Method for rolling small-coarseness high-light thin wolfram sheet

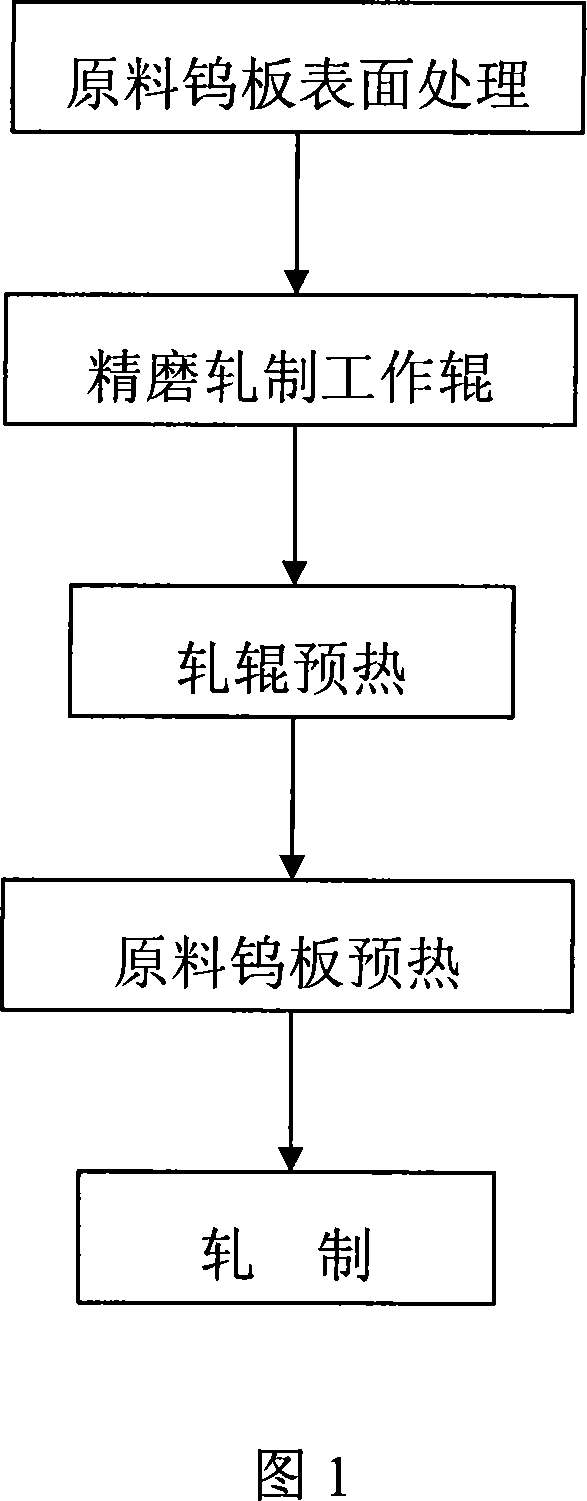

A roughness and high-brightness technology, applied in metal rolling, temperature control, metal rolling, etc., can solve problems such as poor surface consistency and inability to reduce the roughness of tungsten sheets, so as to avoid cracks and peeling, eliminate Surface contamination and microcracks, effect of removing surface contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take a raw tungsten plate with a thickness of 0.2mm, use 240# water sandpaper to grind the surface of the raw tungsten plate, and then use 1%NaOH+4%K 2 CO 3 +4% KCLO 3 + Yu H 2 O electrolyte, polishing for 20min; using fine grinding and rolling work rolls with roughness less than 0.1μm; preheating temperature of rolls is 100℃; preheating temperature of raw tungsten plate is 100℃; The preheated four-high reversing rolling mill directly conducts block rolling without coating graphite and other lubricating materials. The initial rolling force is 40T, and then the rolling force is gradually increased, and the final rolling force is 80T. After multiple passes A thin tungsten sheet with a finished product thickness of 0.15 mm is obtained by rolling, the total processing rate is 25%, the surface is bright and consistent, and the detected surface roughness is 0.12 μm.

Embodiment 2

[0029] Take a raw tungsten plate with a thickness of 0.25mm, use 240# water sandpaper to grind the surface of the raw tungsten plate, and then use 1%NaOH+4%K 2 CO 3 +4% KCLO 3 + Yu H 2 O electrolyte, polish for 30min; use fine grinding and rolling work rolls with roughness less than 0.1μm; roll preheating temperature is 150℃; raw tungsten plate preheating temperature is 200℃; surface treated and preheated tungsten plate The preheated four-high reversing rolling mill directly conducts block rolling without coating graphite and other lubricating materials. The initial rolling force is 40T, and then the rolling force is gradually increased. The final rolling force is 60T. After multiple passes A thin tungsten sheet with a finished product thickness of 0.2 mm is obtained by rolling, the total processing rate is 20%, the surface is bright and consistent, and the detected surface roughness is 0.14 μm.

Embodiment 3

[0031] Take a raw tungsten plate with a thickness of 0.2mm, use 240# water sandpaper to grind the surface of the raw tungsten plate, and then use 1%NaOH+4%K 2 CO 3 +4% KCLO 3 + Yu H 2 O electrolyte, polish for 10min; use fine grinding and rolling work rolls with roughness less than 0.1μm; roll preheating temperature is 120℃; raw tungsten plate preheating temperature is 150℃; The preheated four-high reversing rolling mill directly performs block rolling without coating graphite and other lubricating materials. The initial rolling force is 40T, and then the rolling force is gradually increased. The final rolling force is 100T. After multiple passes A thin tungsten sheet with a finished product thickness of 0.14 mm is obtained by rolling, the total processing rate is 30%, the surface is bright and consistent, and the detected surface roughness is 0.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com