NbN-Ag hard thin film and preparation method thereof

A kind of thin film and hard technology, which is applied in the field of NbN-Ag hard structure thin film and preparation, coating and its preparation, can solve the problems of poor friction and wear performance of multilayer film at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation of NbN-Ag thin film was completed on JGP-450 high vacuum multi-target magnetron sputtering equipment. The magnetron sputtering apparatus has three sputtering targets, which are respectively installed on three water-cooled brackets, and three stainless steel baffles are respectively installed in front of the three targets, and are automatically controlled by a computer.

[0021] A pure Nb target (99.9%) and a pure Ag target (99.95%) are used as double targets, respectively installed on independent radio frequency cathodes, and the target diameter is 75mm. The surface of hard alloy or ceramic substrate such as high-speed steel is mirror-polished, and the vacuum chamber is filled with Ar and N with a purity of 99.999%. 2 The mixed gas is used to deposit a NbN-Ag hard structure film by using a pure Nb target and a pure Ag target on a hard alloy or ceramic substrate to perform double-target confocal radio frequency reactive sputtering. Before depositing the ...

specific Embodiment

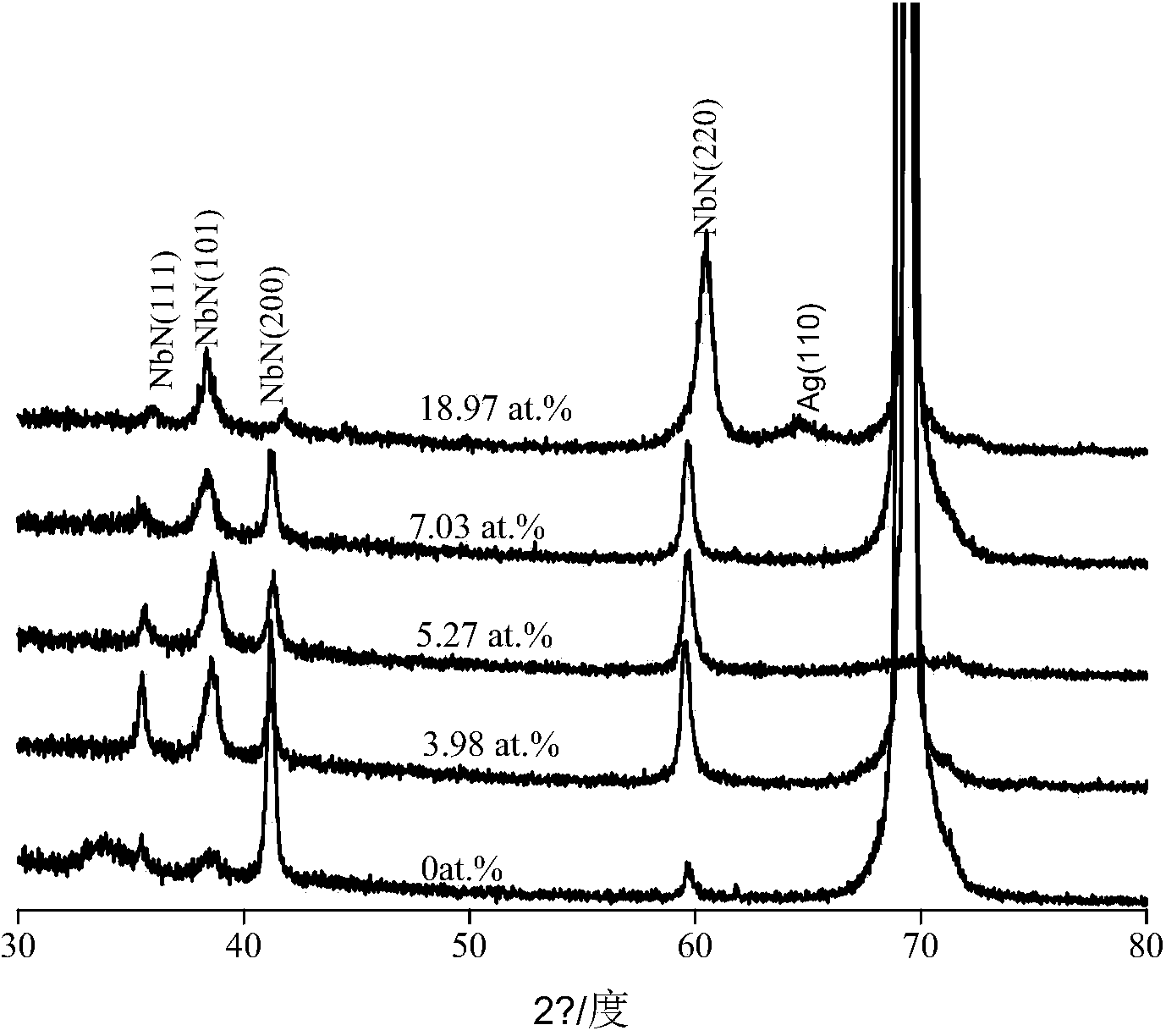

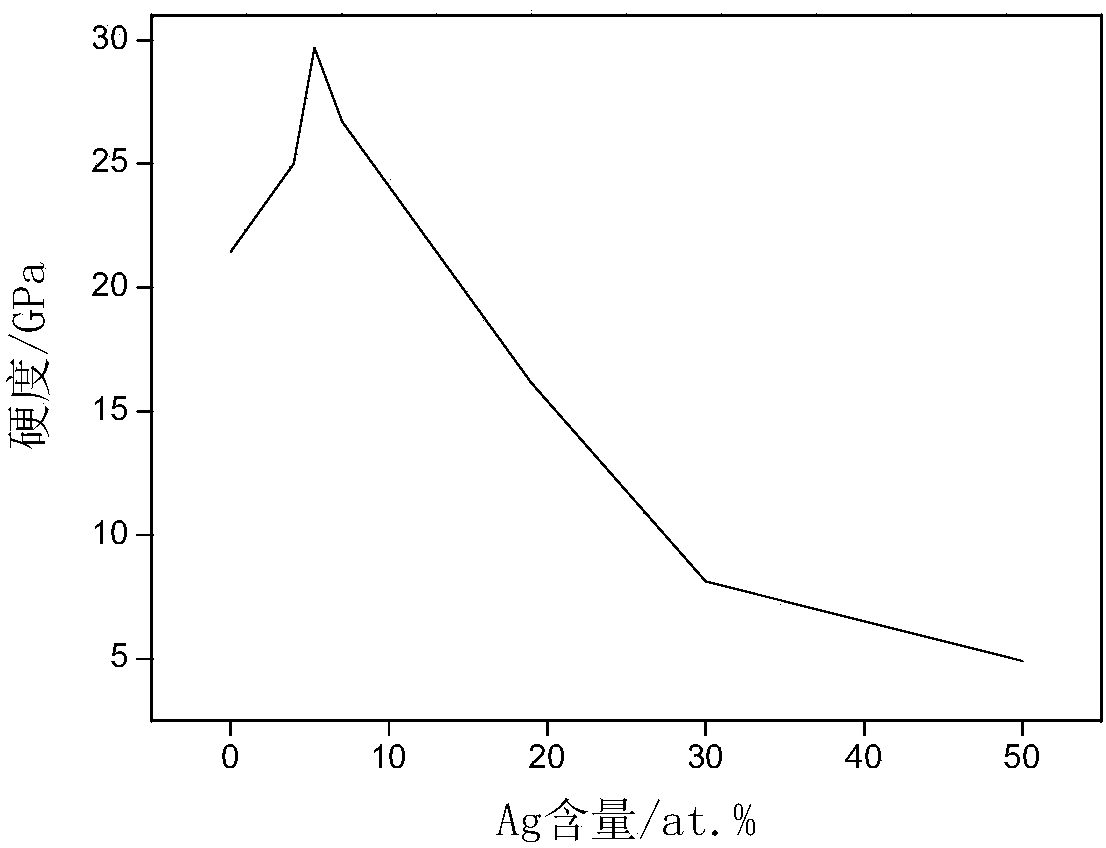

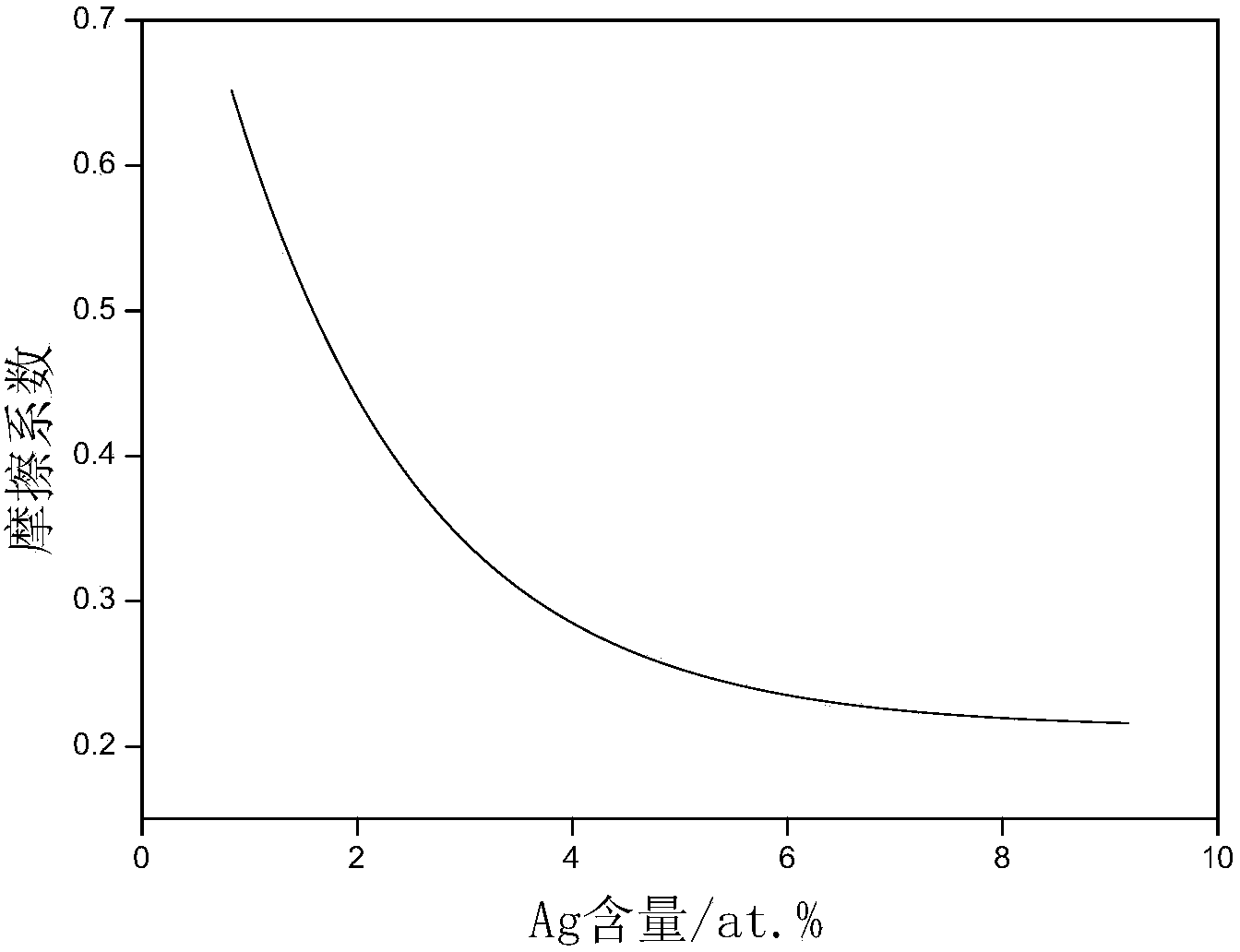

[0024] Embodiment 1-7 shown in table 1 has investigated the influence of different Ag contents on gained thin film film hardness and friction coefficient at normal temperature, and corresponding accompanying drawing sees figure 2 , 3 , 4, it can be seen that the Ag content is 5.27at.%, that is, the hardness is the highest when the Ag target is 20W and the Nb target is 200W.

[0025] Table 1

[0026]

[0027] The embodiment 8-10 shown in table 2 is that the Ag content is 5.27at.% NbN-Ag thin film carries out the investigation result of friction experiment, relevant accompanying drawing sees Figure 5 .

[0028] Table 2

[0029]

[0030] The above examples 1-10 only cite the situation where the Nb target power is fixed at 200W, and the argon-nitrogen flow ratio is 10:5. In actual operation, the operable power is Nb target power of 100-500W, and the sputtering pressure of the deposition process is 0.3 Pa, argon nitrogen flow ratio 10: (1 ~ 10).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com