Laser machining method and system of surface composite micro-structure of nodular cast iron material

A nodular cast iron and surface composite technology, which is applied in laser welding equipment, metal processing equipment, cleaning methods and appliances, etc., can solve the problems of the development limitation of composite micro-textured surface technology, the inability to prepare multiple sizes, and low processing efficiency. , to achieve the effect of eliminating original scratches and microcracks, low cost, and eliminating microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

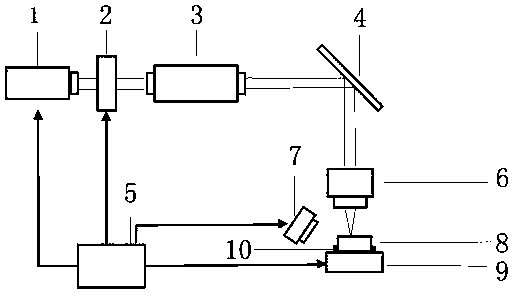

[0016] refer to figure 1 : Laser processing system for composite micro-texture on the surface of ductile iron materials, which is a processing system with focusing lens, including laser [1], photoelectric shutter [2], beam expander [3], mirror [4], computer control system [5], focusing lens [6], CCD [7], workpiece [8], stage [9] and fixture [10]. The computer control system [5] is connected to the laser [1], photoelectric shutter [2], CCD [7] and displacement stage [9] through lines respectively.

[0017] The method for processing the composite microtexture on the surface of a ductile iron material by laser comprises the following steps.

[0018] (1) Prepare the workpiece [8], the workpiece material is QT900-5, firstly polish the surface with sandpaper to make the surface burr-free and smooth. Ultrasonic cleaning with acetone, ethanol, and water for 1-3 minutes each to make the surface free of oil, particles, and other pollution.

[0019] (2) Fix the fixture [10] on the di...

Embodiment 2

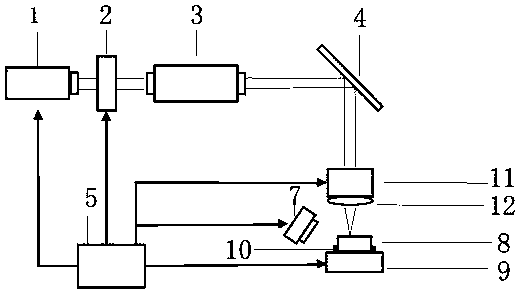

[0023] refer to figure 2 : Laser processing system for composite micro-texture on the surface of ductile iron materials, which is a processing system with focusing lens, including laser [1], photoelectric shutter [2], beam expander [3], mirror [4], computer control system [5], CCD[7], workpiece[8], displacement stage[9], scanning galvanometer[11] and f-θ mirror[12]. The computer control system [5] is connected to the laser [1], photoelectric shutter [2], CCD [7], displacement stage [9] and scanning galvanometer [11] respectively through lines.

[0024] The method for processing the composite microtexture on the surface of a ductile iron material by laser comprises the following steps.

[0025] (1) Prepare the workpiece [8]. The material of the workpiece [8] is QT900-5. First, polish the surface with sandpaper to make the surface burr-free and smooth. Ultrasonic cleaning with acetone, ethanol, and water for 1-3 minutes each to make the surface free of oil, particles, and oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com