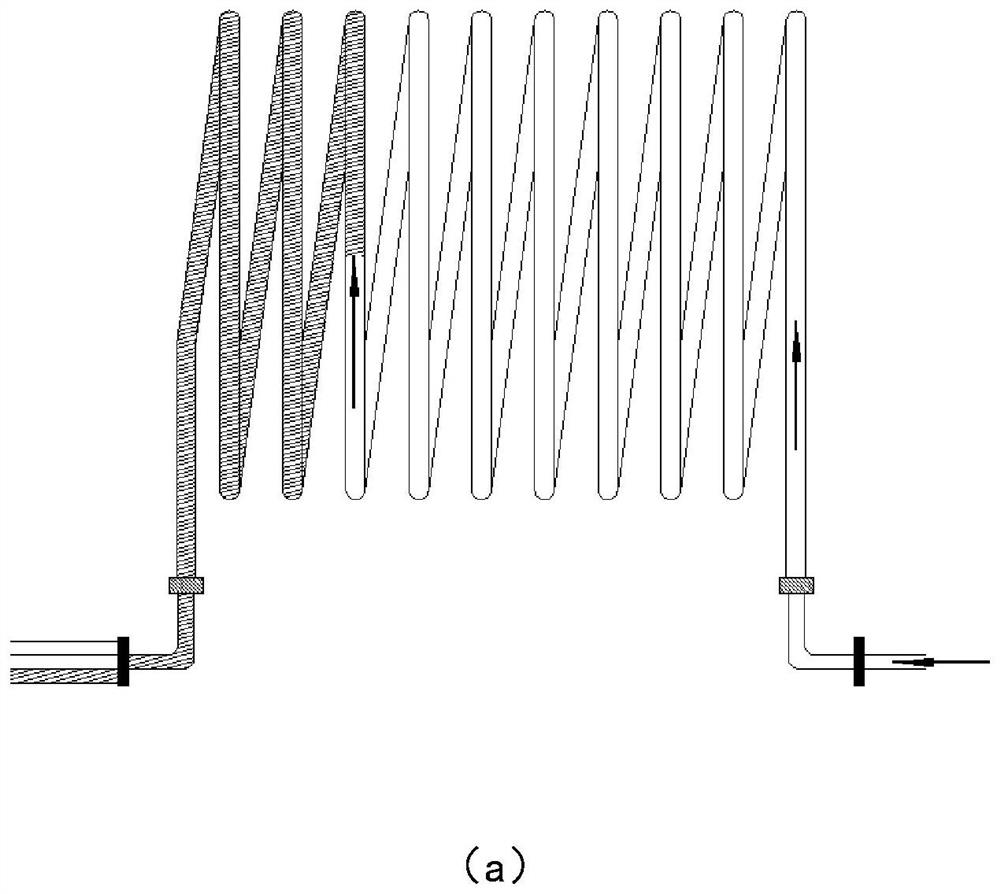

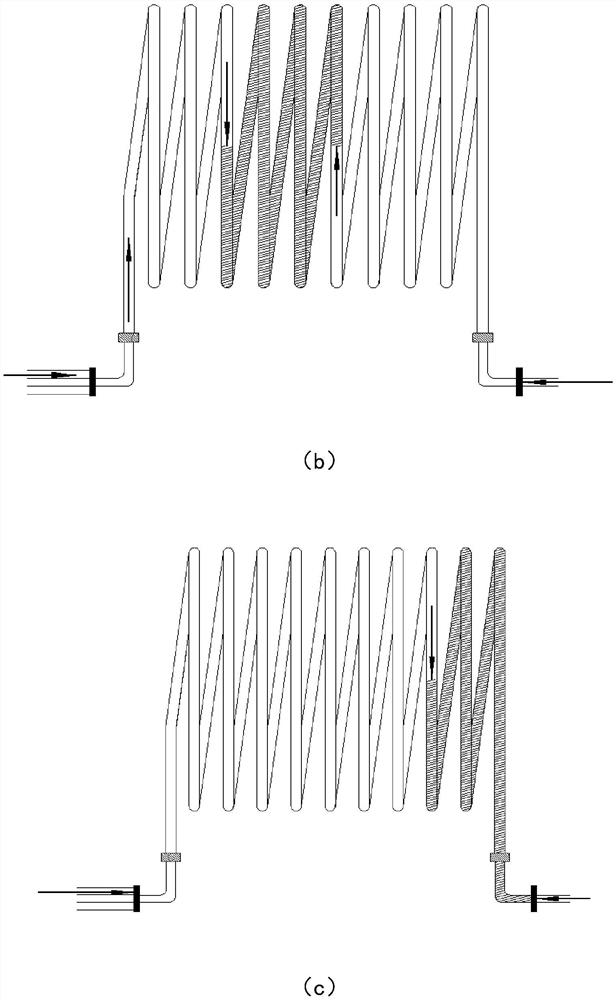

Method used

Image

Examples

Embodiment approach

[0031] In addition, the present invention also includes the following preferred embodiments, including:

[0032] (2) Enameling the inner tank: the inner tank is coated and sintered by conventional methods or other methods;

[0033] (3) Welding and assembly: Weld together the coiled tube and the inner tank after passing the inspection.

[0034] Before the inner wall of the coil is coated with enamel, pickling, flushing, gas purging, etc. can be used to remove sundries and oxide layers on the inner wall.

[0035] In addition, the enamel enamel slurry used in the present invention and the liner enamel coating method also include the following preferred embodiments, including:

[0036] (1) Preparation of glaze paste:

[0037] The raw material components of the glaze slurry used in the present invention at least include: SiO 2 : 52-58 parts by mass, feldspar powder: 48-50 parts by mass, boric anhydride: 18-25 parts by mass, alumina: 4-6 parts by mass, sum of cobalt oxide and nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com