Forming mold for semi-spherical components and multi-pass forming method

A forming mold and hemispherical technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult control of deep drawing process parameters, difficult to guarantee shape accuracy, poor product surface quality, etc., and achieve breakthrough forming technology. Bottleneck, save processing cost, eliminate the effect of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

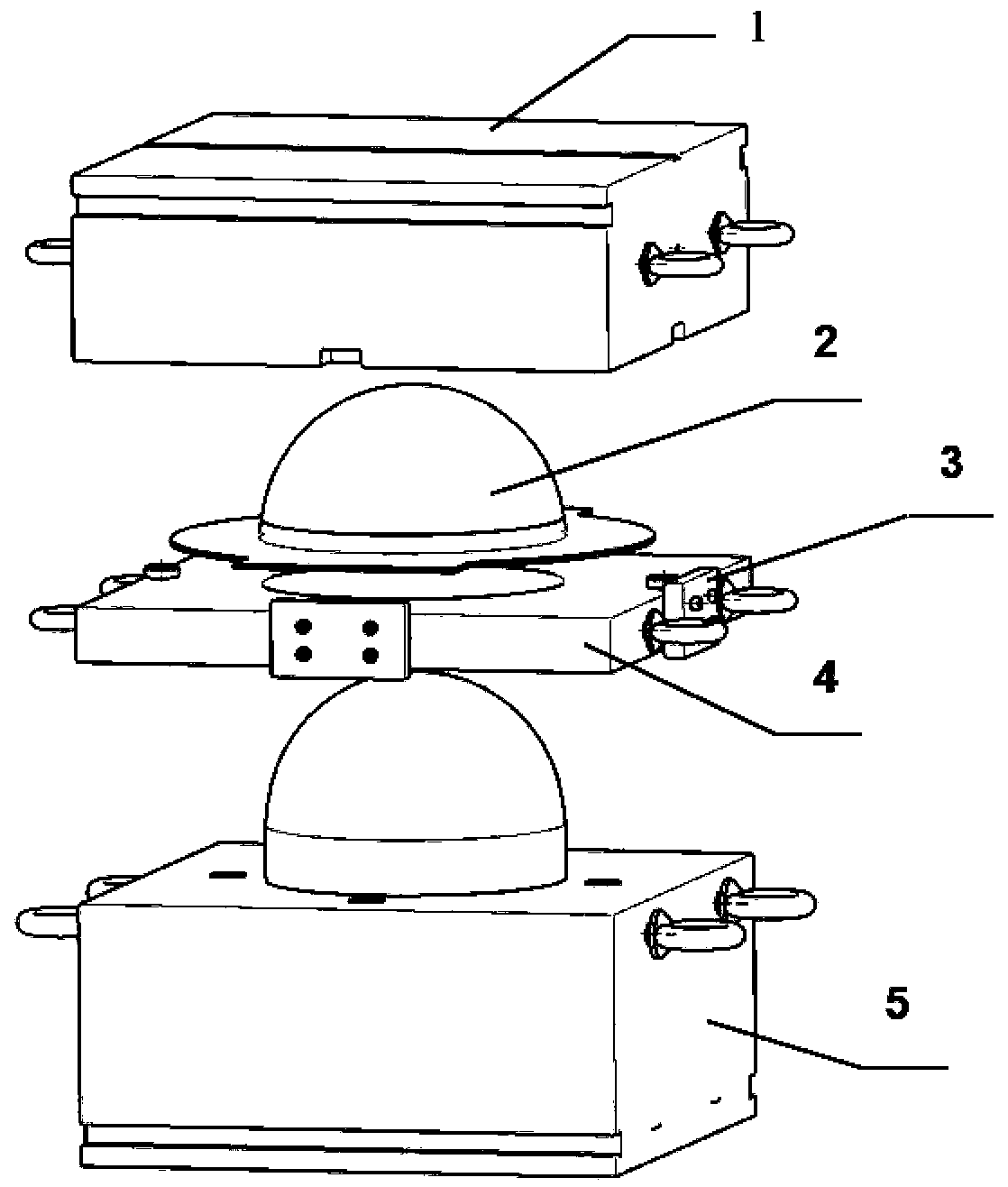

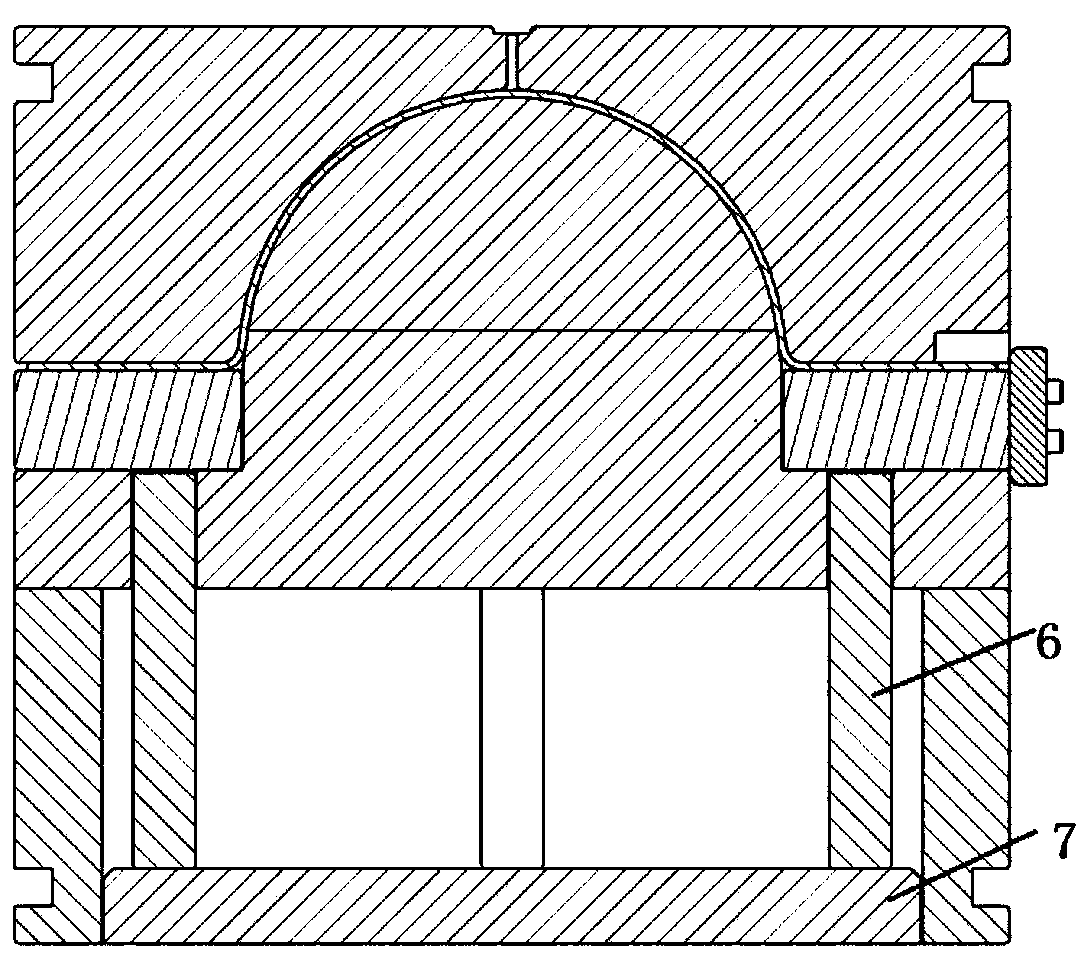

[0053] This embodiment provides a forming die for a hemispherical member, such as Figure 1-Figure 2 As shown, it includes a die 1, a punch 5, a blank holder 4 and a positioning plate 3; the die 1 and the punch 5 are used to form a hemispherical member; , the blank holder 4 cooperates with the die 1 to compress the blank 2, which is used to prevent the blank 2 from being unstable and wrinkled during the forming process; the two adjacent sides of the blank holder 4 are respectively provided with a positioning plate 3, and the positioning plate 3 is used for positioning the upper mold and the lower mold. The positioning plate 3 is screwed to the side of the blank holder 4 and the positioning plate 3 is vertically distributed.

[0054] It also includes an adapter plate 7 for increasing the ejection radius; the lower platform of the forming machine includes the lower jack cylinder and the first ejector rod, but the ejection radius formed by the first ejector rod is small, and the...

Embodiment 2

[0083] Take the 5083 aluminum alloy hemispherical member as an example, its dimensions are shown in figure 1 , the component thickness is 4mm, the aspect ratio is 1.2:1, and the total height is 260mm.

[0084] The specific forming process is carried out as follows:

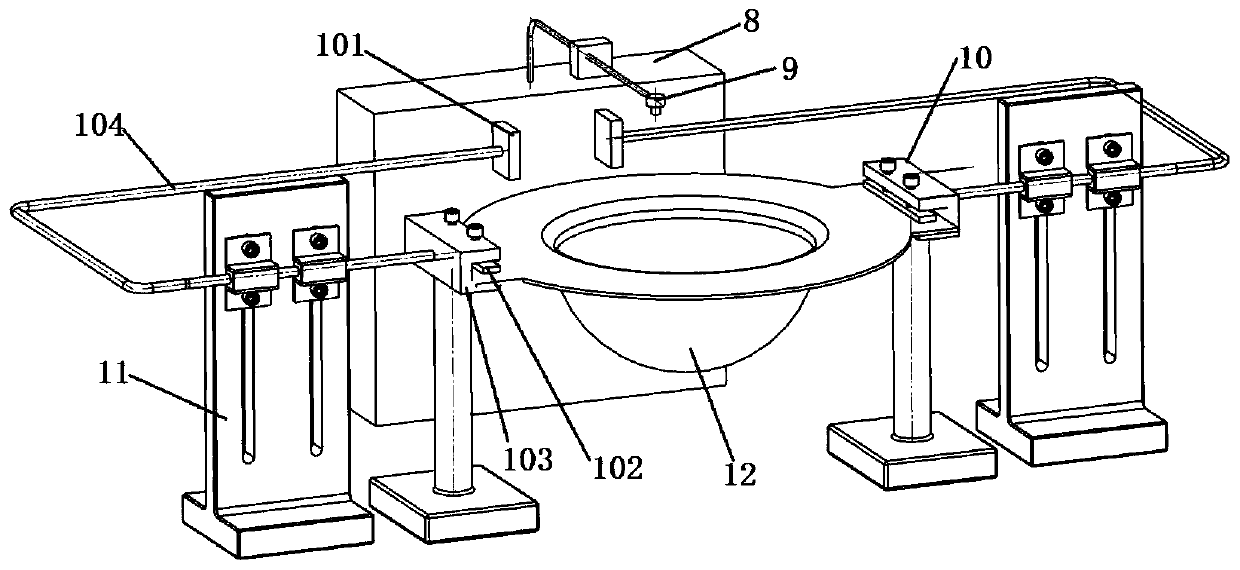

[0085] Step (1) Determine the size of the blank 2: select the 4mm thick 5083 aluminum alloy raw material plate required for forming, and supplement the margin and process flange edge according to the characteristics of the component, such as figure 2 shown. Using FormingSuite software for numerical simulation, the number of grids is 6900, the material strain hardening index is 0.25, Young's modulus is 70GPa, Poisson's ratio is 0.33, blank holder force is 5t, and drawing force is 200t. Simulate and expand to determine the blanking size as 4×Φ850mm. When blanking, two lugs are added to the relative positions of the blank 2 to facilitate the clamping of the blank 2 when the strong pulse current assists in tissue ...

Embodiment 3

[0093] Taking TA2 pure titanium hemispherical component as an example, its dimensions are shown in figure 1 , the component thickness is 6mm, the aspect ratio is 1.3:1, and the total height is 310mm.

[0094] The specific forming process is carried out as follows:

[0095] Step (1) Determine the size of the blank 2: select the 6mm thick TA2 pure titanium raw material plate required for forming, and supplement the margin and process flange edge according to the characteristics of the component (such as figure 2shown). Using FormingSuite software for numerical simulation, the number of grids is 7800, the material strain hardening index is 0.13, Young's modulus is 103GPa, Poisson's ratio is 0.35, blank holder force is 20t, and drawing force is 400t. Simulate and expand to determine the blanking size as 6×Φ940mm. When blanking, two lugs are added to the relative positions of the blank 2 to facilitate the clamping of the blank 2 when the strong pulse current assists in tissue r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com