Method and system for scribing brittle ultrathin piece by water jet and laser

A technology for laser scribing and brittle materials, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of expensive micro-jet laser equipment, difficult to obtain production materials, and high equipment maintenance costs, and achieve optimal planning. Improve chip surface quality, improve scribing yield, eliminate residual stress and micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

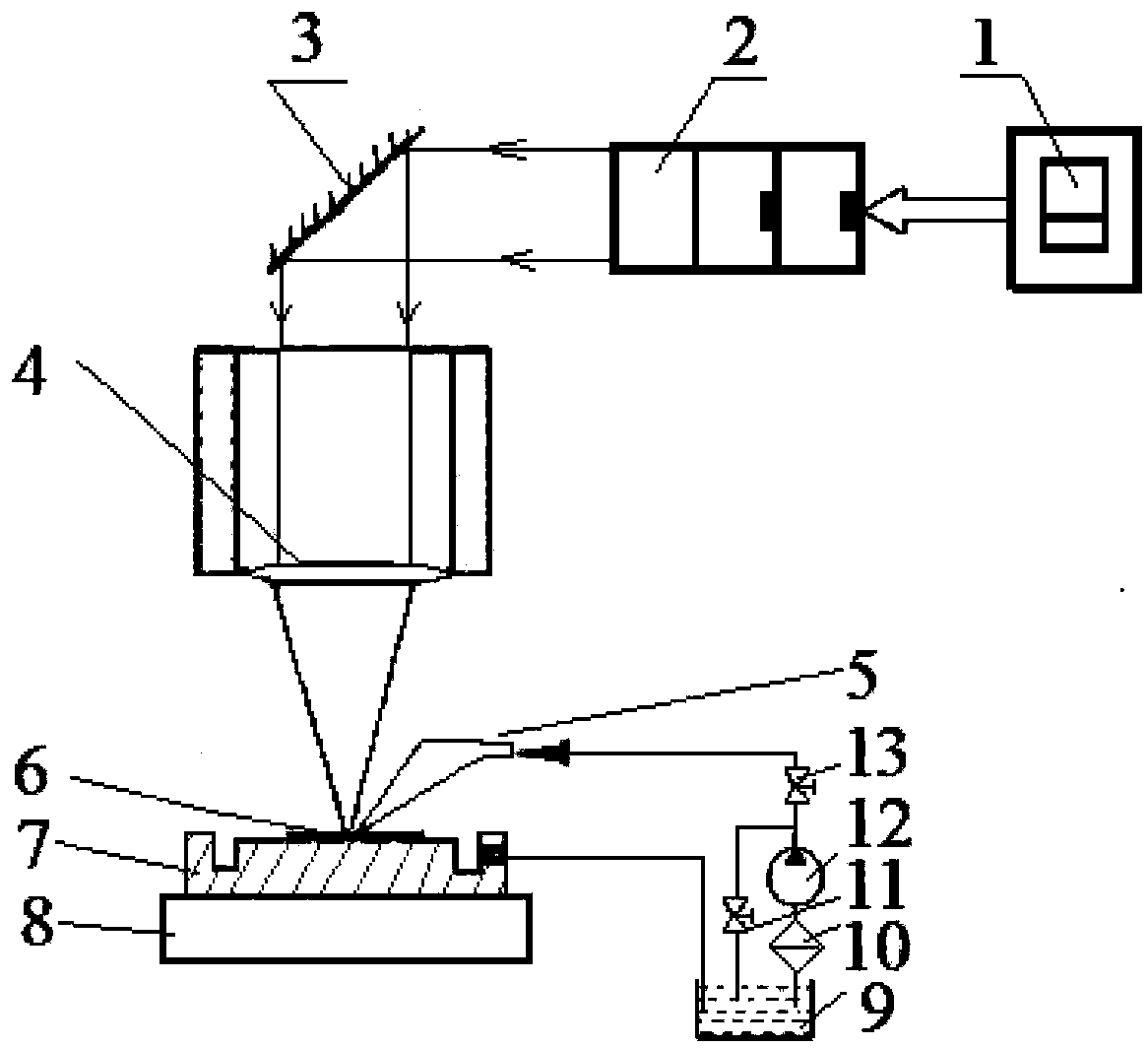

[0031] The structure of Example 1 of the system for marking ultra-thin sheets of brittle materials by water jet laser is as follows figure 1 As shown, it includes a laser control unit, a pulse laser, a focusing lens and a jet nozzle. The laser control unit 1 is connected to and controls the pulse laser 2. The laser beam emitted by the pulse laser 2 is changed in direction by the mirror 3 and then focused on the workpiece by the focus lens 4. 6 surfaces. There is a working chamber 7 equipped with water above the workbench 8. The workbench 8 has a boss located in the workchamber 7. The workpiece 6 is fixed on the boss of the workbench 8. The surface of the workpiece 6 on the boss of the workbench 8 is lower than the work chamber. 7. The surface of the inner water is 0.5-1.5mm, that is, there is a water layer of 0.5-1.5mm on the surface of the workpiece 6. The working cavity 7 has an overflow port, and the lowest point of the overflow port is 0.5-1.5 mm higher than the surface o...

Embodiment 2

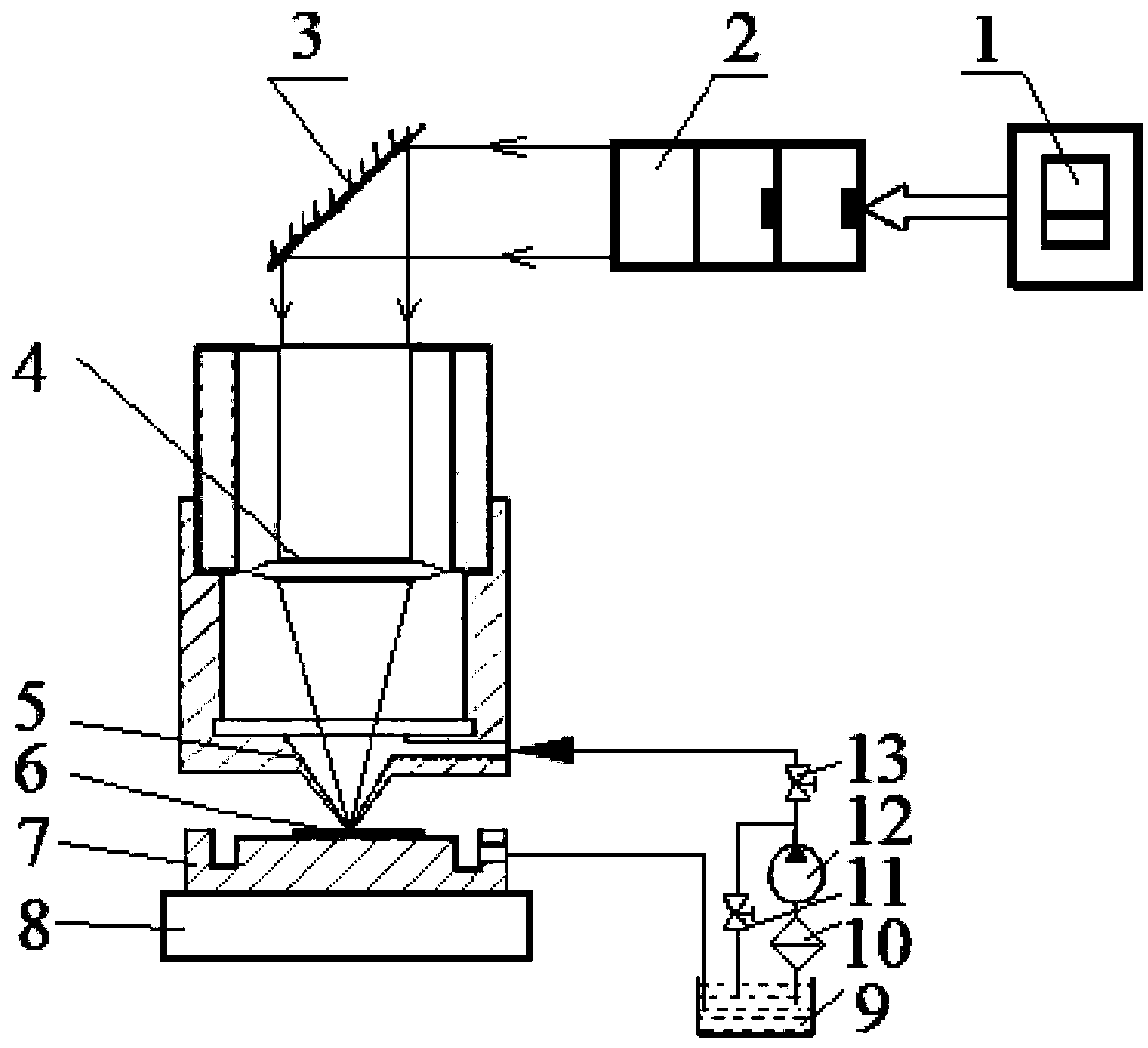

[0038] The structure of Example 2 of the system for marking ultra-thin sheets of brittle materials by water jet laser is as follows figure 2 As shown, the longitudinal centerline of the jet nozzle 5 of this example coincides with the centerline of the laser beam, and the laser beam passes through the focusing lens 4, passes through the nozzle hole of the jet nozzle 5, and then passes through the water jet to focus on the surface of the workpiece 6. The center of the focal point on the surface of 6 coincides with the center of the injection point of the water jet beam on the surface of the workpiece 6 . Cooling and flushing are better accomplished with water jets.

[0039] The jet nozzle 5 orifice diameter of this example is 3mm.

[0040] The water of this example water jet is distilled water.

[0041] The water jet laser engraving method for brittle material ultra-thin sheets in this example is that the center line of the water jet beam coincides with the center line of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com