Stereo-positioning effect dry granule complete-polished ceramic brick and preparation method thereof

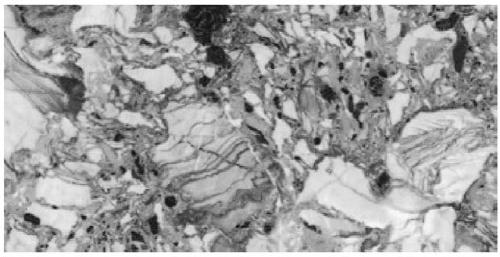

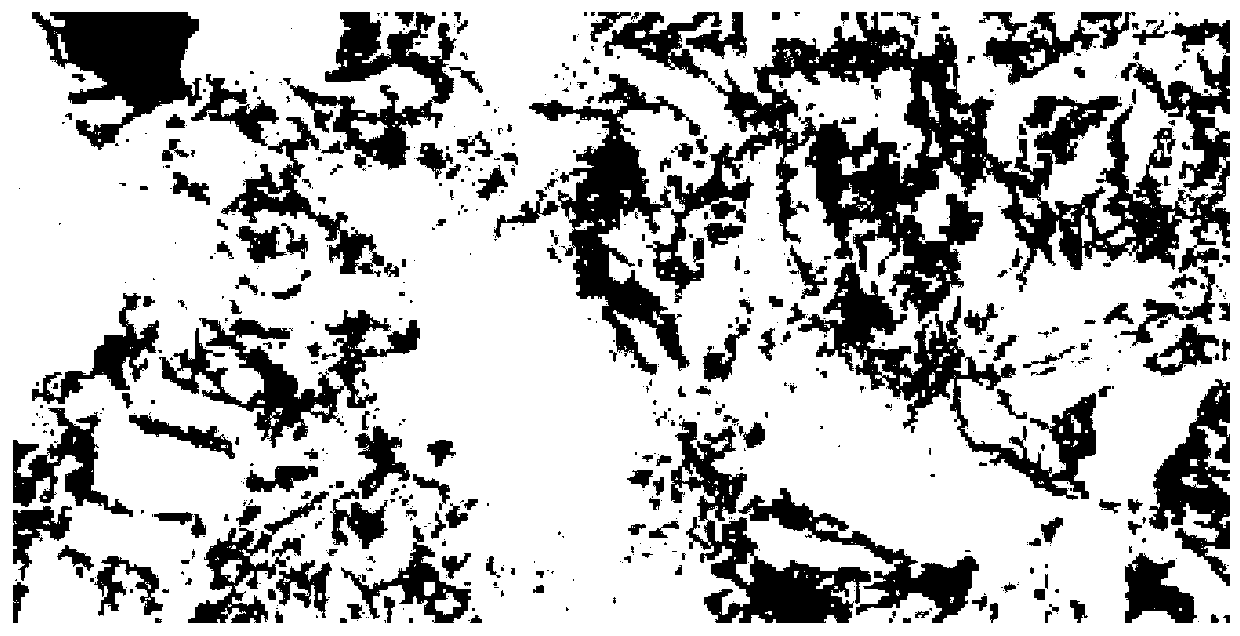

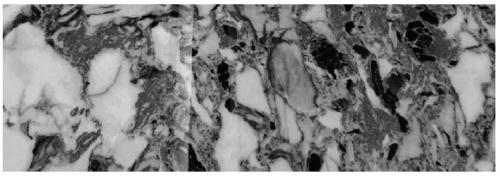

A technology of three-dimensional positioning and ceramic tiles, which is applied in the direction of imitating three-dimensional effect patterns, ceramic molding machines, and patterns characterized by projection effects, etc., which can solve the problems of single decorative effect, combination, inconsistent dry particle amount, etc., and achieve color effect Gorgeous, high mirror flatness, strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1. Pressed adobe with ordinary ceramic base material.

[0065] 2. Kiln drying, the drying time is 1 hour, and the moisture content of the dried billet is controlled within 0.5%.

[0066] 3. Spray surface glaze, chemical composition of surface glaze: loss on ignition: 4.31%, SiO 2 : 50.40%, Al 2 o 3 : 29.41%, Fe 2 o 3 : 0.37%, TiO 2 : 0.07%, CaO: 0.71%, MgO: 0.21%, K 2 O: 5.64%, Na 2 O: 2.57%, P 2 o 5 : 0.21%, ZrO 2 : 6.10%, surface glaze specific gravity 1.44, glaze amount 500g / m 2 .

[0067] 4. Inkjet printing pattern, using a digital inkjet printer (purchased from Flow Company) to print.

[0068] 5. Spray into the protective glaze, the chemical composition of the protective glaze: loss on ignition: 5.31%, SiO 2 : 56.92%, Al 2 o 3 : 17.50%, Fe 2 o 3 : 0.18%, CaO: 6.59%, MgO: 2.11%, K 2 O: 3.45%, Na 2 O: 2.90%, P 2 o 5 : 0.16%, BaO: 1.66%, ZnO: 3.22%, specific gravity 1.21, glaze amount 280g / m 2 .

[0069]6. By processing the design pattern in ink...

Embodiment 2

[0079] The difference from Example 1 is that the yellow dry particles are scattered. The chemical composition of its dry particles: loss on ignition: 3.71%, SiO 2 : 62.90%, Al 2 o 3 : 10.70%, Fe 2 o 3 : 0.22%, BaO: 0.15%, CaO: 8.96%, ZrO 2 : 3.86%, MgO: 1.67%, K 2 O: 2.91%, Na 2 O: 3.54%, ZnO: 0.85%, PbO: 0.13%, MoO 3 : 0.21%, Pr 6 o 11 : 0.19%. The amount of yellow dry grains is 400g / m 2 , The effective dry granular layer thickness is 0.10mm. The particle gradation of yellow dry glaze is: 60-80 mesh: 31%, 80-100 mesh: 22%, 100-120 mesh: 23%, 120-160 mesh: 9%, 160-250 mesh: 15% , Below 250: 0%.

[0080] Distribute transparent dry granule frit, the amount of frit dry granule is 1000g / m 2 , the thickness of the effective dry grain layer is 0.30mm, and the chemical composition of the transparent frit is: loss on ignition: 0.73%, SiO 2 : 60.20%, Al 2 o 3 : 11.50%, Fe 2 o 3 : 0.16%, TiO 2 : 0.43%, CaO: 11.22%, MgO: 0.46%, K 2 O: 6.09%, Na 2 O: 2.83%, ZnO: 6.38...

Embodiment 3

[0084] The difference from Example 1 is that the black dry particles are sprinkled. The chemical composition of its dry particles: loss on ignition: 0.19%, SiO 2 : 45.50%, Al 2 o 3 : 17.00%, Fe 2 o 3 : 0.94%, BaO: 0.14%, CaO: 13.40%, ZrO 2 : 5.43%, MgO: 0.24%, K 2 O: 1.49%, Na 2 O: 3.42%, ZnO: 3.41%, PbO: 0.13%, MoO 3 : 0.19%, CoO: 1.52%, TiO 2 : 0.17%, Cr 2 o 3 : 0.17%, Sr: 0.15%, HfO 2 : 0.36%, MnO: 6.15%. Green dry grain amount 400g / m 2 , The effective dry granular layer thickness is 0.10mm. The particle gradation of black dry glaze is: 60-80 mesh: 32%, 80-100 mesh: 21%, 100-120 mesh: 22%, 120-160 mesh: 9%, 160-250 mesh: 16% , Below 250: 0%.

[0085] Distribute transparent dry granule frit, the amount of frit dry granule is 1200g / m 2 , the thickness of the effective dry grain layer is 0.40mm, and the chemical composition of the transparent frit is: loss on ignition: 0.98%, SiO 2 : 60.66%, Al 2 o 3 : 11.50%, Fe 2 o 3 : 0.26%, TiO 2 : 0.48%, CaO: 9.36%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com