Chemical mechanical machining and surface finishing

A technology of surface finishing and chemical substances, applied in the direction of mechanical equipment, metal processing equipment, grinding machine tools, etc., can solve problems such as lubricant residue and wear, and achieve the effect of improving machining accuracy and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Example 1 - In-situ surface finishing

[0030] Two similar SAE 4140 carbon steels with nominal dimensions of 3.5 x 1 x 1 / 2 inches and a hardness of 43-45 HRC were used as test specimens. In the past, 3 x 1 / 2 inches of each specimen was mechanically polished in the machine direction with 180 grit wet / dry emery paper. Initial R of Sample 1 a and R max 10.0 microinches and 98.4 microinches, respectively. Initial R of Sample 2 a and R max 17.6 microinches and 167 microinches, respectively.

[0031] Specimen 2 was placed in a solution of 60 g / L oxalic acid and 20 g / L sodium m-nitrobenzenesulfonate with its traditionally mechanically polished side facing up. Then, the conventionally mechanically polished surface of Sample 1 was placed in vertical contact with the conventionally mechanically polished surface of Sample 2 . Specimen 2 was held in a fixed position while specimen 1 was moved back and forth by hand in a circular motion to simulate sliding of critical contact...

example 3

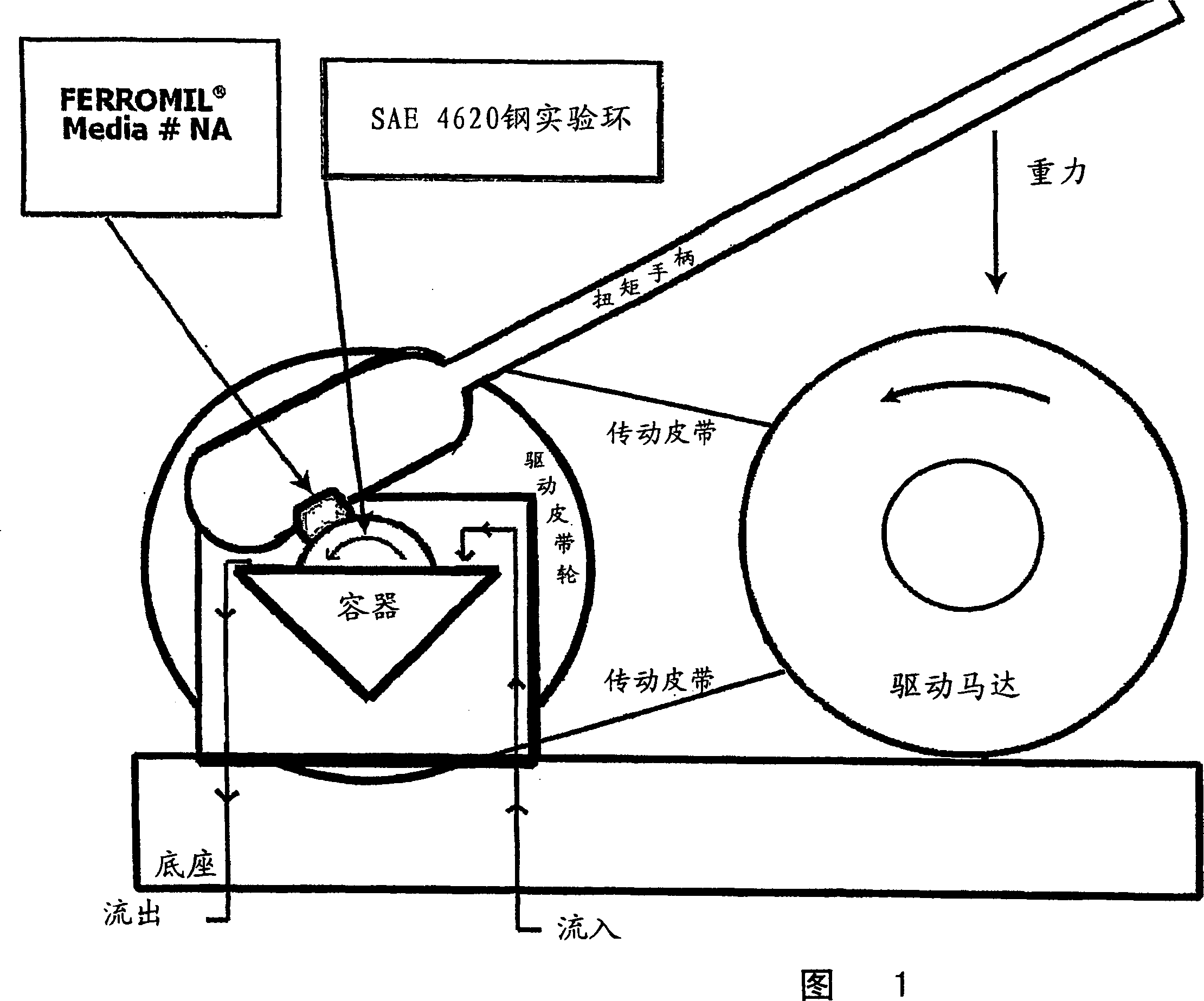

[0041] Example 3 - Chemical Mechanical Processing with Slightly Abrasive Tools

[0042] Slightly abrasive (600 grit) wet / dry emery paper and FERROMIL maintained at 6.25% by volume as the active chemical used to create the conversion coating , a Falex Corporation FLC lubricating test ring with steel grade SAE52100 and hardness HRC57-63 (part #001-502-001P) was machined in a conventional manner.

[0043] A hard plastic mold (Facsimile ) with a 600 grit wet / dry emery paper pressed against it, the Falex Corporation FLC Lubricity Tester rotates the ring at a set speed. The 0-150 foot-pound Sears Craftsman torque handles on which gravity is applied by Falex are the only loads used in the chemical-mechanical method. The ring is partially submerged in 6.5 mL / min of FERROMIL flowing through the container at room temperature FML-575.

[0044] See Figure 1 for a diagram of the experimental setup.

[0045] The test rings were cleaned, dried and weighed on an analytical balance ...

example 5

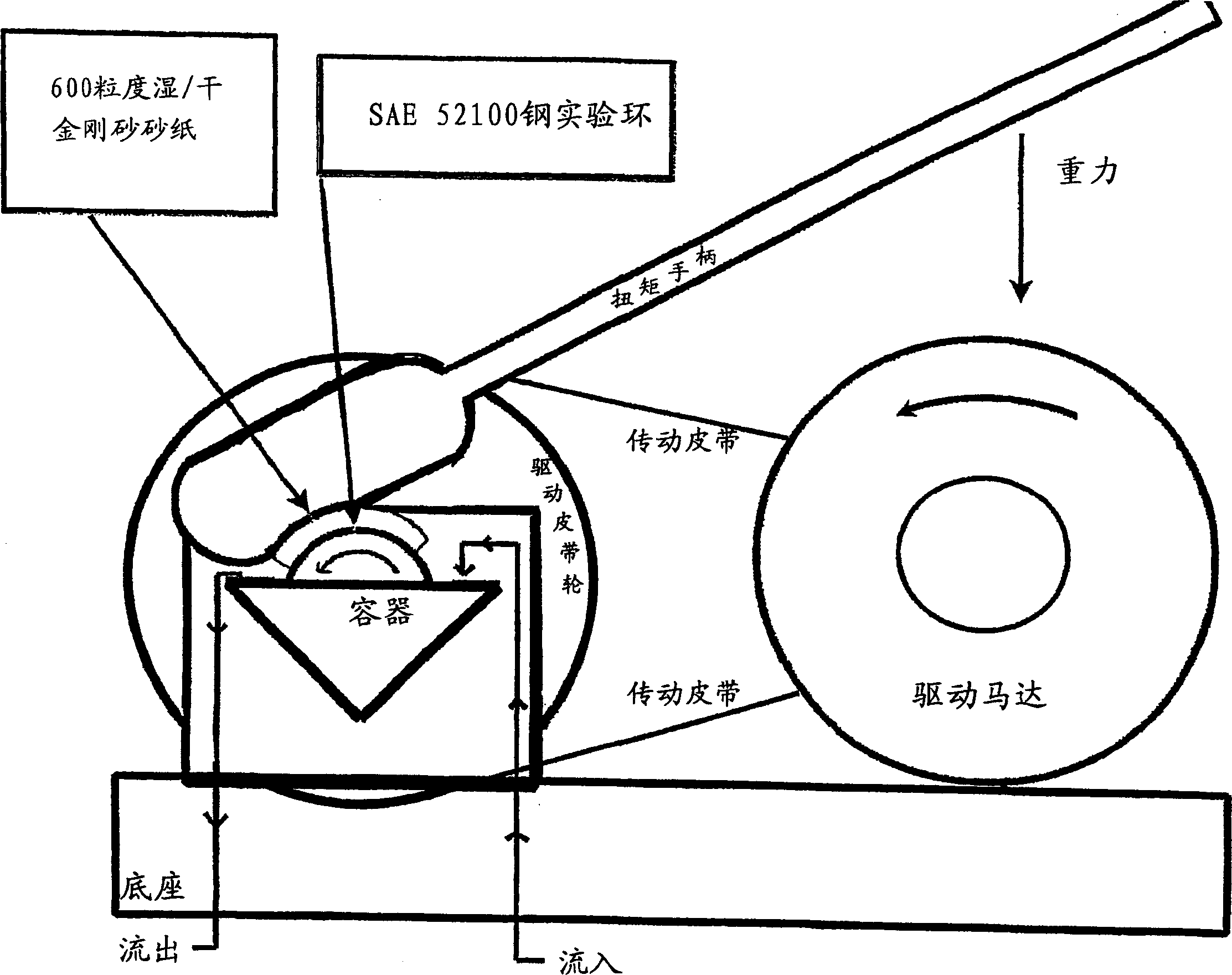

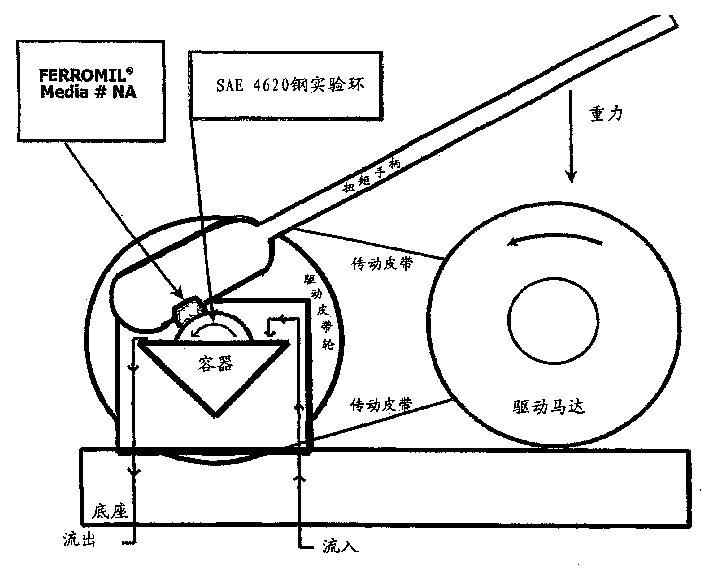

[0056] Example 5 - Chemical mechanical processing with and without abrasive plastic tools

[0057] Use Ferromil VII Aero-700 to finish a FalexCorporation FLC lubrication test ring with steel grade SAE4620.

[0058] In a fixed FERROMIL A Falex Corporation FLC Lubricity Tester rotates the ring at a set speed while Media #NA (plain plastic (polyester resin) without any abrasive particles) contacts the outer ring. The plastic media is shaped as a ring to provide proper surface contact. The ring is partially submerged in 12.5% by volume of FERROM flowing through the container at 6.5 ml / min VIIAero-700. see figure 2 Diagram of the experimental setup.

[0059] The test rings were cleaned, dried and weighed on an analytical balance before and after processing to determine the amount of metal removed.

[0060] The experimental ring weighed 22.1059 grams before processing. Weighed 22.0808 grams after 3 hours of processing at 460 RPM. The total loss was 0.0251 grams or 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com