Metal 3D printer based on interlayer shock processing process and printing method thereof

A 3D printer and impact strengthening technology, applied in the field of impact strengthening, can solve problems such as porosity and holes, and achieve the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

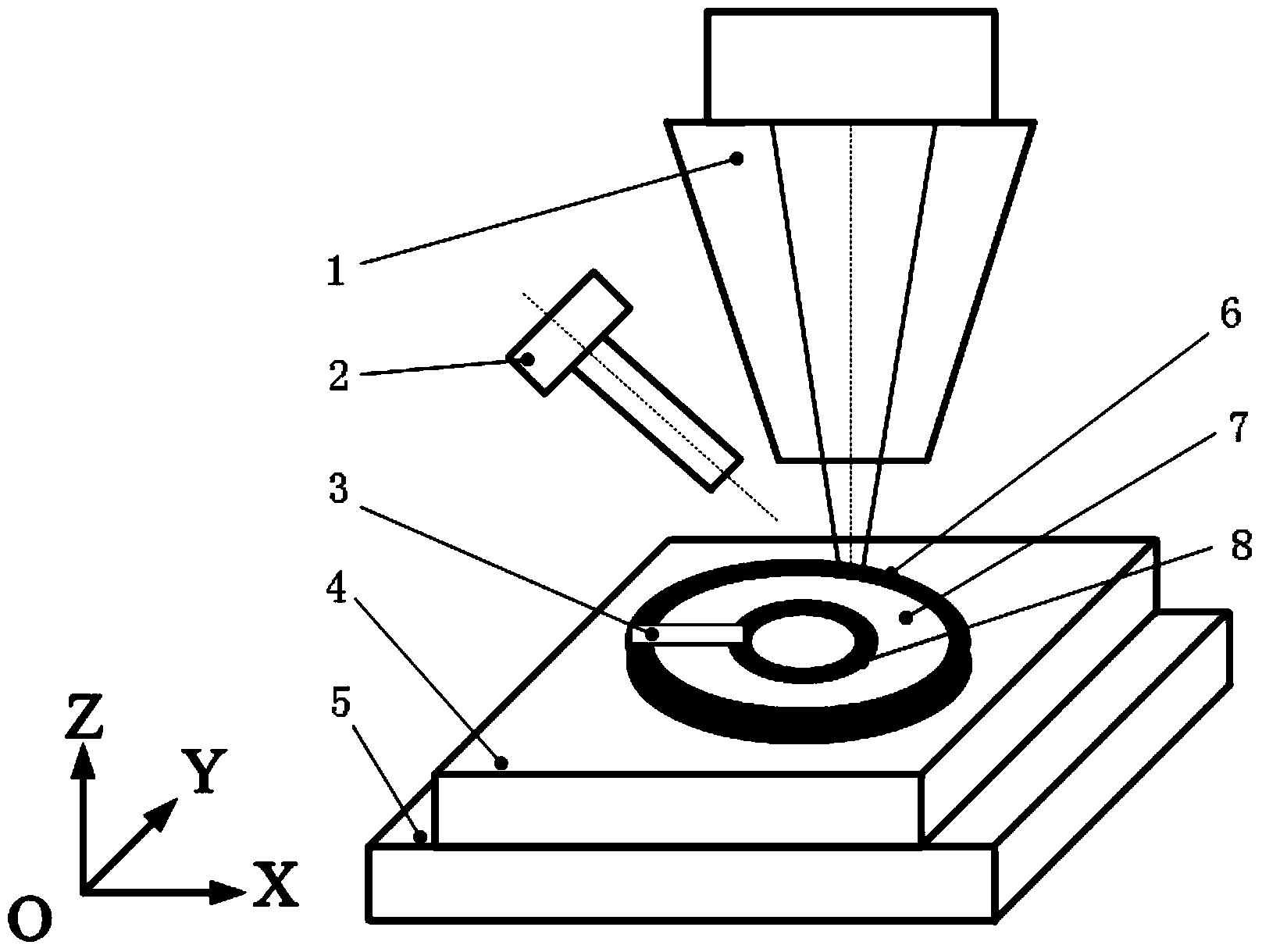

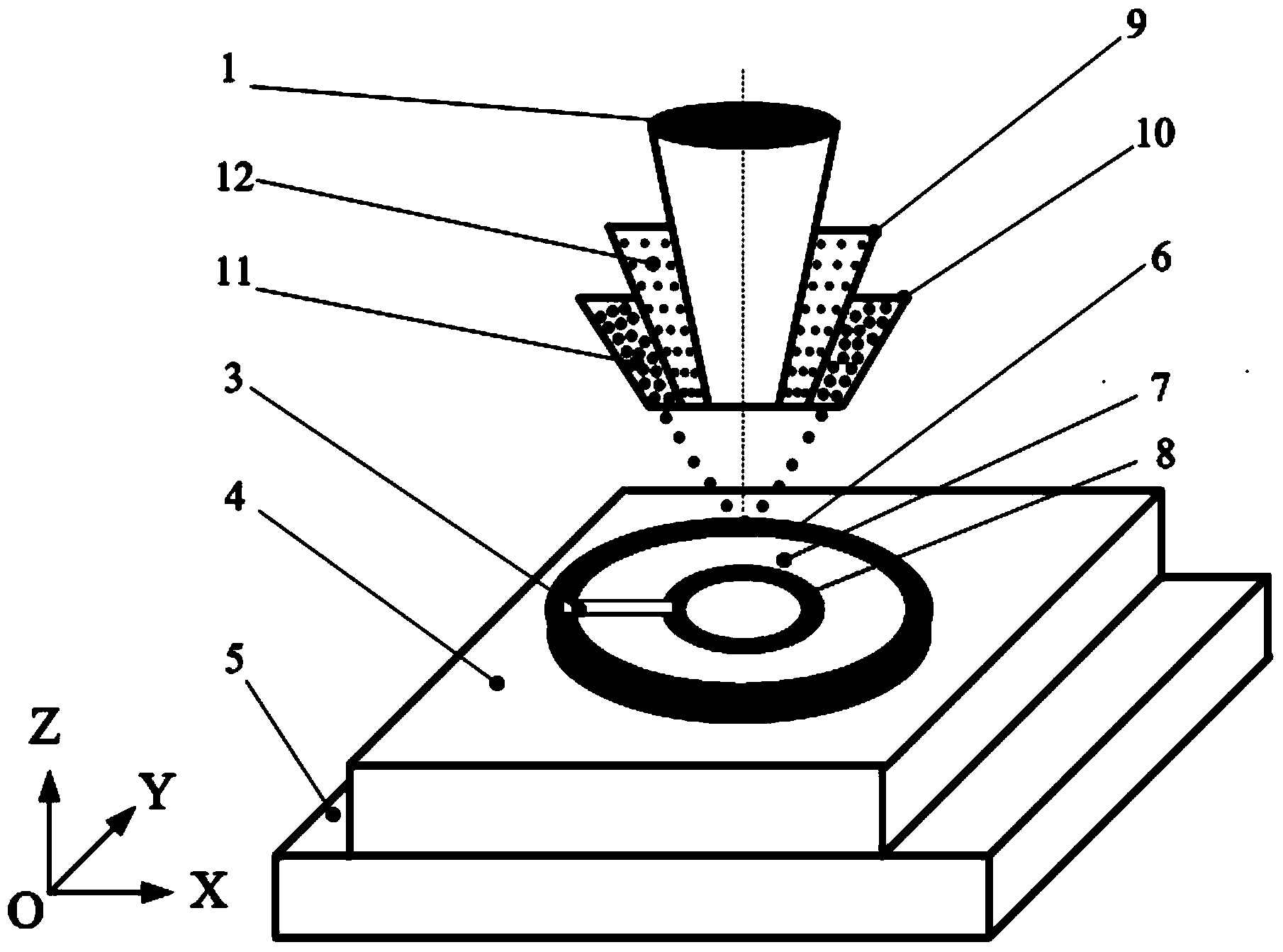

[0029] Such as figure 1 As shown, the metal 3D printer based on the interlayer impact strengthening process of the present invention includes a cladding nozzle 9, a strengthening nozzle 10, and a laser focusing head integrated with the cladding nozzle. The strengthening nozzle 10 performs impact strengthening on the cladding layer 3 formed by the cladding nozzle 9. The strengthening nozzle is a laser shock strengthening nozzle and / or a mechanical shot peening strengthening nozzle, and the angle range between the center line of the strengthening nozzle and the cladding layer is 30°- 60°.

[0030] There are five kinds of mutual cooperation structures between the strengthening nozzle and the cladding nozzle in the present invention: the first one is that the cladding nozzle is arranged in the center, and the strengthening nozzle is arranged on the periphery of the cladding nozzle, and the strengthening nozzle includes 3-5 nozzles , each nozzle can be controlled by the electrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com